Preparing for all-fluoroalkyl compound containing active end group and application thereof

A technology of perfluoroalkyl and active end groups, applied in the field of coatings, can solve problems such as difficulty in utilization and insolubility, and achieve the effects of ensuring communication quality, improving navigation speed, and excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

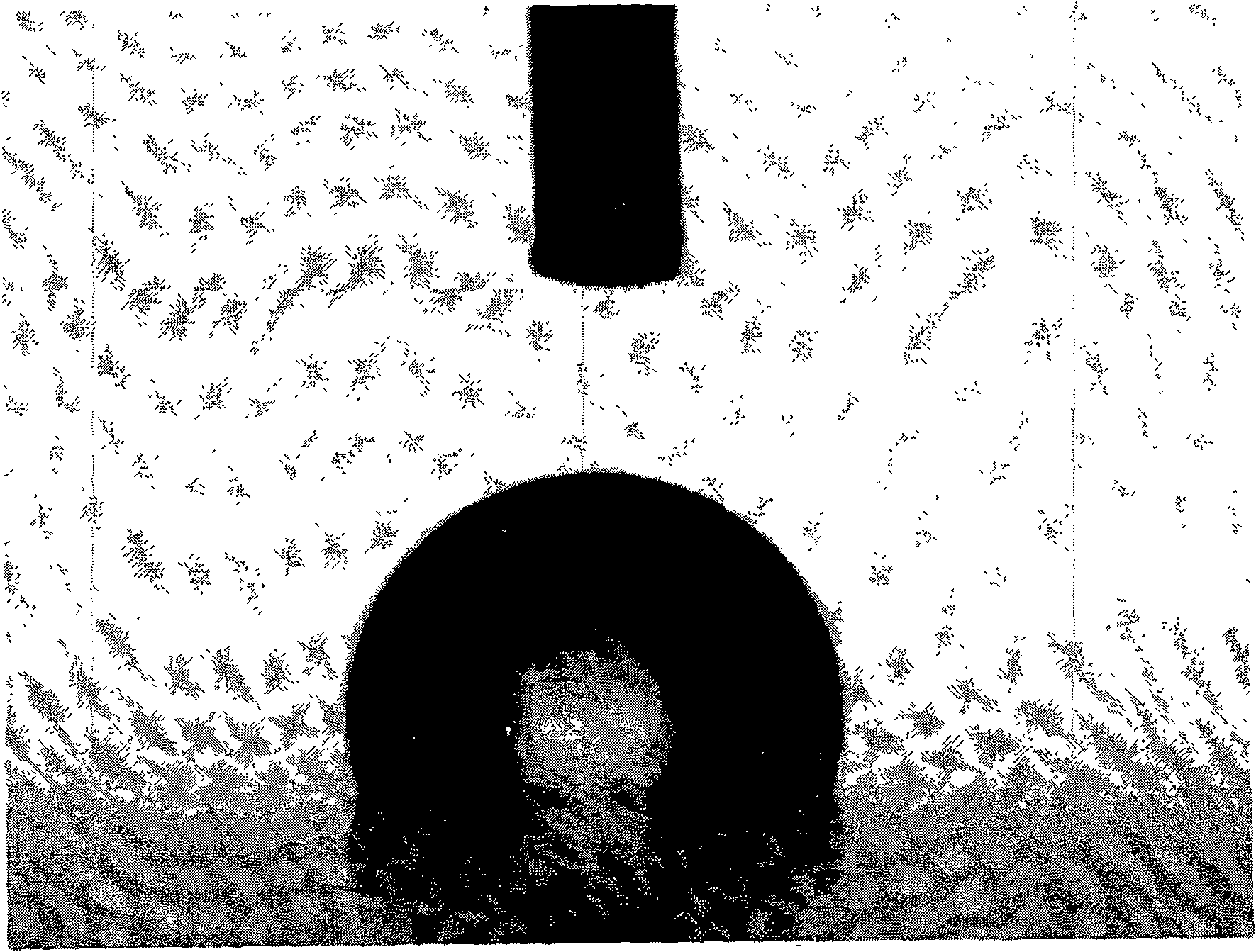

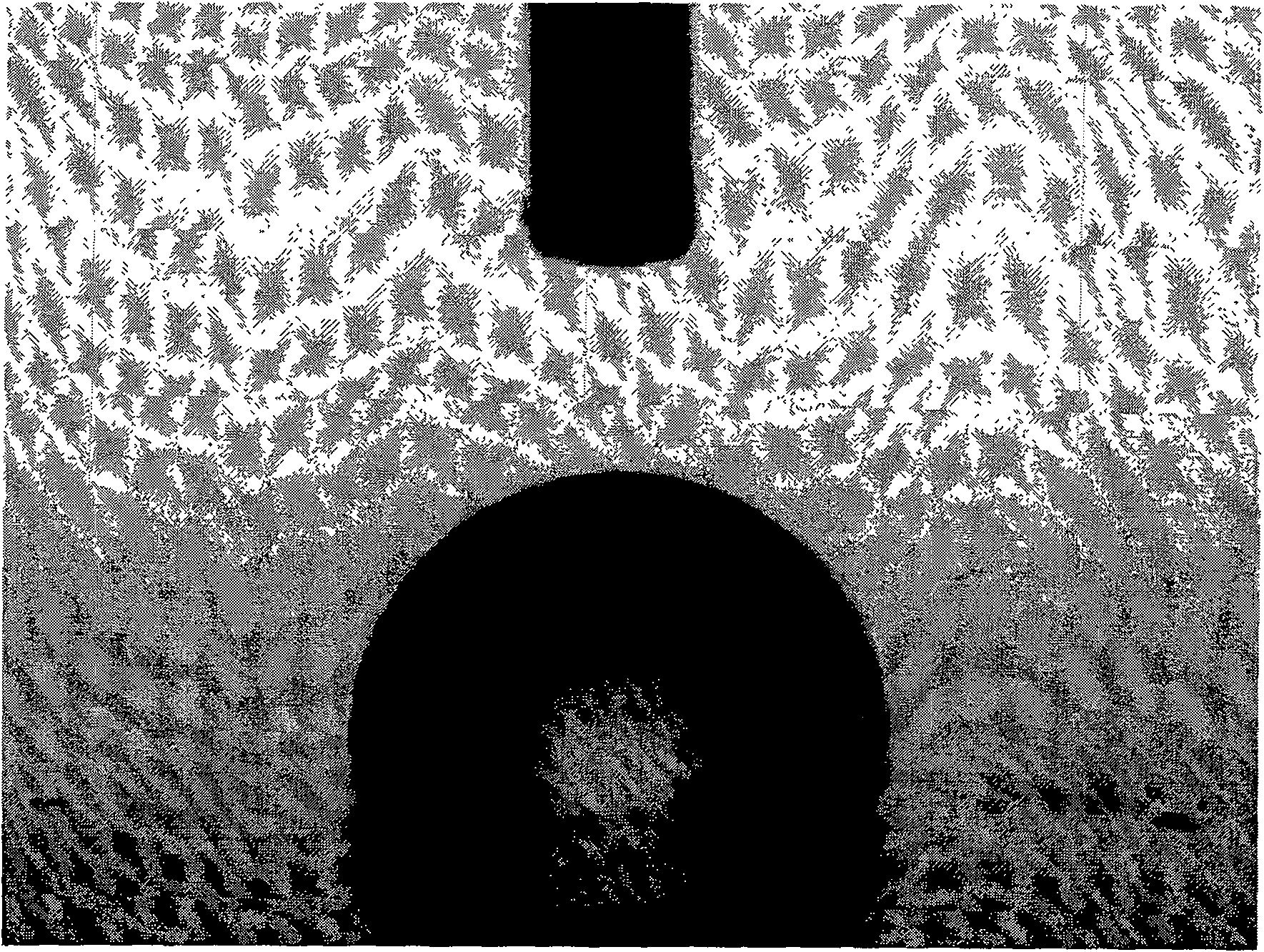

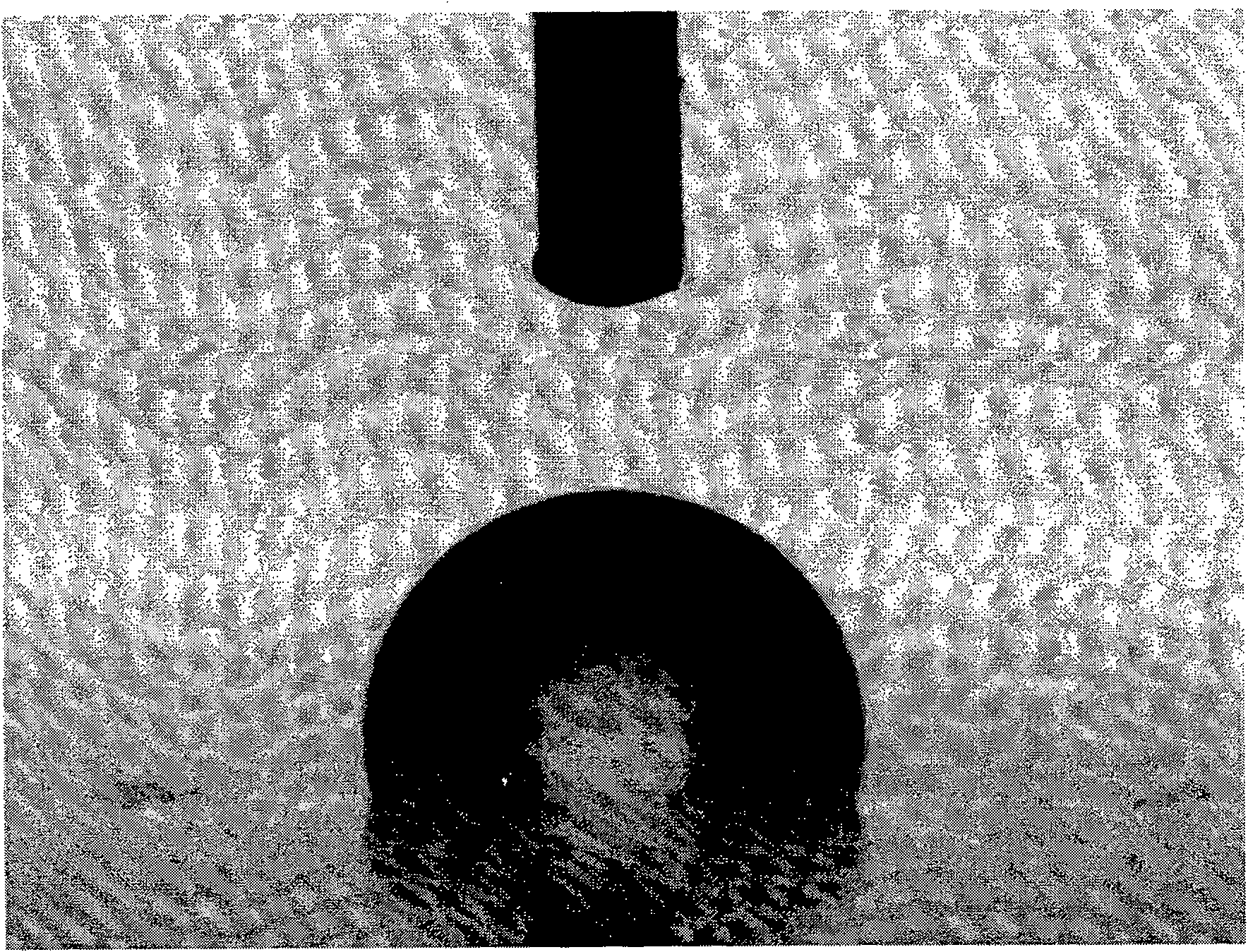

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of a mixture of perfluoroalkyl compounds containing active end groups

[0037] Dissolve 60 parts of toluene diisocyanate in 140 parts of ethyl acetate, add 0.5 parts of dibutyltin dilaurate, and then add 800 parts of perfluoroalkylethanol. The reaction was stirred at 0-25°C for 4 hours and then at 60-80°C for 8 hours. After the reactant was cooled to room temperature, 1000 parts of a homogeneous liquid were obtained.

Embodiment 2

[0038] Example 2: Preparation of a mixture of perfluoroalkyl compounds containing active end groups

[0039] Dissolve 40 parts of diphenylmethane diisocyanate in 200 parts of ethyl acetate, add 0.5 parts of dibutyltin dilaurate, and then add 700 parts of perfluoroalkylethanol. The reaction was stirred at 0-25°C for 2 hours and then at 60-80°C for 6 hours. After the reactant was cooled to room temperature, 1000 parts of a homogeneous liquid were obtained.

Embodiment 3

[0040] Embodiment 3: the preparation of low surface energy coating

[0041] The product of Example 1 is coordinated with acrylic resin (brand BS2150), prepared according to the following steps:

[0042] Component A: 100 parts of BS2150 acrylic resin, 60 parts of pigments and fillers (30 parts of iron oxide red, 20 parts of zinc oxide and 10 parts of heavy calcium carbonate) and 60 parts of diluent (mixed with 50 parts of xylene and 10 parts of acetone) Add it into the container, disperse at a high speed of 2000rpm for 2 hours, when the fineness is 30-50μm, filter it with a 100-mesh filter, measure and pack;

[0043] B component is the product of embodiment 1;

[0044] After uniformly mixing components A and B at a weight ratio of 5:1, it is applied by spraying process, cured at room temperature, and the curing time is more than 10 hours to obtain a smooth and flat low surface energy coating. The water contact angle measurement of the surface energy of the coating reaches 109...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com