Preparation method of hexafluoropropylene oxide

A technology of hexafluoropropylene oxide and hexafluoropropylene, which is applied in the field of gas-phase oxidation to prepare hexafluoropropylene oxide, can solve the problems of high reaction temperature, low conversion rate, and inaccessibility, and achieve low reaction temperature and fast reaction speed , the effect of less solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] will (HFPO) x Add it to a 1L dry autoclave, seal the autoclave and evacuate it with a vacuum pump for 30 minutes to remove impurity gases. Then inject HFP into the reactor, and maintain the stirring speed at 350rpm. Raise the temperature of the stirred tank body to 90°C~160°C, maintain it for 0.5h~1h until the temperature is stable, and then add oxygen, the oxygen partial pressure ΔP O2 =0.2MPa. After reacting for a certain period of time, the HFP conversion rate and the selectivity of the target product HFPO were detected, and the results are listed in Table 1.

Embodiment 2-8

[0030] Change (HFPO) x Type and consumption, HFP and oxygen consumption, reaction temperature, reaction time etc., all the other are identical with embodiment 1. After reacting for a certain period of time, the HFP conversion rate and the selectivity of the target product HFPO were detected, and the results are listed in Table 1.

[0031] (HFPO) used in Examples 7-8 x Among them, the mass content ratio of dimers, trimers, tetramers and pentamers is about 1:3:3:1.

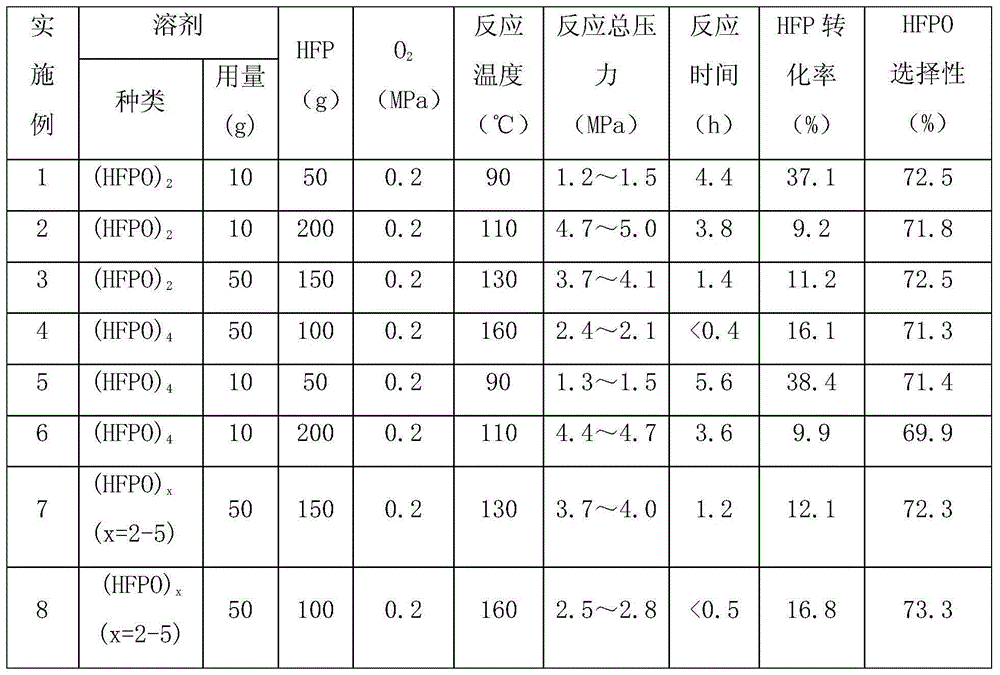

[0032] Table 1

[0033]

[0034] As can be seen from Table 1, using (HFPO) x When used as a solvent for HFP epoxidation, the epoxidation reaction can proceed stably, and the conversion rate of HFP in a single oxygen (0.2MPa) reaction is between 9.2% and 38.4% (relative to HFP. Due to the constant oxygen flow, the conversion rate Depending on the amount of HFP added), the selectivity of the target product HFPO is located at 69.9%-73.3%. Show (HFPO) x It is an ideal reaction solvent.

Embodiment 9

[0036] will (HFPO) 2 Add it to a 1L dry autoclave, seal the autoclave and evacuate it with a vacuum pump for 30 minutes to remove impurity gases. Then, 100 g of HFP was injected into the reactor, and the stirring speed was maintained at 350 rpm. Raise the temperature of the stirred tank to 130°C and maintain it for 0.5h to 1h until the temperature is stable, then add oxygen in 6 times, each time the oxygen partial pressure ΔP O2 =0.2MPa. After reacting for a certain period of time, the conversion rate of HFP and the selectivity of the target product HFPO were detected after each addition of oxygen.

[0037] The total reaction time of this reaction was 5.16h, the final conversion rate of HFP reached 100%, and the selectivity of the target product HFPO was 72.1%.

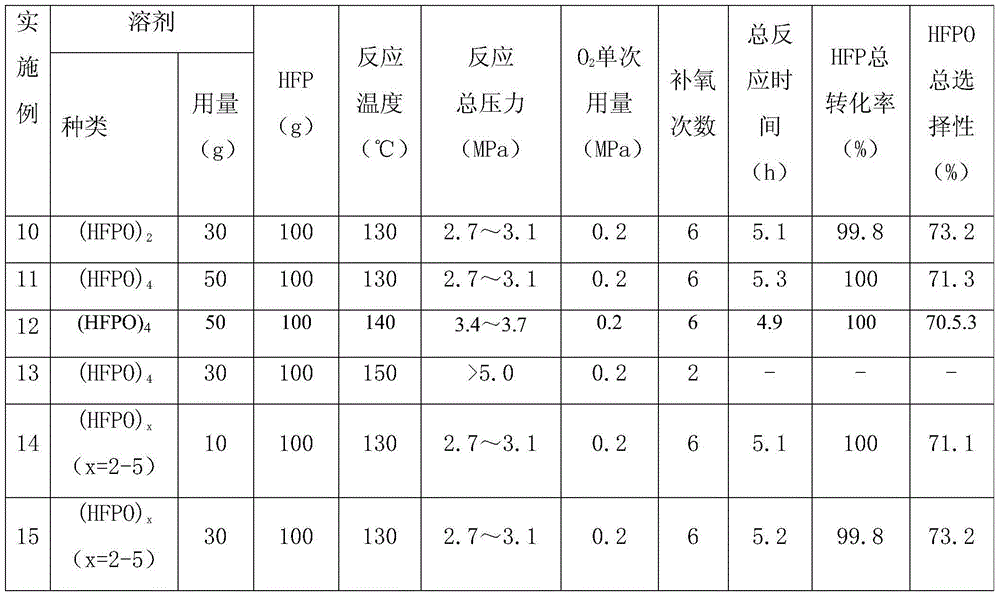

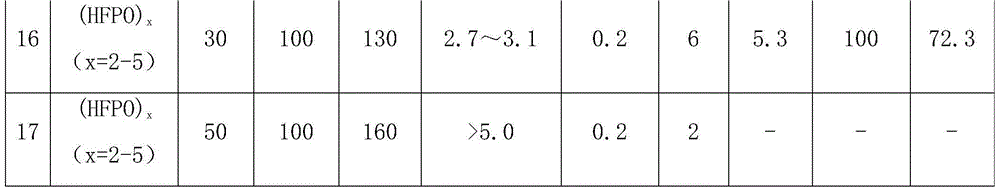

[0038] Table 2

[0039] Oxygen addition times

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com