Substrate transferring method for power semiconductor device with perpendicular structure

A technology for power semiconductor and substrate transfer, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of short circuit, inability to manufacture vertical structure devices, device failure, etc., achieving low consumption and easy implementation , to ensure the effectiveness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

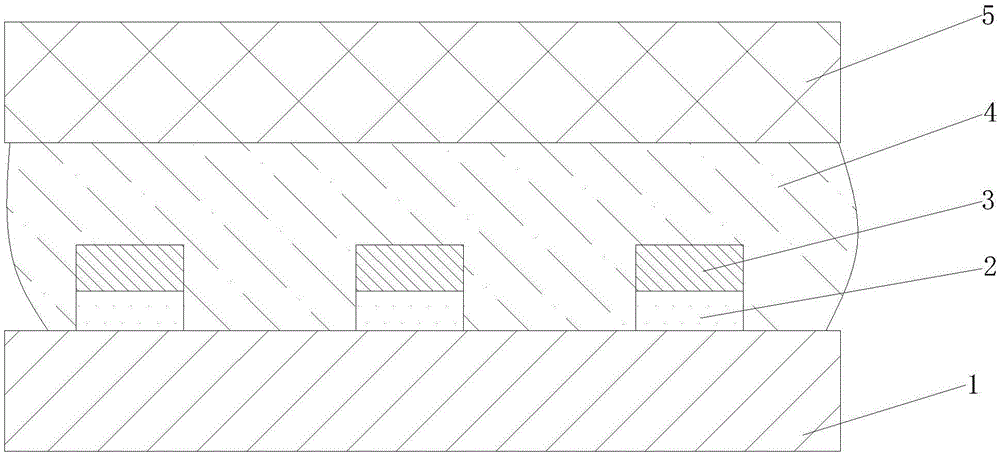

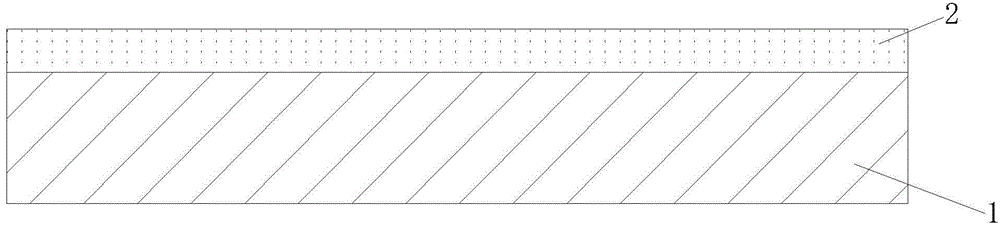

[0028] see Figure 2-9 As shown, a substrate transfer method for a vertical structure power semiconductor device, the power semiconductor device arranged on the sapphire substrate 1 is transferred to the target substrate 5, and the power semiconductor device includes epitaxial growth on the sapphire substrate 1 Layer 2 and a plurality of metal electrode blocks 3 that are plated on the upper surface of the epitaxial layer 2 at intervals, the substrate transfer method mainly includes the following steps:

[0029] 1) Place solder 4: place solder 4 as a bonding material on the upper surface of the metal electrode block of the power semiconductor device, the projected area of the solder 4 on the horizontal plane is smaller than the projected area of the metal electrode block 3 on the horizontal plane;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com