Hot gas flow dissociation dewatering indirect Karl-Fischer-process analysis device

An analysis device, Karl Fischer's technology, applied in the field of analysis devices, can solve the problems of inability to detect viscous samples, etc., and achieve the effects of reducing emissions, accurate measurement, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

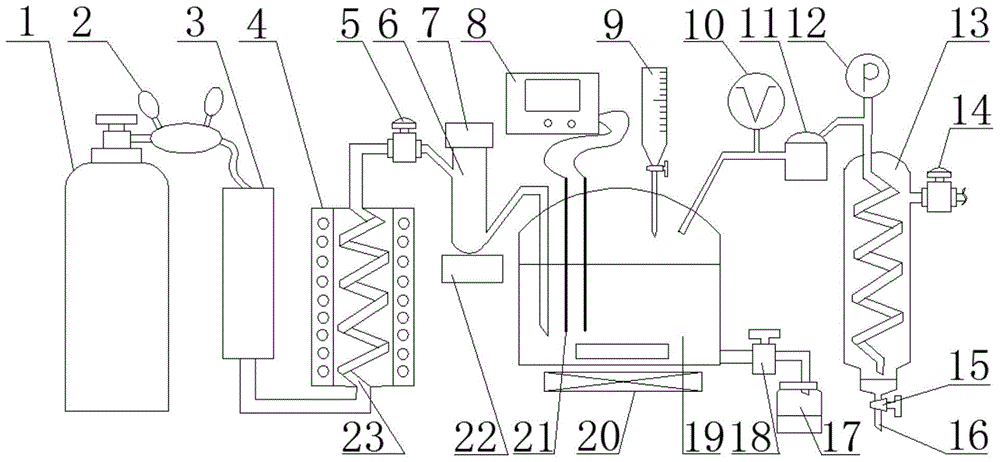

[0037] An indirect Karl Fischer method analysis device for dissociation and dehydration of hot gas flow, its structure is as follows figure 1 Shown, comprise the Karl Fischer titration assembly that is made up of titration tank 19, Karl Fischer burette 9, electrode 21, coulometer 8, electromagnetic stirrer 20 below titration tank 19, waste liquid bottle 17, by miniature air pump 11 and The methanol recovery component composed of the methanol condenser 13 also includes a gas heating component arranged outside the titration cell 19 , which releases moisture after heating the sample, and the moisture is brought into the titration cell 19 by the hot gas flow. The gas heating assembly includes a nitrogen cylinder 1, a molecular sieve dehydrator 3, a gas heating coil 23 and a sampling device 6 connected in sequence. Heating plate 22.

[0038] The molecular sieve dehydrator 3 is connected to the nitrogen cylinder 1 through a hose to remove trace moisture in the nitrogen gas. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com