Preparation method of phenylmethylamine

A technology for benzylamine and benzonitrile, applied in the field of preparation of benzylamine, can solve the problems of high catalyst loss, low production efficiency, high labor intensity, etc., and achieves avoiding high catalyst loss, meeting environmental protection requirements, and achieving good technical effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

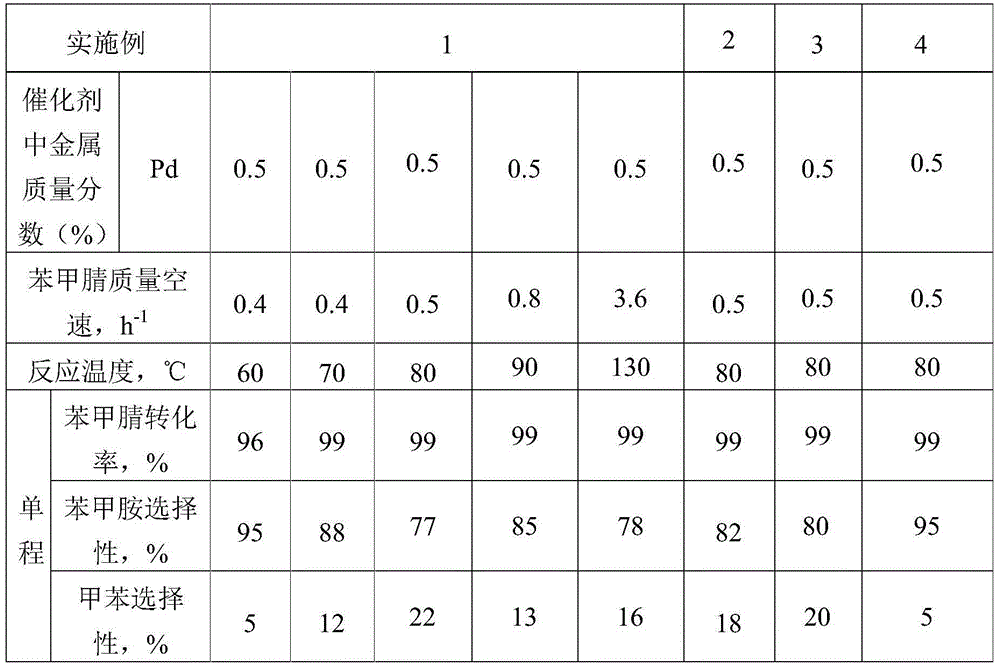

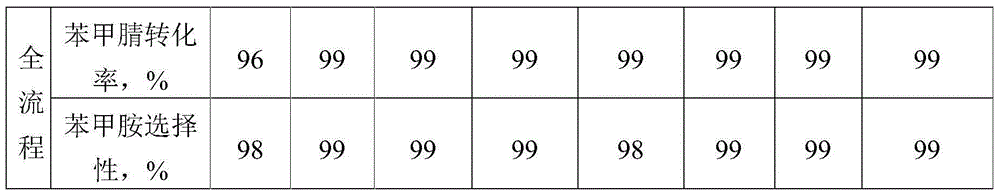

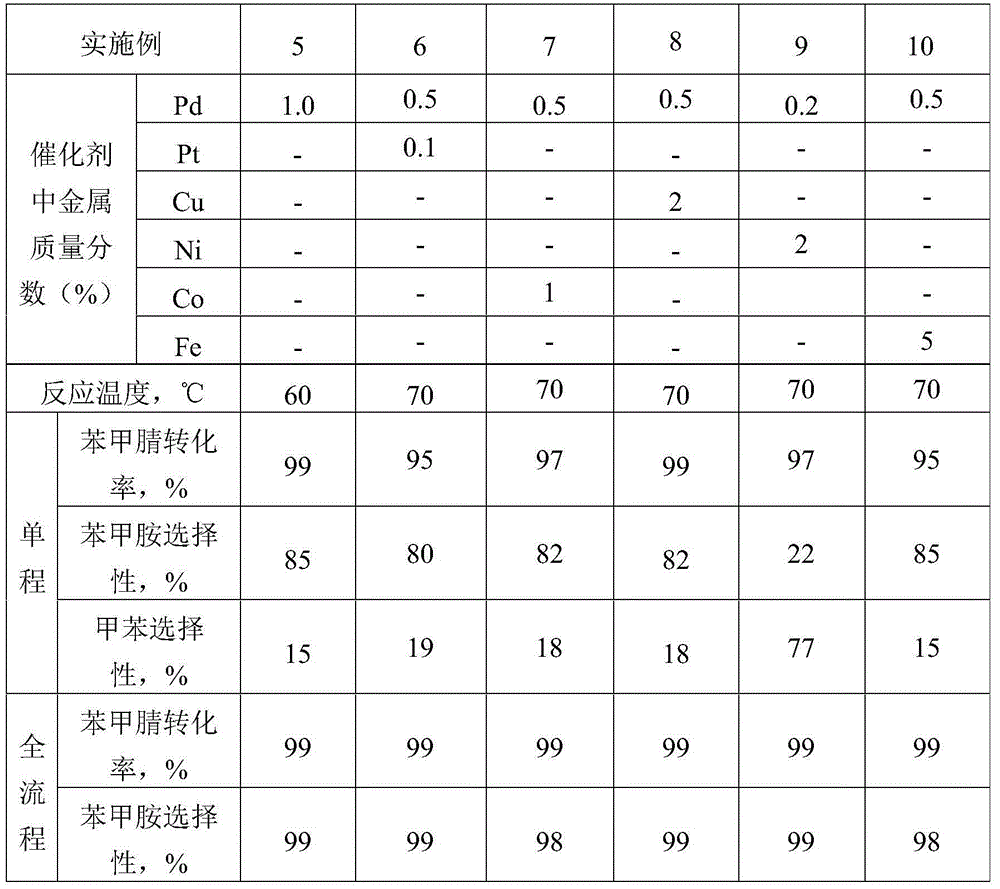

Embodiment 1

[0024] Catalyst preparation: Weigh 3.33g of palladium chloride, add 100g of deionized water to make solution A, take 5g of the above solution and add it into deionized water, add concentrated hydrochloric acid dropwise to adjust the pH of the solution to 0, impregnate until 20g has been broken to 30-50 mesh γ-Al 2 o 3 On the aluminum oxide carrier of type, make the content of metal palladium in the catalyst be 0.5wt%. The support impregnated with the palladium component was dried at 120° C. for 12 h. The dried catalyst was calcined at 500° C. for 4 h in an air atmosphere to obtain a catalyst precursor. Save for later.

[0025] Put the prepared catalyst into a stainless steel fixed-bed reactor with an inner diameter of φ12mm, control the reaction temperature at 40-130°C, and the mass space velocity of benzonitrile at 0.5-3.6h -1 , the weight ratio of the benzonitrile to the solvent is 99:1, and the weight ratio of the part of the product material entering the mixing unit to...

Embodiment 2

[0029] According to the conditions and steps described in Example 1, the weight ratio of the part of the product material entering the mixing unit to benzonitrile is 1:1, and the reaction results are shown in Table 1.

Embodiment 3

[0031] According to the conditions and steps described in Example 1, the solvent is ethanol, and the weight ratio of benzonitrile to ethanol is 1:1. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com