Manufacturing method of polyacetal copolymer

A technology of polyacetal copolymer and manufacturing method, which is applied in the field of polyacetal copolymer manufacturing, can solve the problems of supply, reduction of polymerization yield, and inability to stabilize raw materials, etc., so as to reduce fouling and maintain polymerization yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] A biaxial paddle type continuous polymerization reactor (manufactured by Kurimoto Iron Works Co., Ltd., diameter 2B (2 inches), L (distance from the raw material supply port to the discharge port of the polymerization reactor) / D (the inner diameter of the polymerization reactor) = 14.8) was adjusted to 80°C.

[0146] Cyclohexane as an organic solvent (boiling point: 80.74° C.) and IRGANOX 1010 as an antioxidant were prepared as an organic solvent mixed solution (I) with a mass ratio of organic solvent:antioxidant=540:1.

[0147] Next, 0.18 g / hour of boron trifluoride-di-n-butyl ether complex as a polymerization catalyst, 0.24 g / hour of formal as a low molecular weight acetal, and 6.50 g of the above-mentioned organic solvent mixture (I) / hour and 1,3-dioxolane as a cyclic ether and / or cyclic formal are continuously premixed at 120.9g / hour at a temperature of 30°C and a mixing time of 2 minutes to obtain a premixed Mixture.

[0148] In addition, a static mixer was use...

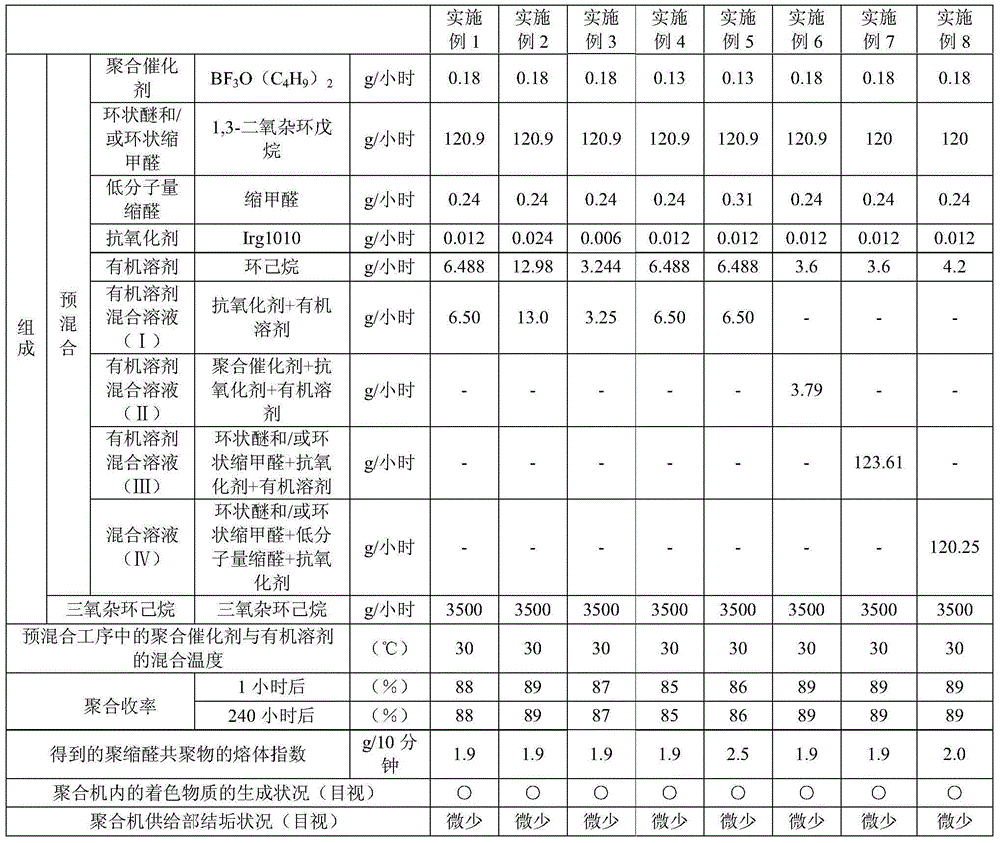

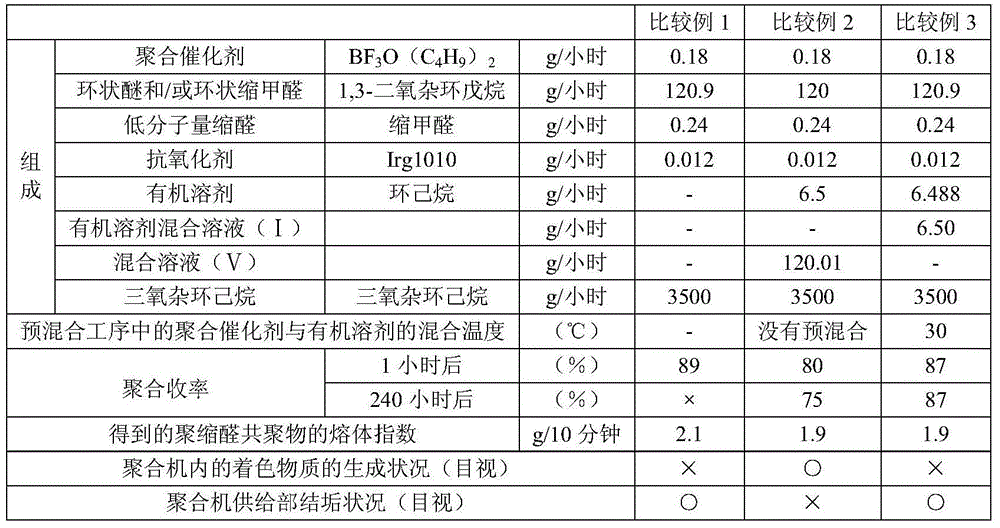

Embodiment 2~5

[0155] The composition of the raw materials and the preparation conditions of the premix solution were changed as shown in Table 1 below.

[0156] Other conditions were the same as in Example 1 to obtain a polyacetal copolymer.

[0157] The evaluation results are shown in Table 1 below.

Embodiment 6

[0159] A twin-shaft paddle type continuous polymerization reactor (manufactured by Kurimoto Iron Works, diameter 2B, L / D=14.8) equipped with a jacket through which a heat medium can flow was adjusted to 80°C.

[0160] Boron trifluoride-di-n-butyl ether complex as a polymerization catalyst, cyclohexane as an organic solvent and IRGANOX1010 as an antioxidant were prepared as polymerization catalyst in mass ratio: organic solvent: antioxidant=15:300: 1 organic solvent mixed solution (II).

[0161] Next, 0.24 g / hour of formal as a low molecular weight acetal, 3.79 g / hour of the above-mentioned organic solvent mixture (II), 1,3-dioxa as cyclic ether and / or cyclic formal Cyclopentane was continuously premixed at 120.9 g / hour at a temperature of 30° C. and a mixing time of 2 minutes to obtain a premix liquid.

[0162] In addition, a static mixer was used in the preparation of the above-mentioned premix liquid.

[0163] The above-mentioned premixed solution was continuously supplied t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com