Preparation method of antireflection film allowing wide-angle incidence of infrared optical waveband in silicon or germanium base

A technology in infrared optics and substrates, used in sputtering, ion implantation, metal material coating, etc. The problems of reduced capacity, difficult film system design and process, etc., can achieve the effect of high film layer firmness and high density, temperature shock resistance, deliquescence resistance and laser damage resistance, and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the present invention, first use the advanced optical thin film design software (TFCalc) of the United States to design the optimized film system that meets the technical index requirements of the present invention. Coating on the surface of the optically processed silicon material, use the film system design formula: G / 0.2L(5H5L)^50.2L / Air to optimize and calculate the optical thickness value of each layer of film and list them in order. In the formula, G is the substrate of silicon material, L is the refractive index N L Al = 1.60 2 o 3 Film material, H is the refractive index N H = ZnS film material of 2.20, Air is the refractive index N A = 1 air medium, film system reference wavelength λ c = 800nm. The above H and L are granular film materials with a purity of 99.9%. Specific steps include:

[0023] (1) For a hard moisture-proof film layer based on silicon or germanium materials and insulating the surface of silicon or germanium materials from c...

Embodiment 2

[0051] According to the optical thickness value of each layer of 9 layers of film design in the following table 2, repeat the method of experimental embodiment 1, adopt the optimal film system formula of the present invention and each layer optical thickness of table 2, in the coating process step:

[0052] (1) repeat process step (1) in embodiment 1;

[0053] (2) repeat process step (2) in embodiment 1;

[0054] (3) repeat process step (3) in embodiment 1;

[0055] (4) repeat process step (4) in embodiment 1;

[0056] (5) repeat process step (5) in embodiment 1;

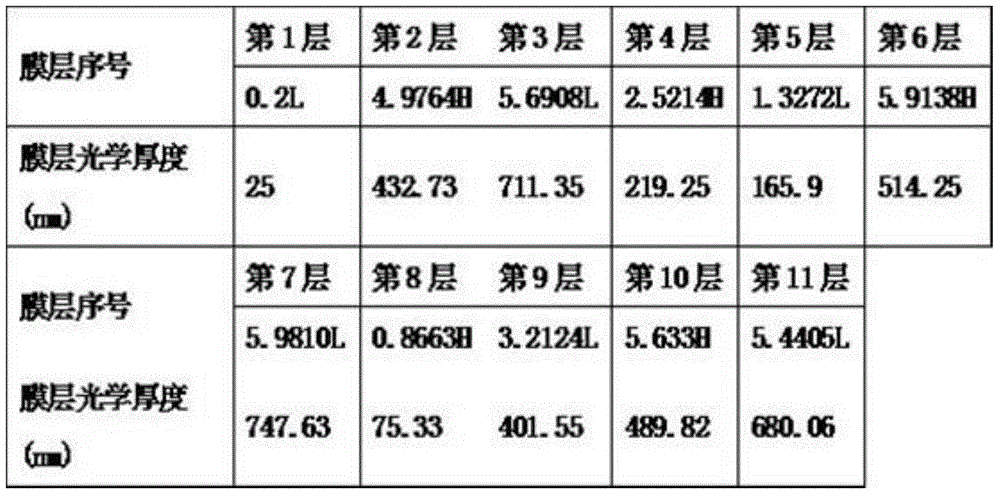

[0057] The actual optical thickness of each layer recorded after the coating is completed is shown in Table 2:

[0058] Table 2 (the optical thickness value table of the germanium 9-layer film that embodiment 2 is actually plated)

[0059]

[0060] Note: The value after the decimal point is not taken, because the precision is enough to meet the design plan.

[0061] (6) Annealing treatment: repeat process st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com