Direct driven high-speed turbine vacuum pump and operation method thereof

A vacuum pump and high-speed technology, applied in the field of direct-drive high-speed turbo vacuum pump, can solve the problems of many hidden trouble spots, high power consumption or water consumption, and large loss of speed-up transmission, so as to achieve low construction and operation costs, and easy dynamic supply and demand. Balance, the effect of variable frequency and variable speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

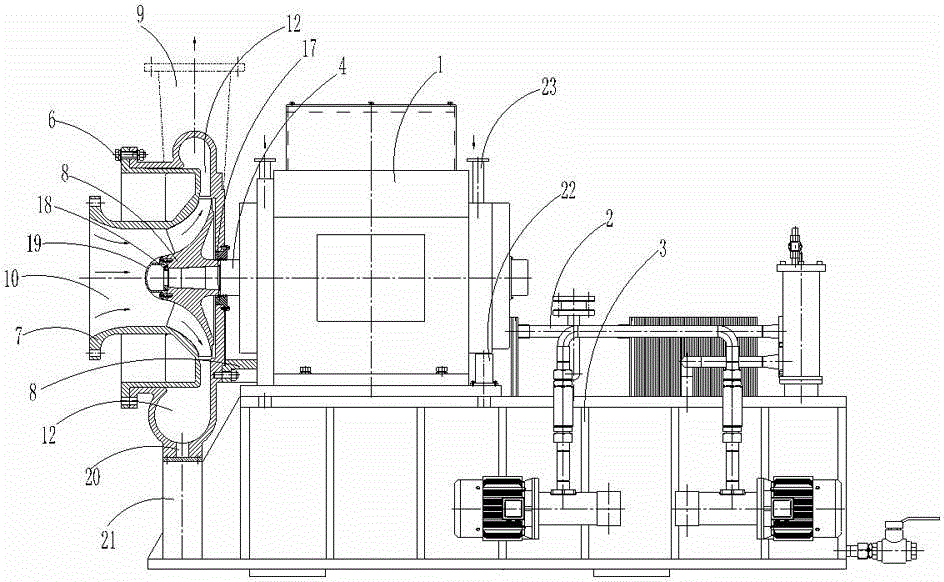

[0043] Embodiment 1: as figure 1 As shown, a direct-drive high-speed turbo vacuum pump includes a direct-connected high-speed motor 1, the direct-connected high-speed motor 1 communicates with a lubricating oil station 2, and the direct-connected high-speed motor 1 is arranged on a platform 3, The direct-coupled high-speed motor 1 is provided with a main shaft 4;

[0044] One end of the direct-coupled high-speed motor 1 is provided with an impeller mechanism, and the impeller mechanism includes a volute 5, a type ring 6 and a turbine impeller 7, and one of the outer ends of the main shaft 4 is provided with a turbine. The impeller 7, the volute 5 is positioned with the direct-connected high-speed motor 1 through the double bracket 8, the turbine impeller 7 is arranged in the volute 5, the main shaft 4 is socketed with the volute 5, The head of the volute 5 is provided with a type ring 6, the outer end of the turbine impeller 7 extends into the type ring 6, the volute 5 commun...

Embodiment 2

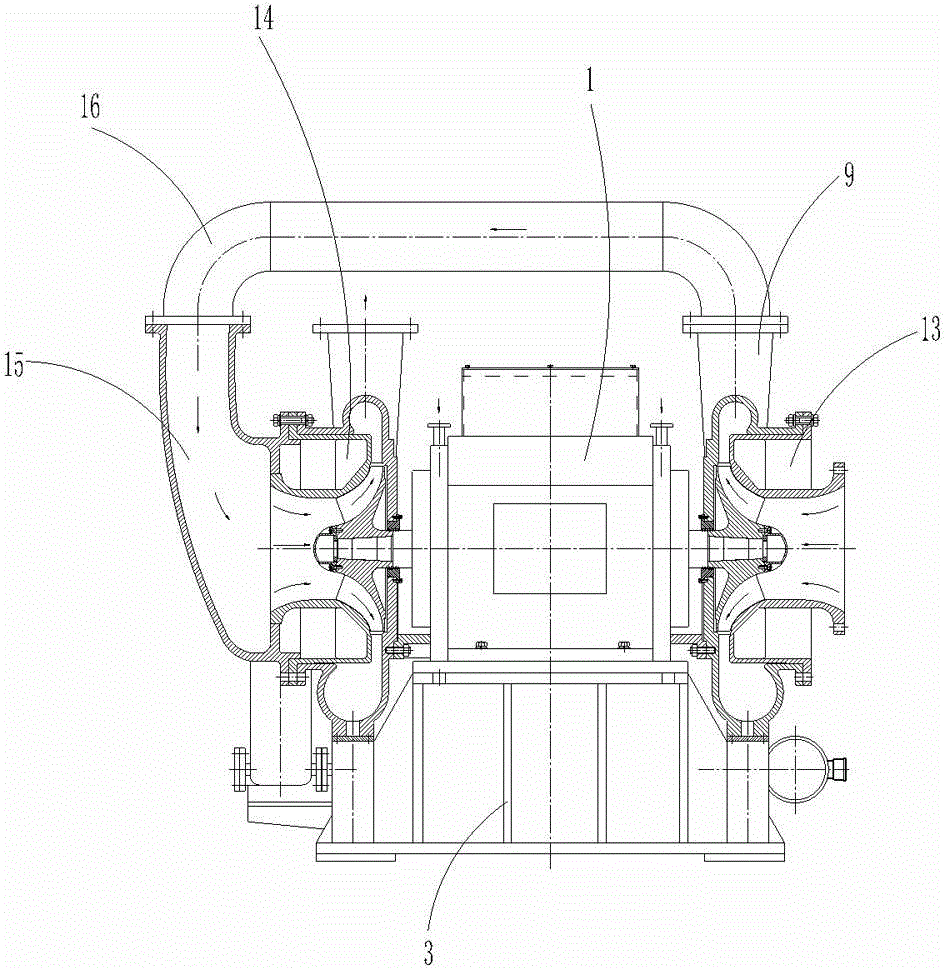

[0059] Embodiment 2: as figure 2 As shown, a direct-drive high-speed turbo vacuum pump includes a direct-connected high-speed motor 1, the direct-connected high-speed motor 1 communicates with a lubricating oil station 2, and the direct-connected high-speed motor 1 is arranged on a platform 3, The direct-coupled high-speed motor 1 is provided with a main shaft 4;

[0060] The left side end of described direct-coupled high-speed motor 1 is provided with left impeller mechanism 13, and the right side end of described direct-coupled high-speed motor 1 is provided with right impeller mechanism 14, and described left impeller mechanism 13 and right impeller mechanism 14 They are respectively arranged at the two ends of the main shaft 4, the structures of the left impeller mechanism 13, the right impeller mechanism 14 and the impeller mechanism are the same, and the outer end of the middle-shaped ring of the left impeller mechanism 13 communicates with the diversion chamber 15, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com