VOC decomposition composite-purifying processing apparatus and method

A composite purification and treatment device technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of low investment costs and achieve the effects of less investment, lower operating costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

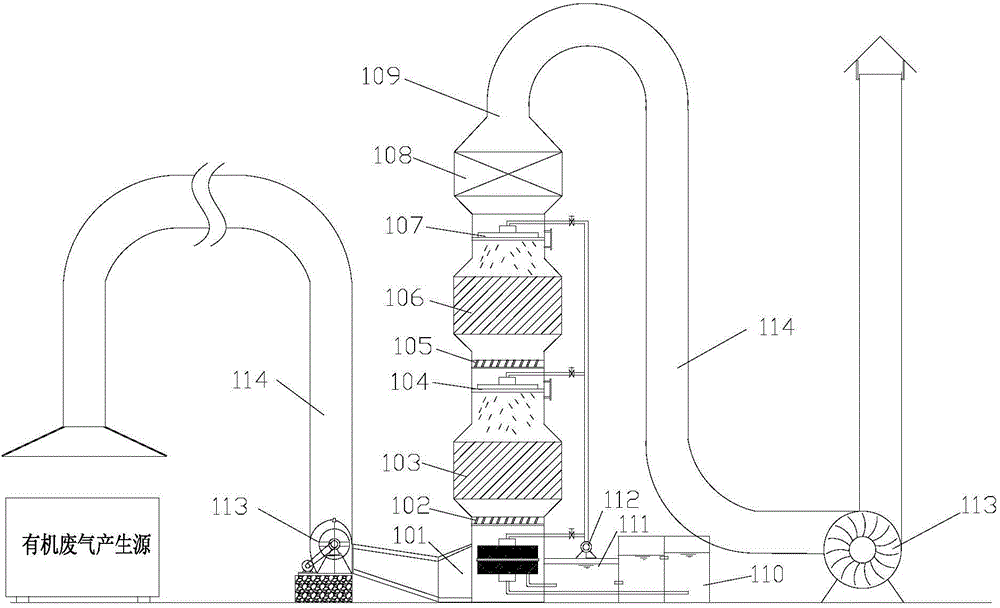

[0066] The VOC decomposition composite purification treatment device includes a tower body, a circulating pool 111, and a composite decomposition pool 110. The interior of the tower body is sequentially provided with an air inlet, a first liquid collector, a first packing layer, and a first liquid A distributor, a second liquid collector, a second packing layer, a second liquid distributor, an ultraviolet light tube, a gas-liquid separator and an air outlet; the filler adopts fiber ball filler.

[0067] Liquid A and liquid B of the spray liquid are mixed in a mass ratio of 8:5.

[0068] The composition of A liquid, by weight percentage, comprises the following components:

[0069] Sodium citrate 7%, sodium acetate 9%, sodium dodecylbenzenesulfonate 3%, water 81%.

[0070] The composition of liquid B, in terms of weight percentage, includes the following components:

[0071] Ferric chloride 2%, EDTA 3%, protein degrading enzyme 10%, water 85%.

[0072] The VOC decomposition ...

Embodiment 2

[0080] The VOC decomposition composite purification treatment device includes a tower body, a circulating pool 111, and a composite decomposition pool 110. The interior of the tower body is sequentially provided with an air inlet, a first liquid collector, a first packing layer, and a first liquid A distributor, a second liquid collector, a second packing layer, a second liquid distributor, an ultraviolet light tube, a gas-liquid separator and an air outlet; the filler adopts fiber ball filler.

[0081] Liquid A and liquid B of the spray liquid are mixed in a mass ratio of 7:4.

[0082] The composition of A liquid, by weight percentage, comprises the following components:

[0083] Sodium citrate 9%, sodium acetate 7%, sodium dodecylbenzenesulfonate 5%, water 79%.

[0084] The composition of liquid B, in terms of weight percentage, includes the following components:

[0085] Ferric chloride 4%, EDTA 1%, protein degrading enzyme 18%, water 77%.

[0086] The VOC decomposition co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com