Fast smoke desulfurizing tower

A desulfurization tower, fast technology, applied in the field of flue gas purification, can solve the problems of uneven contact area, easy corrosion desulfurization tower, poor desulfurization effect, etc., to solve the problem of insufficient contact, improve speed and effect, and prevent splashing everywhere Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

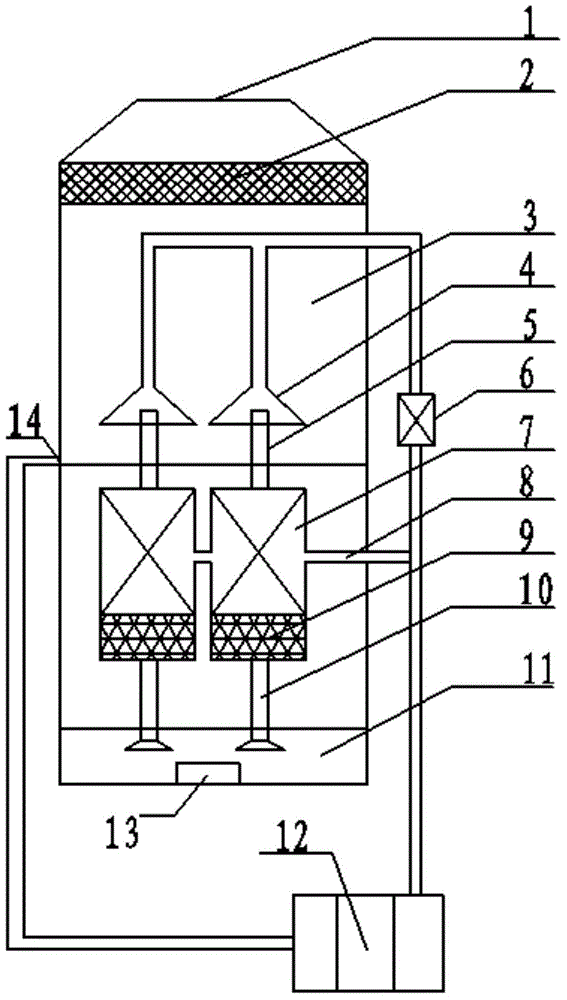

[0029] Such as figure 1 As shown, a flue gas fast desulfurization tower includes:

[0030] The outlet layer is arranged on the top of the desulfurization tower; the outlet layer includes an outlet 1 and a demister layer 2, and the desulfurized flue gas has a lot of moisture and vaporized sulfide, and these moisture and sulfide are in the The droplets are gathered on the demister layer 2 and finally drip into the buffer layer 3 .

[0031] Gas-liquid hedge layer 3, which is arranged below the outlet layer and communicates with the outlet layer, at least one vertically downward shoot tube is arranged inside the hedge layer, and the lower end opening of the shoot tube is set as an inverted funnel 4. The hydraulic pump 6 extracts the desulfurization liquid from the desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com