A kind of levetiracetam sustained-release tablet and preparation method thereof

A technology for sustained-release tablets and tablet cores, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. and other problems, to achieve the effect of simple product prescription, simple preparation process and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

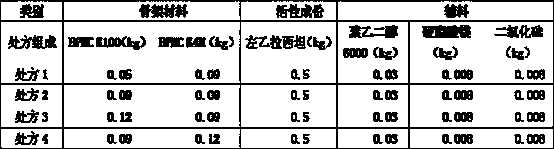

[0020] Table 1 Prescriptions using two different framework materials

[0021]

[0022] Preparation:

[0023] (1) Granulation: Weigh the prescribed amount of levetiracetam, add 25g of low-viscosity hypromellose (HPMC E50) 3% w / w aqueous solution to make soft material, granulate with 20 mesh sieve, boil and dry, 10 Mesh sieving;

[0024] The parameters of boiling drying are: fan power: 30-50Hz; back-blowing interval: 3-20 seconds; inlet air temperature: 40-60°C; material temperature: 30-40°C, measure the moisture of the mixture, and control the moisture at 0.5-1.5%;

[0025] (2) Mixing: Weigh the prescribed amount of levetiracetam particles, framework material, and glidant and mix for 15-20 minutes, then add lubricant and mix for 2-3 minutes;

[0026] (3) Tablet compression: The mixed materials are compressed into tablet cores with a tablet hardness of 13-15kg;

[0027] (4) Preparation of coating solution: Disperse 20g of Opadry 295F in 113g of water and stir for 40-50 minutes to prepare ...

Embodiment 2

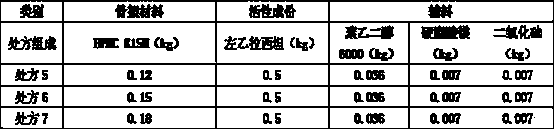

[0031] Table 2 Formulations using a single skeleton material

[0032]

[0033] Preparation:

[0034] (1) Granulation: Weigh the prescribed amount of levetiracetam, add 25g of low-viscosity hypromellose (HPMC E50) 3% w / w aqueous solution to make soft material, granulate with 30 mesh sieve, boil and dry, 20 Mesh sieving;

[0035] The parameters of boiling drying are: fan power: 30-50Hz; back-blowing interval: 3-20 seconds; inlet air temperature: 40-60°C; material temperature: 30-40°C, measure the moisture of the mixture, and control the moisture at 0.5-1.5%;

[0036] (2) Mixing: Weigh the prescribed amount of levetiracetam particles, framework material, and glidant and mix for 15-20 minutes, then add lubricant and mix for 2-3 minutes;

[0037] (3) Tablet compression: The mixed materials are compressed into tablet cores with a tablet hardness of 13-15kg;

[0038] (4) Preparation of coating solution: Disperse 22g of Opadry 295F in 115g of water and stir for 40-50 minutes to prepare a 16% co...

Embodiment 3

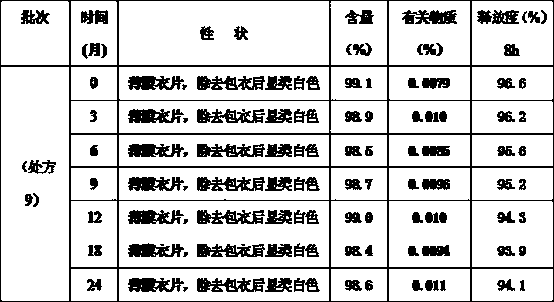

[0041] Table 3 Prescriptions using different amounts of lubricant

[0042]

[0043] Preparation:

[0044] (1) Granulation: Weigh the prescribed amount of levetiracetam, add 25g of low-viscosity hypromellose (HPMC E50) 3% w / w aqueous solution to make soft material, granulate with 20 mesh sieve, boil and dry, 20 Mesh sieving;

[0045] The parameters of boiling drying are: fan power: 30-50Hz; back-blowing interval: 3-20 seconds; inlet air temperature: 40-60°C; material temperature: 30-40°C, measure the moisture of the mixture, and control the moisture at 0.5-1.5%;

[0046] (2) Mixing: Weigh the prescribed amount of levetiracetam particles, framework material, and glidant and mix for 15-20 minutes, then add lubricant and mix for 2-3 minutes;

[0047] (3) Tablet compression: The mixed materials are compressed into tablet cores with a tablet hardness of 13-15kg;

[0048] (4) Preparation of coating solution: Disperse 20g of Opadry 295F in 91g of water and stir for 40-50 minutes to prepare an 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com