Process for preparing tilmicosin pellets

A technology of tilmicosin and pellets, which is applied in the field of preparation of tilmicosin pellets, can solve the problems of incompleteness and inability to use laying hens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

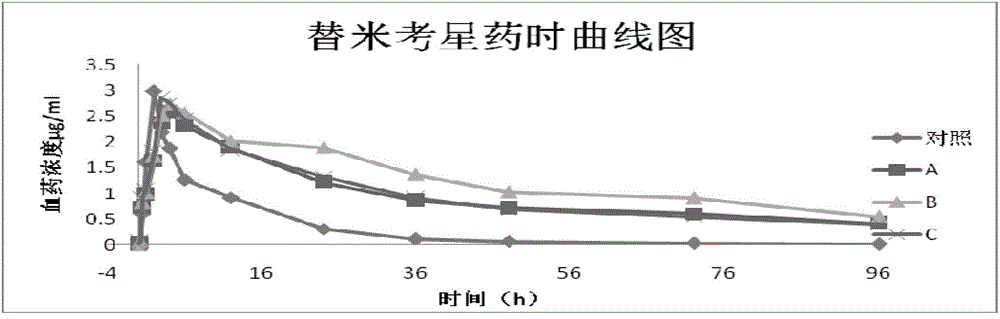

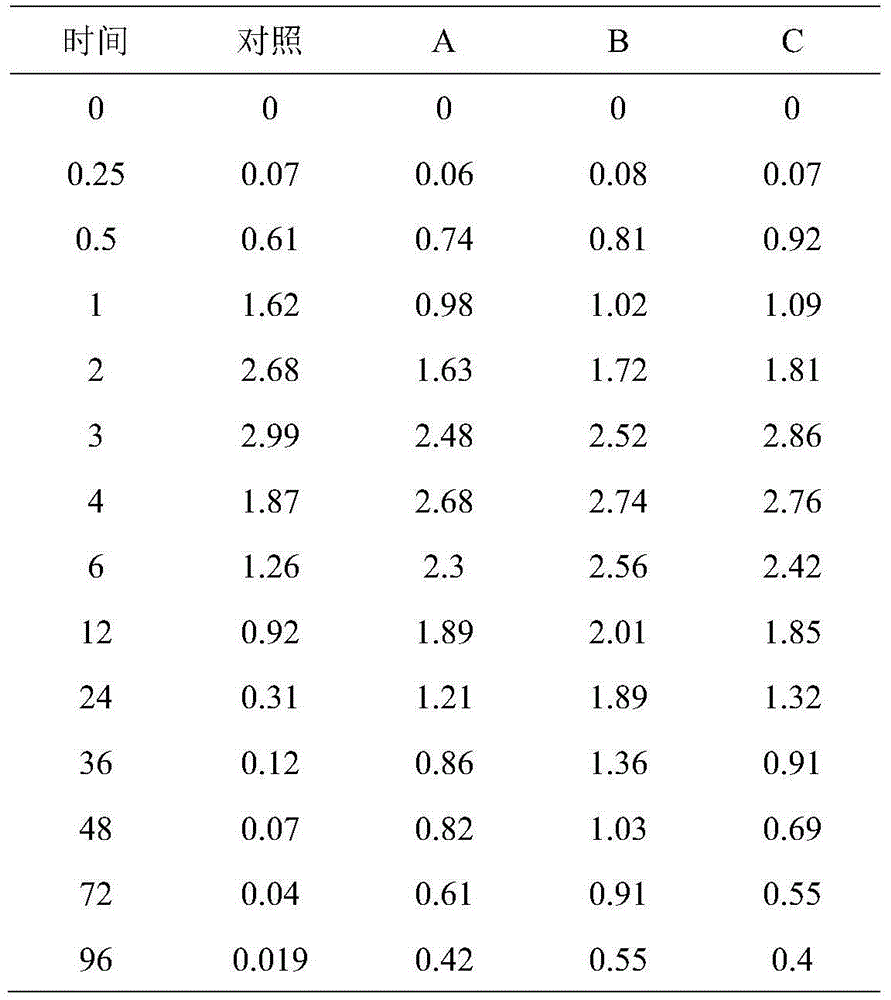

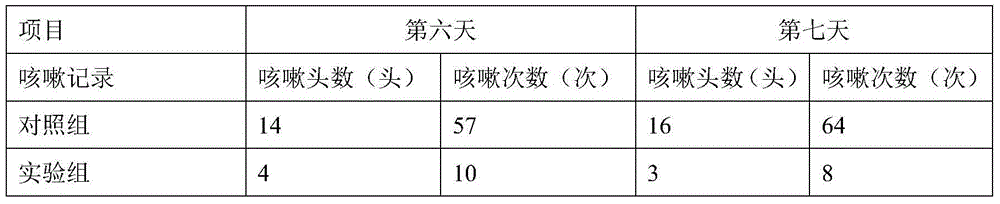

Image

Examples

Embodiment 1

[0018] Embodiment 1 The preparation method of tilmicosin pellets of the present invention

[0019] 1 Mix tilmicosin with an appropriate amount of microcrystalline cellulose (MCC) and low-substituted hypromellose (L-HPC) evenly, add an appropriate amount of diluted ethanol to moisten, pass through a 30-mesh sieve, and place the particles in a spheronizer Sphericalized and dried at 50°C, the skeleton-type sustained-release pellets I were obtained; the content of tilmicosin was 40%, and the ratio of MCC to L-HPC was 19:1. Among them, microcrystalline cellulose can also be sucrose or starch; low-substituted hypromellose (L-HPC) can also be hydroxypropyl cellulose (HPMC) or other skeleton materials, but this scheme is preferred.

[0020] 2 Dissolve an appropriate amount of povidone K90 (PVPK90) and carbomer in an appropriate amount of 80% ethanol solution, add tilmicosin and stir continuously to form a uniform suspension, add the ball core to the fluidized bed turntable, and The a...

Embodiment 2

[0022] Embodiment 2 The preparation method of tilmicosin pellets of the present invention

[0023] 1 Mix tilmicosin with an appropriate amount of microcrystalline cellulose (MCC) and low-substituted hypromellose (L-HPC) evenly, add an appropriate amount of diluted ethanol to moisten, pass through a 30-mesh sieve, and place the particles in a spheronizer Sphericalized and dried at 50°C, the skeleton-type sustained-release pellets I were obtained; the content of tilmicosin was 60%, and the ratio of MCC to L-HPC was 4:1. Among them, microcrystalline cellulose can also be sucrose or starch; low-substituted hypromellose (L-HPC) can also be hydroxypropyl cellulose (HPMC) or other skeleton materials, but this scheme is preferred.

[0024] 2 Dissolve an appropriate amount of povidone K90 (PVPK90) and carbomer in an appropriate amount of 80% ethanol solution, add tilmicosin and stir continuously to form a uniform suspension, add the ball core to the fluidized bed turntable, and The ab...

Embodiment 3

[0026] Embodiment 3 The preparation method of tilmicosin pellets of the present invention

[0027] 1 Mix tilmicosin with an appropriate amount of microcrystalline cellulose (MCC) and low-substituted hypromellose (L-HPC) evenly, add an appropriate amount of diluted ethanol to moisten, pass through a 30-mesh sieve, and place the particles in a spheronizer Sphericalized and dried at 50°C, the skeleton-type sustained-release pellets I were obtained; the content of tilmicosin was 50%, and the ratio of MCC to L-HPC was 10:1. Among them, microcrystalline cellulose can also be sucrose or starch; low-substituted hypromellose (L-HPC) can also be hydroxypropyl cellulose (HPMC) or other skeleton materials, but this scheme is preferred.

[0028] 2 Dissolve an appropriate amount of povidone K90 (PVPK90) and carbomer in an appropriate amount of 80% ethanol solution, add tilmicosin and stir continuously to form a uniform suspension, add the ball core to the fluidized bed turntable, and The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com