An additive type energy storage membrane and a preparing method thereof

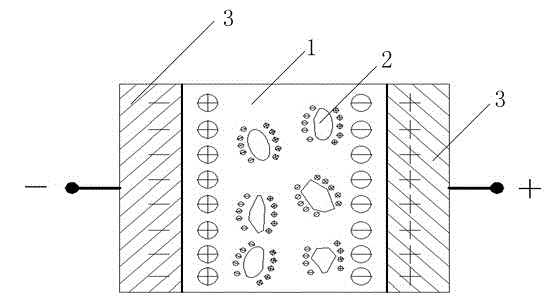

An energy storage film and additive technology, which can be used in the manufacture of hybrid/electric double layer capacitors, electrolytic capacitors, electrical components, etc. It can solve the problems of limiting the output of stored charge, high internal resistance, and affecting the storage performance of the energy storage film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

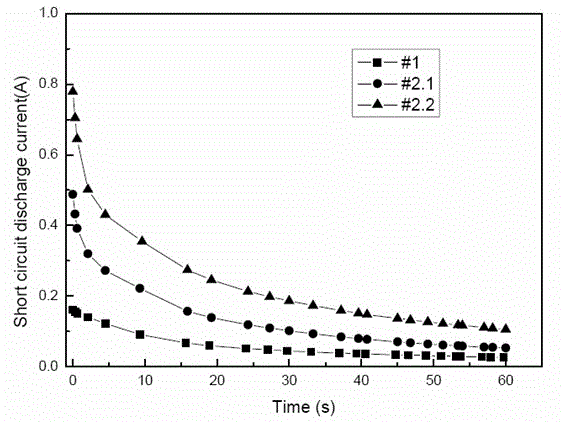

[0038] Samples #2.1-#2.2 and a set of reference samples #1 were respectively prepared according to the method of the present invention (that is, no conductive particles were added, and the reference samples in other embodiments were also #1). The reference sample is an energy storage film without adding any conductive particles. The size of the energy storage film used is 7.0cm×7.0cm, the thickness is 1.0mm, and the weight is 10g. The electrode material used is flake graphite paper, and the doped conductive particles are graphite particles with an average particle size of 0.2 mm. The mass ratios of graphite powder in samples #2.1-2.2 are 5.0% and 15.0%, respectively.

[0039] Use the YOKOGAWA GS610 signal source measurement unit to measure the energy storage performance of samples #2.1-2.2 and reference sample #1 respectively. After charging for 2 minutes, as figure 2 As shown, the final obtained results are shown in Table 1:

[0040] Table 1

[0041]

[0042] As the amo...

Embodiment 2

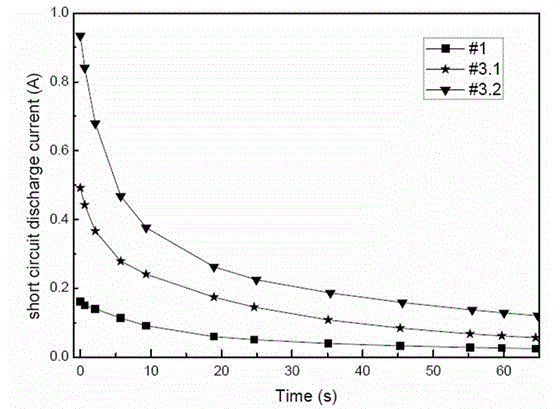

[0044] Samples #3.1-#3.2 and a set of reference sample #1 (ie no conductive particles added) were prepared according to the method of the present invention. The reference sample is an energy storage film without adding any conductive particles. The size of the energy storage film used is 7.0cm×7.0cm, the thickness is 1.0mm, and the weight is 10g. The electrode material used is flake graphite paper, and the doped conductive particles are graphite particles with an average particle size of 0.2 mm. The mass ratio of graphite doping in samples #3.1-3.2 is 15.0%, and the selected graphite-containing particles average The particle sizes are 0.3mm and 0.15mm respectively.

[0045] Doped with the same mass ratio of graphite particles, the electrical storage performance of the sample increases with the decrease of the average particle size, and the highest average particle size is 0.15 mm. When the particle size is further reduced, the power storage performance begins to decline.

[...

Embodiment 3

[0051] Samples #4.1-4.2 were prepared respectively according to the method of the present invention, and the used energy storage films all had a size of 7.0cm×7.0cm, a thickness of 1.0mm, and a weight of 10g. The electrode material used is flake graphite paper, the doped conductive particles are copper powder and the average particle size distribution is 0.9, 0.15mm, and the corresponding mass ratios are 1.0% and 9.0%, respectively, as shown in Table 3.1:

[0052] chart 3.1

[0053]

[0054] Use the YOKOGAWA GS610 signal source measurement unit to measure the energy storage performance of samples #4.1-4.2 and the reference sample respectively. After charging for 2 minutes, as image 3 As shown, the final obtained results are shown in Table 3.2: Table 3.2

[0055]

[0056] After doping aluminum powder, the peak short-circuit current is about 1-3 times higher than that of the reference sample. As the particle size of the copper particles used becomes smaller, the effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com