Method for preparing large-flake-diameter graphene oxide from natural flaky graphite

A flake graphite and graphene technology, applied in the field of preparing large-diameter graphene oxide from natural flake graphite, can solve problems such as the influence of the flake diameter, the destruction of the crystal structure, the fracture of carbon-carbon bonds, etc., and achieve a large flake diameter and a wide range of uses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] The method for preparing large-diameter graphene oxide with natural flake graphite comprises steps as follows:

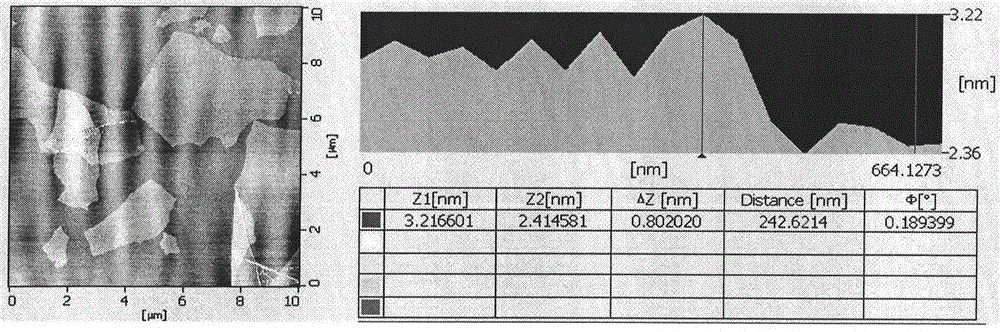

[0035] 1) preparation of graphite oxide suspension; choosing carbon content is 99.5%, and particle size is 200 purpose natural flaky graphite as raw material, adopts improved Hummers method to prepare graphite oxide, promptly according to flaky graphite: the ratio of concentrated sulfuric acid=1Kg: 25L , slowly add natural flake graphite into an acid-resistant reactor filled with concentrated sulfuric acid, fully stir for 30 minutes under ice bath conditions; Potassium acid potassium was slowly added to the above reactor, and stirred for 5 hours at 35°C; finally, 10% hydrogen peroxide and deionized water were slowly added to the reactor in turn, so that the temperature in the reactor was controlled at 60-100°C until There is no longer gas generation in the reactor and the temperature is constant. After adding an appropriate amount of 5% dilute hydrochloric ac...

example 2

[0039] The basic steps of this example are the same as Example 1, the difference lies in:

[0040] Step 1) process graphite oxide suspension; select carbon content as 99.9%, and the natural flake graphite of particle size is 150 objects as raw material, adopts improved Hummers method to prepare graphite oxide, then adds deionized water to obtain graphite oxide solid content is 1 % graphite oxide suspension;

[0041] Step 2) mixing the graphite oxide suspension with deionized water at a volume ratio of 1:50, using a high-speed dispersing homogenizer to stir for 10 min at a speed of 8000 rpm to obtain a large-diameter graphite oxide dispersion mother liquor; and then using Centrifugation removes impurities in the large-diameter graphite oxide dispersion mother liquor to obtain a concentration of 0.2g L -1 Graphene oxide dispersion.

[0042] Such as image 3 Shown, is the 0.2g L that example 2 prepares -1 The photo of the graphene oxide dispersion state, the graphene oxide disp...

example 3

[0044] The basic steps of this example are the same as Example 1, the difference lies in:

[0045] Step 1) processing graphite oxide suspension; choosing carbon content is 98%, and particle size is 100 purpose natural scaly graphites as raw material, adopts improved Hummers method to prepare graphite oxide, then adds deionized water to obtain graphite oxide solid content is 5 % graphite oxide suspension;

[0046] Step 2) The graphite oxide suspension and deionized water are mixed according to the volume ratio of 1:2, and the high-speed dispersing homogenizer is used to stir for 5 minutes at a speed of 10,000 rpm to obtain a large-diameter graphene oxide dispersion mother liquor ; Remove impurities in the large-diameter graphene oxide dispersion mother liquor through flotation, and prepare a concentration of 2g L -1 Graphene oxide dispersion.

[0047] Such as Figure 5 Shown, is the 2g L that example 3 prepares -1 The photo of the state of the graphene oxide dispersion, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com