Device and method for producing fiber-filled starch-based fully biodegradable material

A degradable material and starch-based technology, which is applied in the field of producing fiber-filled starch-based fully biodegradable materials, can solve the problems that the material cannot be completely degraded, the product cost performance cannot be compared with ordinary plastics, etc., and achieves good cooling effect and good modification effect. , the effect of reducing the number of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Use the formula described in the table below:

[0069]

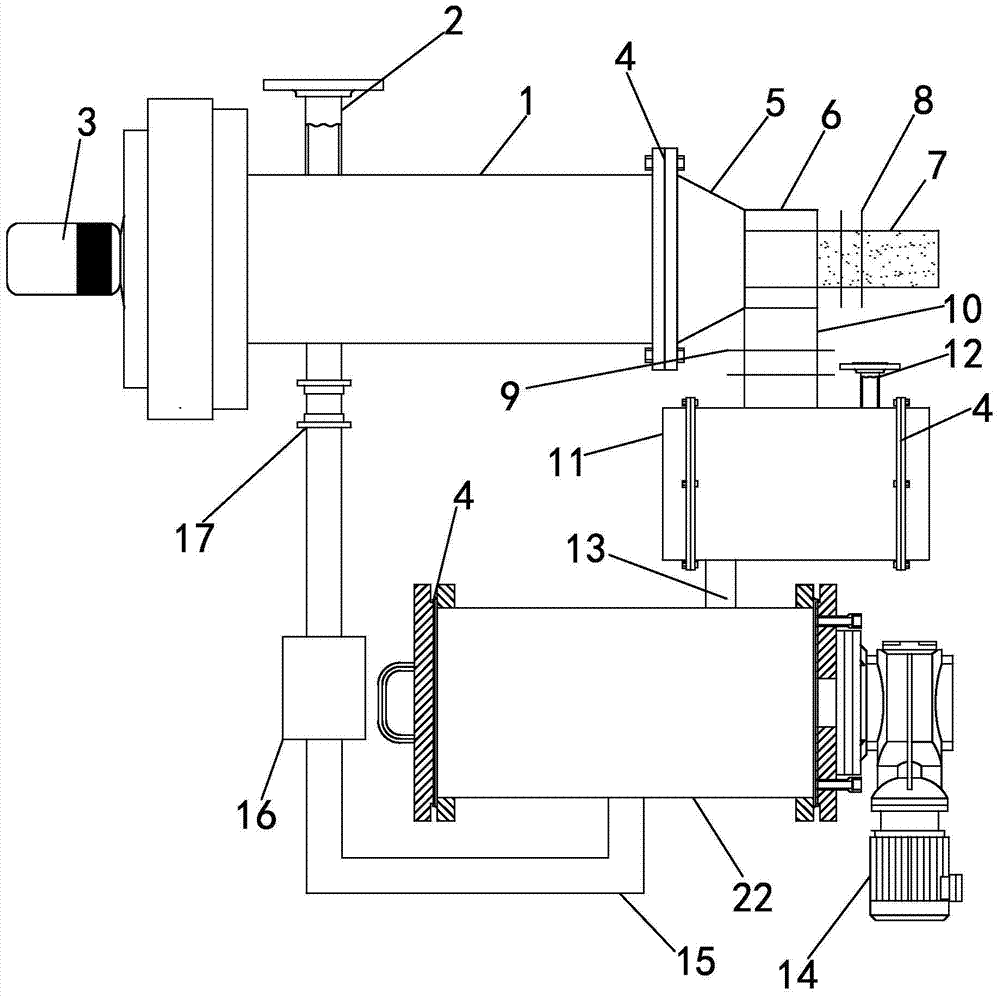

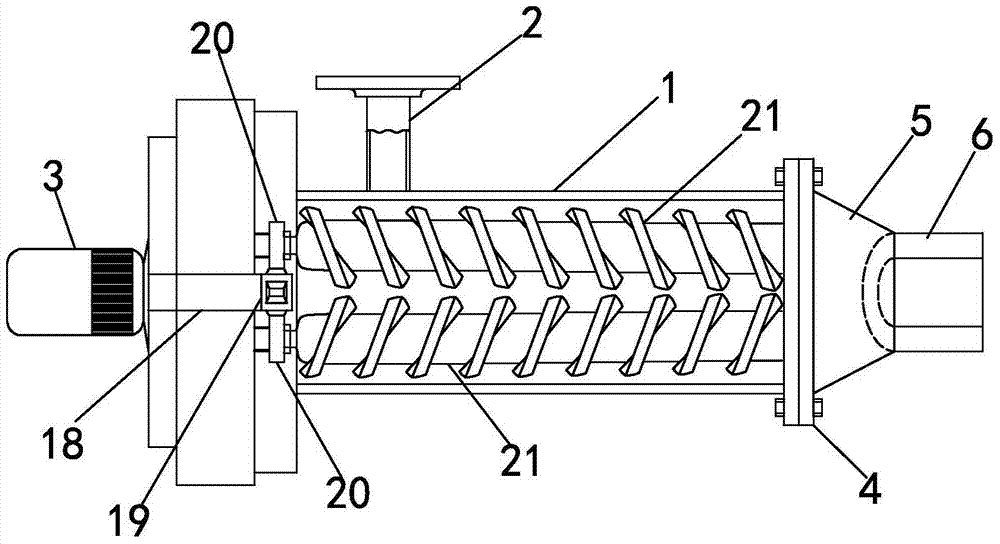

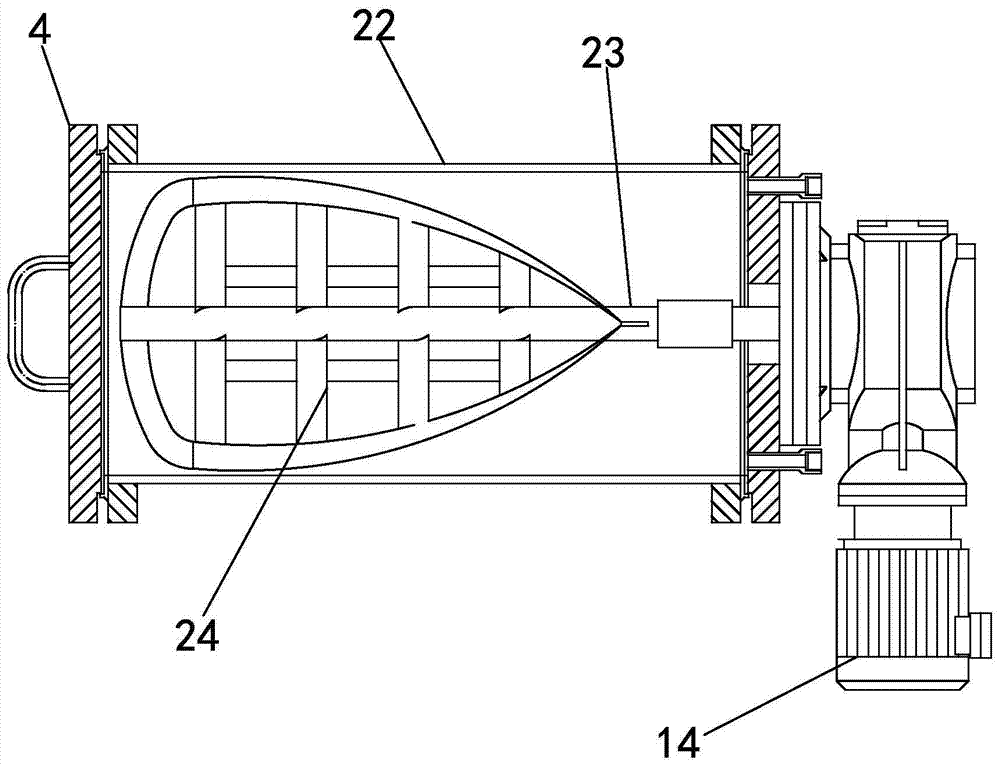

[0070] Get 35g bamboo cellulose, 0.2g chloroacetyl, 0.1g cerium nitrate ammonium solution, 1g plasticizer and 0.3g coupling agent, turn on the first motor 3, control the rotating speed of the screw rod 21 to be 520rpm, and the graft modification time is 11min , finally obtain the mixture; the mixture enters the melting furnace 11 through the mud nozzle 6, and adds 50g starch, 5g polylactic acid, 7g polybutylene succinate, 1g plasticizer, 0.3g coupling agent through the second feed port 12 And 0.1g antioxidant is added in the melting furnace 11, and the temperature in the melting furnace 11 is controlled at 270°C, and melted for 20 minutes to obtain the first molten mixture; the first molten mixture is transported to the high-speed mixer 22 through the second feed pipe 13 Inside, turn on the second motor 14, control the rotating speed of the stirring paddle 24 to 1200 rpm, and mix at a high speed for 1.5 hours t...

Embodiment 2

[0080] Use the formula described in the table below:

[0081]

[0082] Get 20g bamboo cellulose, 0.3g chloroacetyl, 0.05g cerium nitrate ammonium solution, 0.5g plasticizer and 0.25g coupling agent, open the first motor 3, the rotating speed of control screw rod 21 is 520rpm, and graft modification time is 12min, finally obtains mixture; Mixture enters melting furnace 11 by mud nozzle 6, adds 60g starch, 10g polylactic acid, 8g polybutylene succinate, 0.5g plasticizer, 0.25g bismuth by second feed port 12 Add the joint agent and 0.15g antioxidant into the melting furnace 11, control the temperature in the melting furnace 11 at 270°C, and melt for 20 minutes to obtain the first molten mixture; the first molten mixture is transported to high-speed mixing through the second feeding pipe 13 In the machine 22, turn on the second motor 14, control the rotating speed of the stirring paddle 24 to be 1200rpm, and mix at a high speed for 1.5 hours to obtain the second molten mixture;...

Embodiment 3

[0093] Use the formula described in the table below:

[0094]

[0095] Get 20g bamboo cellulose, 0.3g chloroacetyl, 0.05g cerium nitrate ammonium solution, 1g plasticizer and 0.25g coupling agent, open the first motor 3, control the rotating speed of the screw rod 21 to be 550rpm, and the graft modification time is 12min , finally obtain the mixture; the mixture enters the melting furnace 11 through the mud nozzle 6, and adds 65g starch, 7g polylactic acid, 5g polybutylene succinate, 1g plasticizer, 0.25g coupling agent through the second feed port 12 And 0.15g of antioxidant is added in the melting furnace 11, the temperature in the melting furnace 11 is controlled at 270° C., and melted for 20 minutes to obtain the first molten mixture; the first molten mixture is transported to the high-speed mixer 22 through the second feeding pipe 13 Inside, turn on the second motor 14, control the rotating speed of the stirring paddle 24 to be 1300rpm, after mixing at high speed for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com