A kind of aluminum alloy profile and its manufacturing method

A technology for aluminum alloy profiles and manufacturing methods, applied in chemical instruments and methods, metal layered products, electrophoretic plating, etc., to achieve the effects of improving corrosion resistance, UV resistance, and stable and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

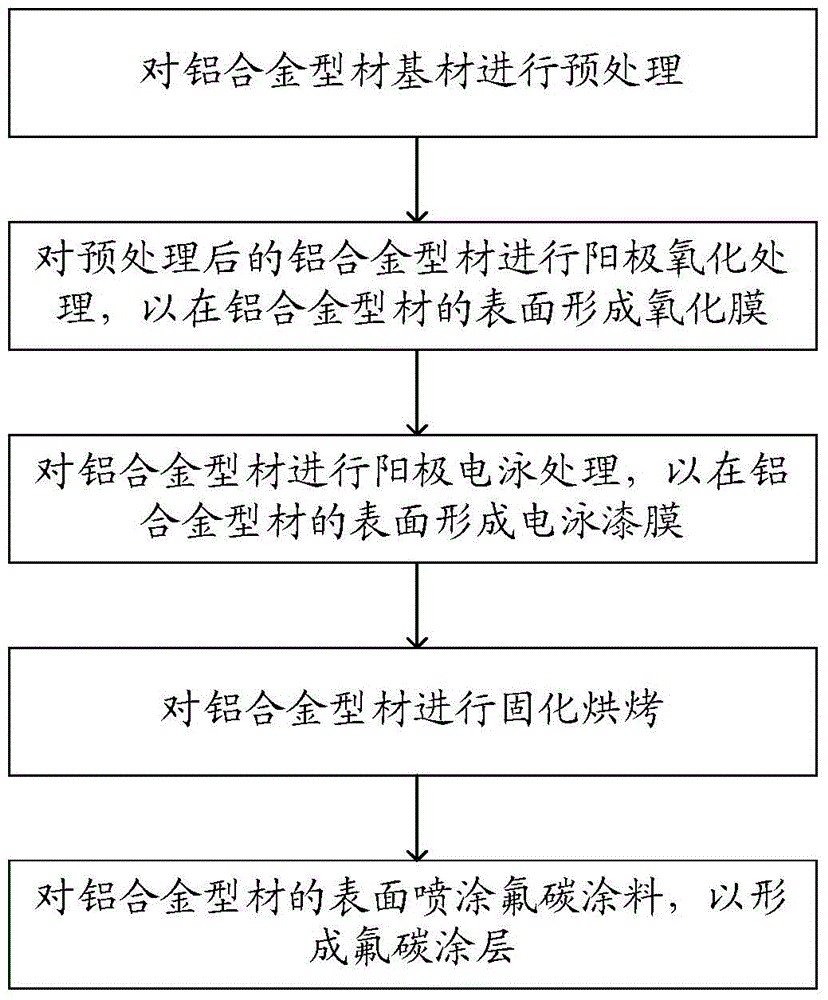

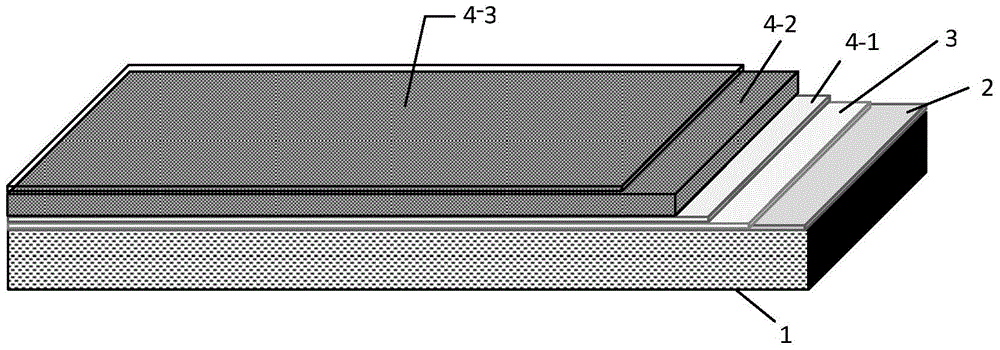

Method used

Image

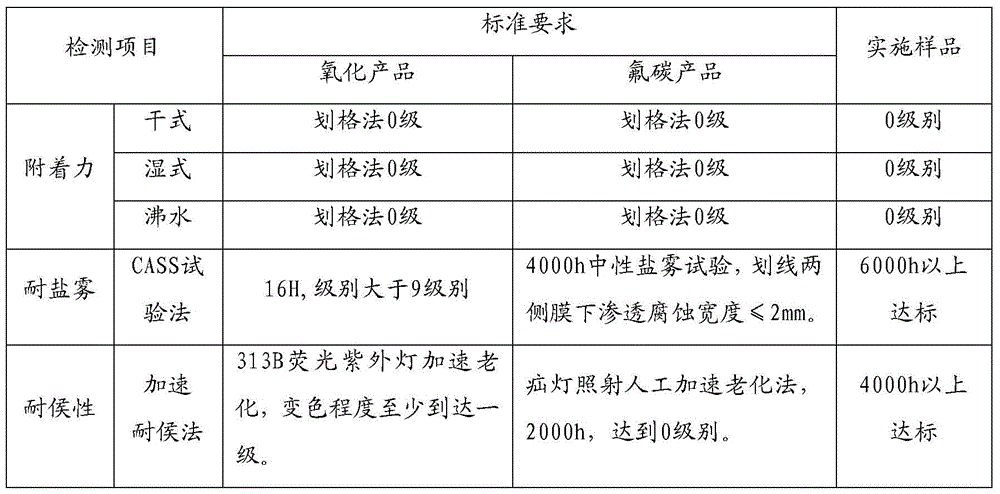

Examples

Embodiment 1

[0072] 1. Aluminum profile substrate: Take a section of 6063 alloy 100mm*25mm*2mm (wall thickness) square tube profile that meets the requirements of the national standard (GB 5237, 1-2008);

[0073] 2. Degreasing pretreatment: Use the acid degreasing agent of Pude Chemical to make a degreasing solution with a weight ratio of 5%, soak the profile in the solution for 5 minutes, and visually clean the oil on the surface of the profile and take it out;

[0074] 3. Washing;

[0075] 4. Alkali corrosion: Soak in a solution with a concentration of sodium hydroxide of 52g / L and a temperature of 64°C for 4 minutes;

[0076] 5. Washing;

[0077] 6. Neutralization: soak for 3 minutes in a solution with a sulfuric acid concentration of 185g / L;

[0078] 7. Washing;

[0079] 8. Anodizing:

[0080] 8.1. Put the profile into a solution with a sulfuric acid concentration of 165g / L, use the aluminum profile as the anode, and the pure aluminum plate as the cathode, and connect to direct cur...

Embodiment 2

[0098] 1. Aluminum profile base material: take a section of 6063 alloy 100mm*25mm*2mm (wall thickness) square tube profile that meets the requirements of the national standard (GB 5237,1-2008);

[0099] 2. Degreasing pretreatment: Use the acid degreasing agent of Pude Chemical to make a 4% degreasing solution by weight, soak the profile in the solution for 10 minutes, and visually clean the oil on the surface of the profile and take it out;

[0100] 3. Washing;

[0101] 4. Alkali corrosion: Soak in a solution with a concentration of sodium hydroxide of 40g / L and a temperature of 70°C for 3 minutes;

[0102] 5. Washing;

[0103] 6. Neutralization: Soak in a solution with a sulfuric acid concentration of 220g / L for 2 minutes;

[0104] 7. Washing;

[0105] 8. Anodizing:

[0106] 8.1. Put the profile into a solution with a sulfuric acid concentration of 180g / L, use the aluminum profile as the anode, and the pure aluminum plate as the cathode, and connect to direct current;

[0...

Embodiment 3

[0124] 1. Aluminum profile base material: take a section of 6063 alloy 100mm*25mm*2mm (wall thickness) square tube profile that meets the requirements of the national standard (GB 5237,1-2008);

[0125] 2. Degreasing pretreatment: use the acid degreasing agent of Pude Chemical to make a 10% degreasing solution by weight, soak the profile in the solution for 8 minutes, and clean the oil stain on the surface of the profile to remove it;

[0126] 3. Washing;

[0127] 4. Alkali corrosion: Soak in a solution with a concentration of sodium hydroxide of 60g / L and a temperature of 60°C for 5 minutes;

[0128] 5. Washing;

[0129] 6. Neutralization: soak for 4 minutes in a solution with a sulfuric acid concentration of 160g / L;

[0130] 7. Washing;

[0131] 8. Anodizing:

[0132] 8.1. Put the profile into a solution with a sulfuric acid concentration of 150g / L, use the aluminum profile as the anode, and the pure aluminum plate as the cathode, and connect to direct current;

[0133]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com