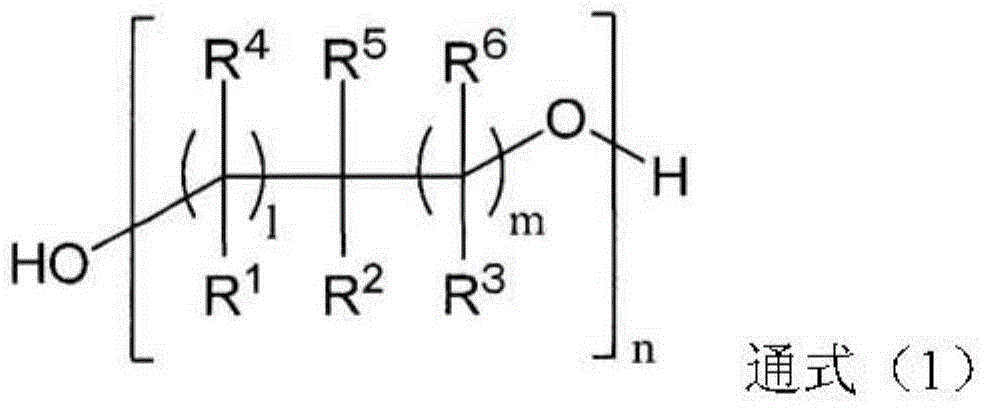

Polyfunctional acid anhydride, a thermosetting resin composition and its cured prepreg

A technology of thermosetting resin and polyfunctional acid anhydride, applied in the field of polyfunctional acid anhydride and thermosetting resin composition, can solve the problems of insufficient heat resistance and insufficient transparency of cured products, and achieve excellent coloring resistance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Next, the present invention will be described in more detail based on examples. In addition, this invention is not limited at all by the following Examples. In the synthesis of the compound, when the disappearance of the raw material alcohol was confirmed by gel permeation chromatography (hereinafter referred to as "GPC"), the reaction was regarded as complete. In addition, in the examples, TMAC represents trimellitic anhydride acid chloride, HTAC represents nuclear hydrogenated trimellitic anhydride acid chloride, THF represents tetrahydrofuran, TMP represents trimethanol propane, DPE represents dipentaerythritol, PE4EO represents pentaerythritol 4 moles of ethylene oxide plus The finished product, DE6EO means dipentaerythritol 6 mole ethylene oxide adduct, DPE4C means dipentaerythritol 4 mole caprolactone adduct, MEK means methyl ethyl ketone.

Synthetic example 1

[0122] Synthesis Example 1: Synthesis of Dipentaerythritol 4 Mole Caprolactone Adduct (DPE4C)

[0123] In a flask equipped with a stirrer, a reflux cooling tube, and a stirring device, 45.66 g (400 mmol) of caprolactone was added to 25.43 g (100 mmol) of dipentaerythritol, and stirred at 180° C. for 12 hours to obtain di Pentaerythritol 4 mole caprolactone adduct 71.09g.

Synthetic example 2

[0124] Synthesis Example 2: Preparation of Copolymerized Epoxy Resin

[0125] In a flask equipped with a stirrer, a reflux cooling tube, and a stirring device, 30 g of glycidyl methacrylate, 30 g of methyl methacrylate, 40 g of butyl methacrylate, and methyl ethyl methacrylate as a solvent were added while purging nitrogen gas. 200 g of ketones and 1 g of azobisisobutyronitrile as a reaction initiator were subjected to a polymerization reaction at 80° C. for 5 hours.

[0126] After completion|finish of reaction, it heated to 90 degreeC, the solvent was distilled off under reduced pressure, and the copolymer type epoxy resin was obtained. The molecular weight of the obtained copolymer epoxy resin was 15,000 in terms of polystyrene by GPC, the number average molecular weight was 30,000, and the epoxy equivalent was 470 g / eq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com