Method of preparing white carbon black by virtue of carbonization method

A white carbon black and carbonization technology, applied in the directions of silicon oxide, silicon dioxide, etc., can solve the problems of large consumption of carbon dioxide, inability to continuous production, long reaction time, etc., and achieve continuous reaction efficiency, fast reaction speed and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

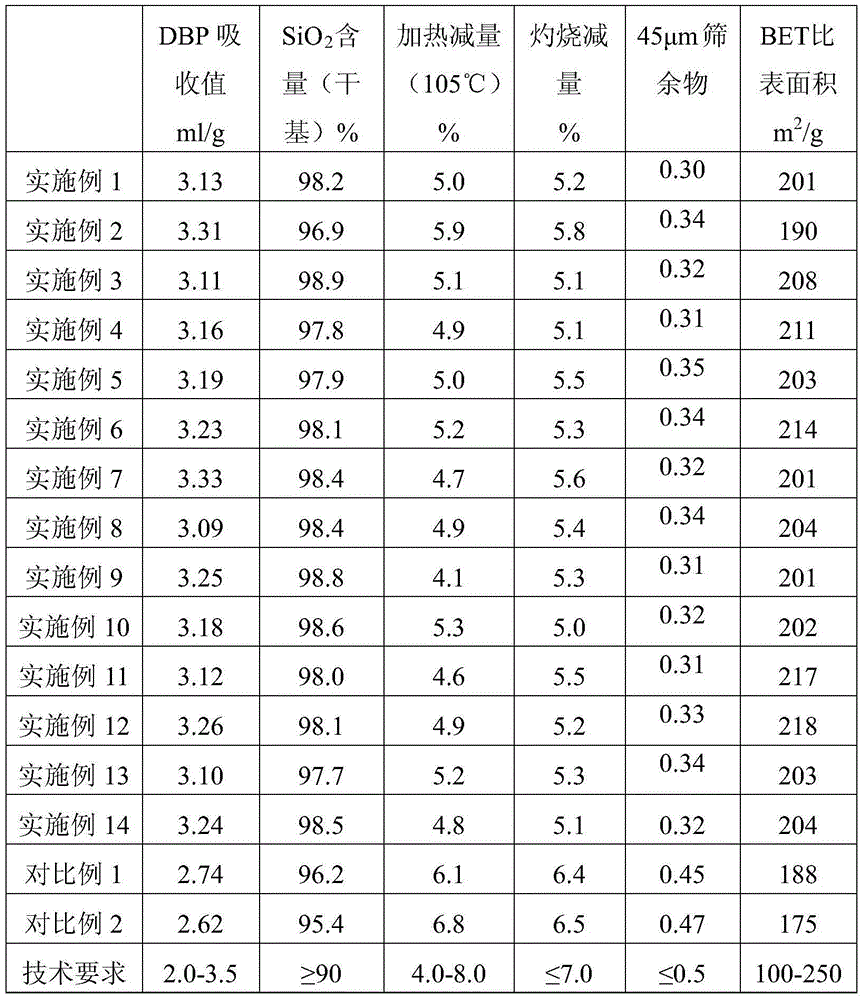

Examples

Embodiment 1

[0022] The liquid water glass with a modulus of 2.5 is mixed with water to prepare 10 kg of water glass solution with a mass fraction of 25%. After stirring evenly under heating at 75°C, it is passed into a high-pressure spray reaction tower. The particle size is 5 microns, the pressure inside the control tower is 0.8Mpa, the pressure is kept stable by supplementing pure carbon dioxide gas, the waste gas is discharged in time, and the carbon dioxide content in the tower is kept at 60% (other components are water vapor), and the temperature inside the tower is controlled at 90°C. Continuous production, the silica slurry settled at the bottom of the reaction tower is transported to the storage tank through pipelines to obtain the silica slurry, after washing and refining, the finished silica is obtained by spray drying, and the silica performance is tested.

Embodiment 2

[0024] The liquid water glass with a modulus of 3.8 is mixed with water to make 10 kg of water glass solution with a mass fraction of 5%, and after being stirred evenly under heating at 40°C, it is passed into a high-pressure spray reaction tower, and the rotational speed of the atomizing disc and the amount of feed are controlled such that The atomization particle size is 100 microns, the pressure inside the control tower is 0.05Mpa, the pressure is kept stable by supplementing pure carbon dioxide gas, the waste gas is discharged in time, and the carbon dioxide content in the tower is kept at 100%, the temperature inside the tower is controlled at 40°C, continuous production, reaction tower The bottom-settled silica slurry is transported to the storage tank through pipelines to obtain the silica slurry. After washing and refining, flash drying is used to obtain the finished silica, and the silica performance test is carried out.

Embodiment 3

[0026] Add water to the liquid water glass with a modulus of 2.8 to prepare 10 kg of water glass solution with a mass fraction of 15%, add 50 g of sodium carbonate, stir evenly under heating at 55°C, and then pass it into the high-pressure spray reaction tower, and control the rotation speed of the atomizing disc And the feeding amount makes the atomized particle size be 20 microns, the pressure inside the control tower is 0.5Mpa, supplement the mixed gas containing 60% carbon dioxide (other components are air) to keep the pressure stable, discharge waste gas in time, and keep the carbon dioxide content in the tower at 80% % (other components are air and water vapor), the temperature in the tower is controlled at 70 ° C, continuous production, the sedimentation silica slurry at the bottom of the reaction tower is transported to the storage tank through pipelines, and the silica slurry is obtained. After washing and refining , the finished product of silica was obtained by spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com