Water-based drilling fluid and preparation method thereof

A water-based drilling fluid and drilling fluid technology, which is applied in the field of oil drilling, can solve the problems of inability to effectively solve the instability of hard and brittle mud shale, increase the dosage of conventional plugging agents, and drop blocks in the well, etc. Production application, reducing downhole block drop, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

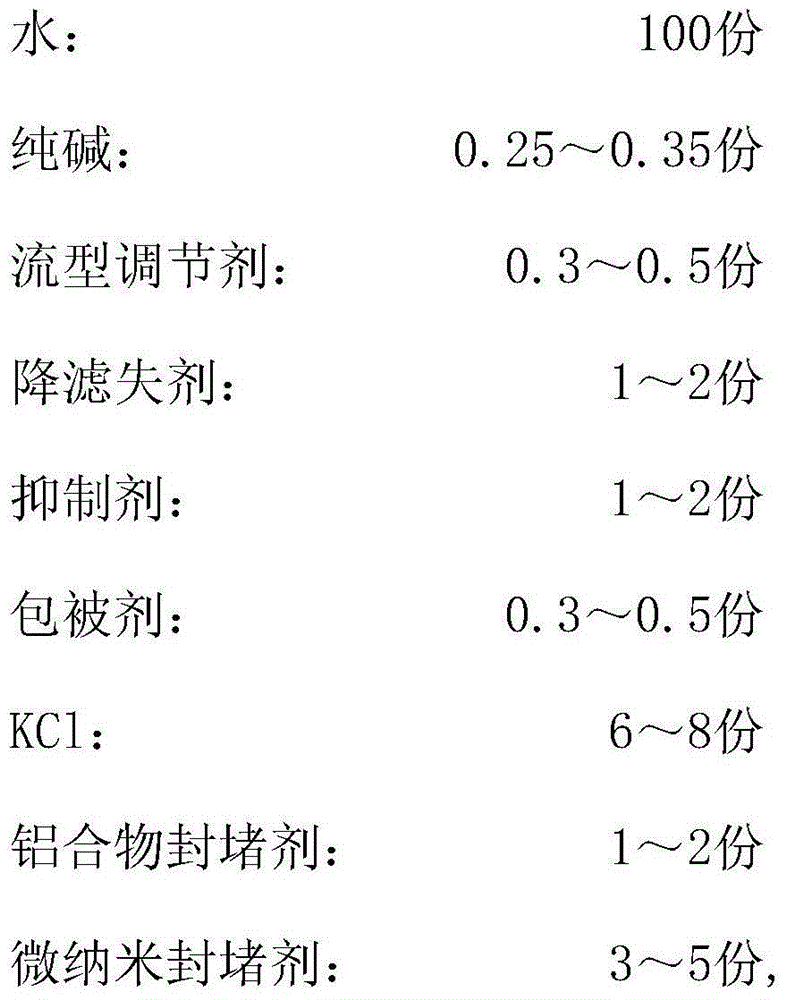

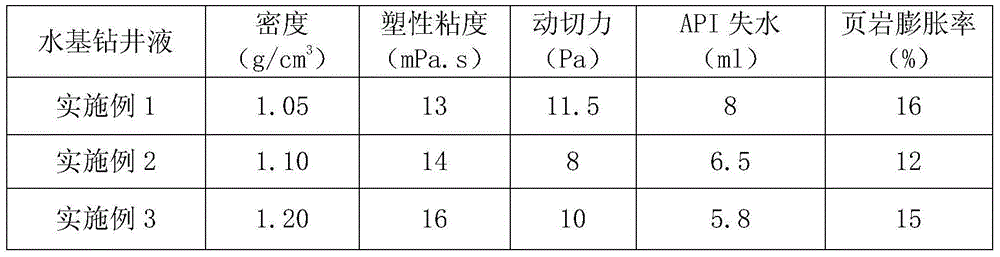

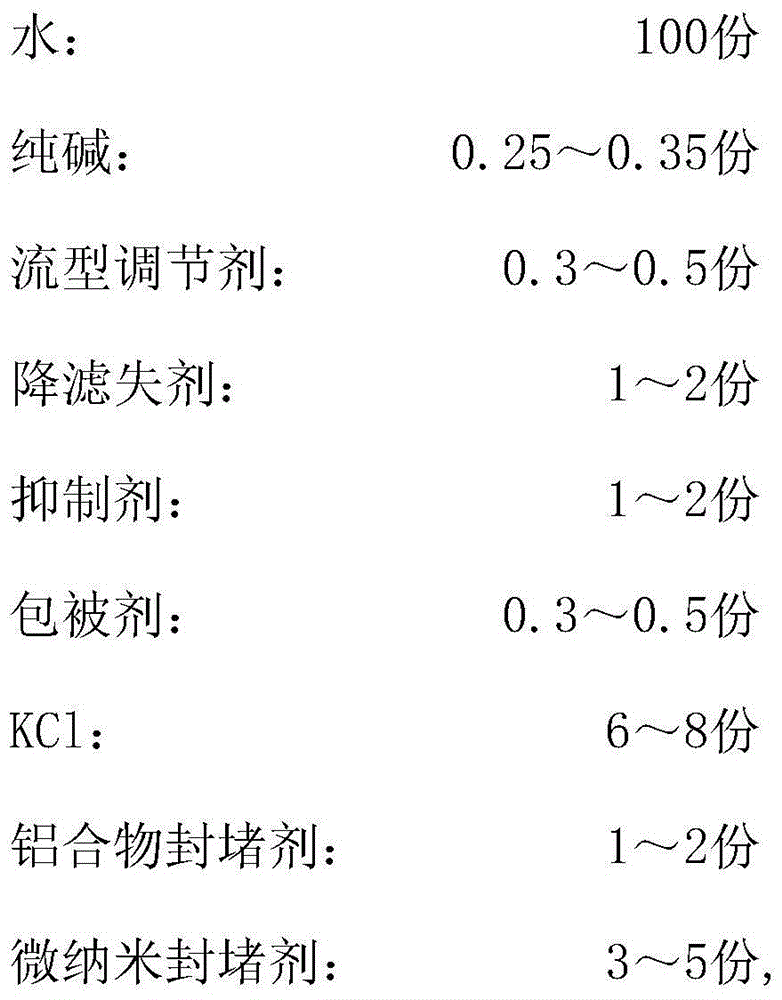

Embodiment 1

[0021] In parts by weight, add 0.25 parts of soda ash, 0.3 parts of high-viscosity xanthan gum, 1 part of low-viscosity anionic cellulose for drilling fluid, 1 part of polyamine inhibitor, 0.5 parts of cationic poly Acrylamide, 6 parts of industrial grade KCl, 1 part of aluminum compound plugging agent, 1 part of micron-sized superfine calcium carbonate and 1 part of nano-sized silicon dioxide, the final density is 4.1g / cm 3 The drilling fluid uses barite powder to increase the density of the drilling fluid system to 1.05g / cm 3 , to obtain the water-based drilling fluid.

Embodiment 2

[0023] In parts by weight, add 0.3 parts of soda ash, 0.5 parts of low-viscosity xanthan gum, 1.5 parts of modified starch, 2 parts of polyamine inhibitors for BZ-JAI drilling fluid, and 0.3 parts of PAC141 to 100 parts of water in a fully stirred state. Coating agent for type drilling fluid, 8 parts of industrial grade KCl, 2 parts of aluminum compound plugging agent for BZ-Alseal type drilling fluid, 2 parts of micron-sized ultrafine calcium carbonate and 3 parts of nano-sized silicon dioxide, and finally add density 4.0g / cm 3 The drilling fluid uses barite powder to increase the density of the drilling fluid system to 1.10g / cm 3 , to obtain the water-based drilling fluid.

Embodiment 3

[0025] In parts by weight, add 0.35 parts of soda ash, 0.25 parts of high-viscosity xanthan gum, 0.25 parts of low-viscosity xanthan gum, and 1 part of low-viscosity polyanionic cellulose for drilling fluid to 100 parts of water successively under stirring at 10,000 rpm , 1 part of modified starch, 2 parts of polyamine inhibitor for BZ-JAI drilling fluid, 0.3 part of potassium polyacrylate, 7 parts of industrial grade KCl, 1 part of aluminum compound plugging agent for BZ-Alseal drilling fluid, 1 1 part of micron-sized superfine calcium carbonate and 1 part of nano-sized silicon dioxide, the final density is 4.2g / cm 3 The drilling fluid uses barite powder to increase the density of the drilling fluid system to 1.20g / cm 3 , to obtain the water-based drilling fluid. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com