Preparation method of micro-miniature direct formic acid fuel cell based on mems technology

A formic acid fuel cell, micro-miniature technology, applied in fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of large overall size, complex structure, poor corrosion resistance, etc., to overcome corrosion and simplify the battery. Structure, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

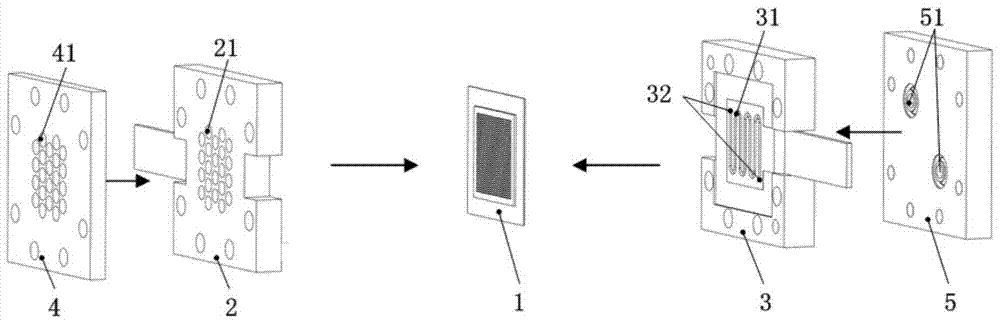

[0026] see figure 1 , the structure of the micro-miniature direct formic acid fuel cell prepared in the present embodiment, comprising membrane electrode (MEA) 1, electrode-bearing PDMS flow field plate 2 with air channel 21, serpentine micro-flow channel 31 and inlet and outlet liquid The anode PDMS flow field plate 3 with an electrode channel 32, the aluminum cathode pressure plate 4 with an air channel 41, and the aluminum anode pressure plate 5 with a liquid inlet and outlet channel 51 are assembled together by bolting.

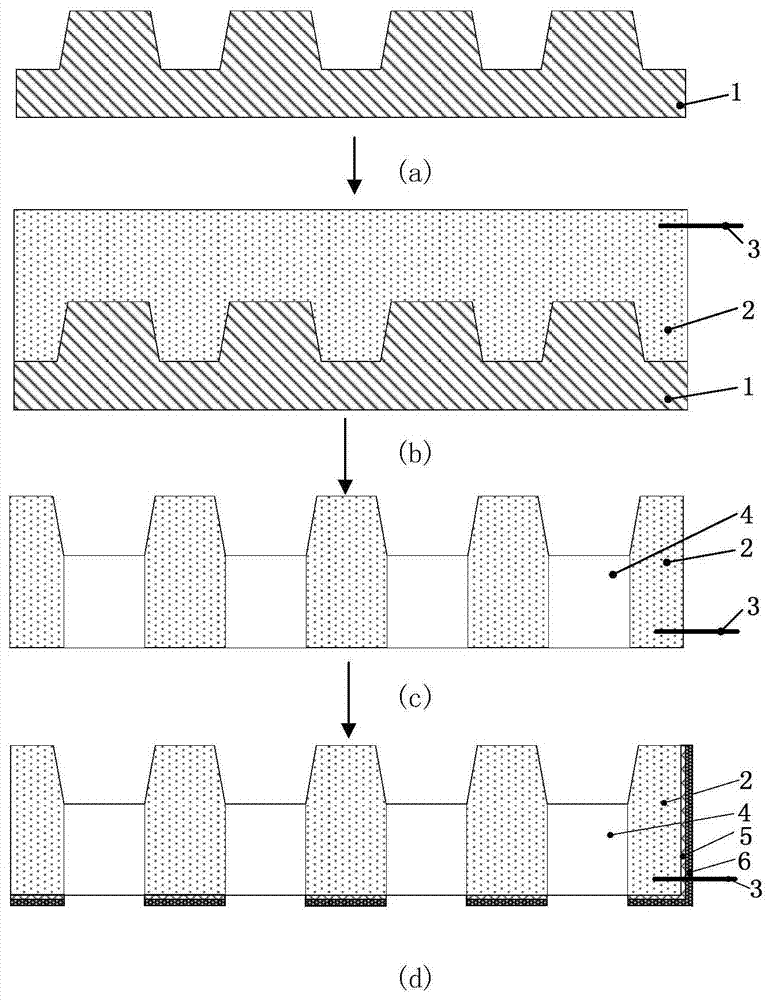

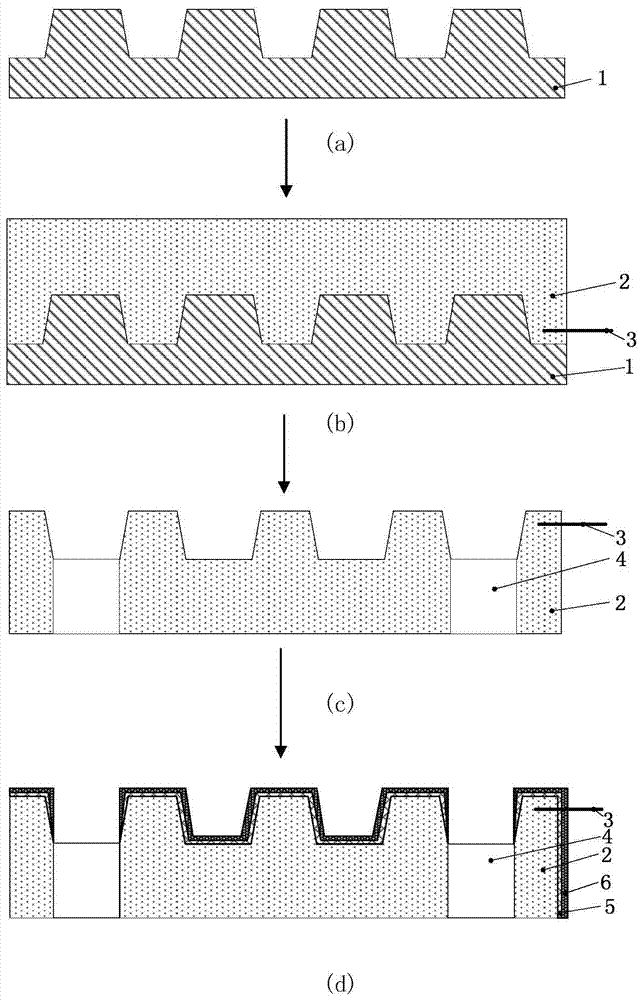

[0027] see figure 2 , Preparation of PDMS flow field plate with electrode cathode: (a) using oxidation, photolithography and anisotropic wet etching micromachining technology to fabricate a square boss array 1 with a boss size of 1600 μm × 1600 μm on a silicon wafer; (b) Put the silicon wafer into the cavity of the mold, spray the release agent and PDMS glue 2 (PDMS substrate: PDMS curing agent = 10:1), and embed the copper foil electrode 3 to cure afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com