Environment-friendly type self-polishing anti-fouling paint with high adhesive force

A high-adhesion, self-polishing technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve problems that do not conform to actual conditions and short intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

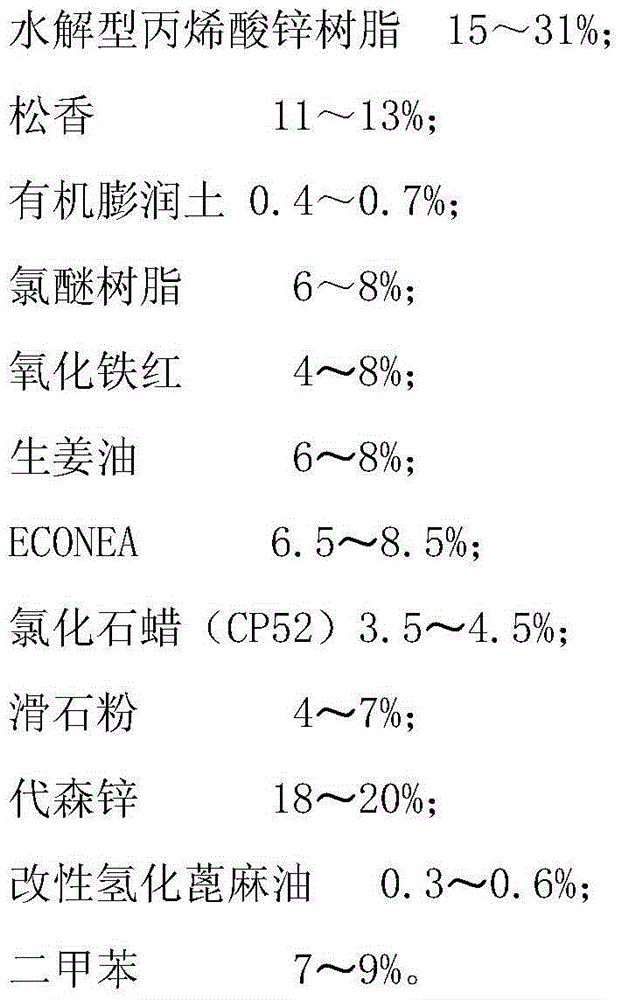

[0039] (1) An environment-friendly high-adhesion self-polishing antifouling paint, the weight percentage of each raw material in its components is:

[0040] Hydrolyzed acrylate zinc resin 31%, adopts 9115 resin produced by Shanghai Zhongqu Chemical Co., Ltd.

[0041] Rosin 11%, adopts the product produced by Junneng Chemical Co., Ltd.

[0042] Organic bentonite 0.4%, adopts the product of BENGEL958 produced by Hemings.

[0043] Chlorine ether resin 6%, adopt the product that BASF produces, product name is LAROFLEX MP-45.

[0044] Iron oxide red 4%, the product named S-190 produced by Shanghai Yipin Pigment.

[0045] Ginger oil 6%, the product produced by Ji'an Shengda Perfume Oil Co., Ltd.

[0046] ECONEA 8.5%, using products produced by Johnson & Johnson.

[0047] Chlorinated paraffin (CP52) 3.5%, the product produced by Nanjing Xinyuan Chemical Co., Ltd.

[0048] Talcum powder 4%, adopt the product that Laizhou Yudong Company produces, product name is TL-3.

[0049] Zi...

Embodiment 2

[0062](1) An environment-friendly high-adhesion self-polishing antifouling paint, the weight percentage of each raw material in its components is:

[0063] Hydrolyzable type acrylate zinc resin 15% (the raw material that adopts is the same as embodiment 1).

[0064] Rosin 13% (the raw material that adopts is with embodiment 1).

[0065] Organic bentonite 0.7% (the raw material that adopts is the same as embodiment 1).

[0066] Chlorine ether resin 8% (the raw material that adopts is with embodiment 1).

[0067] Iron oxide red 8% (the raw material that adopts is the same as embodiment 1).

[0068] Ginger oil 8% (the raw material that adopts is the same as embodiment 1).

[0069] ECONEA 6.5% (the raw material that adopts is the same as embodiment 1).

[0070] Chlorinated paraffin (CP52) 4.5% (the raw material that adopts is the same as embodiment 1).

[0071] Talcum powder 7% (the raw material that adopts is with embodiment 1).

[0072] Zinc 20% (the raw material that adop...

Embodiment 3

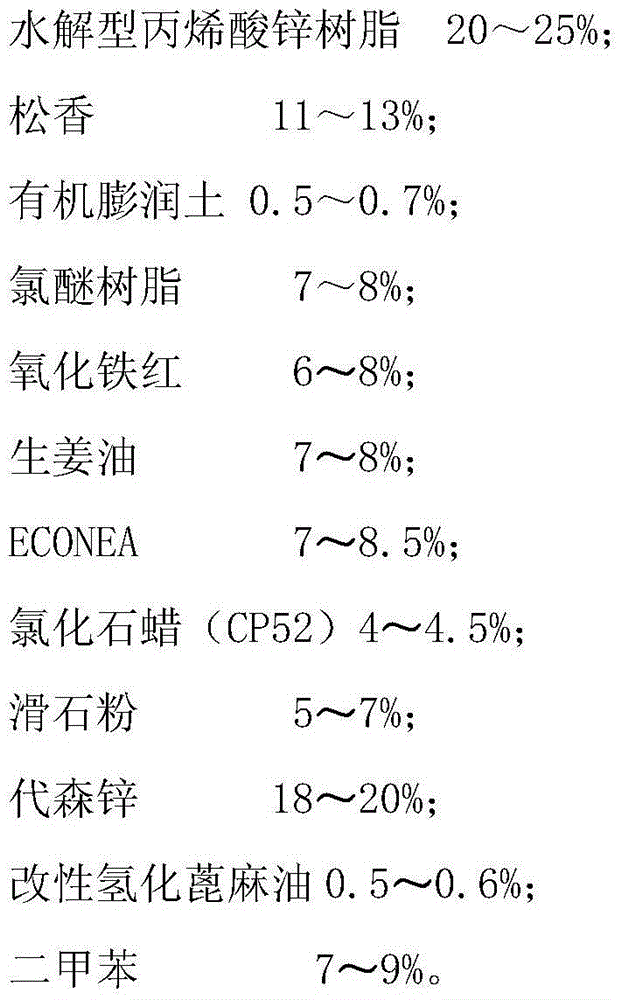

[0078] (1) An environment-friendly high-adhesion self-polishing antifouling paint, the weight percentage of each raw material in its components is:

[0079] Hydrolyzable type zinc acrylate resin 20% (the raw material that adopts is the same as embodiment 1).

[0080] Rosin 13% (the raw material that adopts is with embodiment 1).

[0081] Organic bentonite 0.5% (the raw material that adopts is the same as embodiment 1).

[0082] Chlorine ether resin 7% (the raw material that adopts is the same as embodiment 1).

[0083] Iron oxide red 7% (the raw material that adopts is the same as embodiment 1).

[0084] Ginger oil 8% (the raw material that adopts is the same as embodiment 1).

[0085] ECONEA 7% (the raw material that adopts is with embodiment 1).

[0086] Chlorinated paraffin (CP52) 4% (the raw material that adopts is the same as embodiment 1).

[0087] Talcum powder 4% (the raw material that adopts is with embodiment 1).

[0088] Zinc 20% (the raw material that adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com