A kind of preparation method of small grain nay type molecular sieve

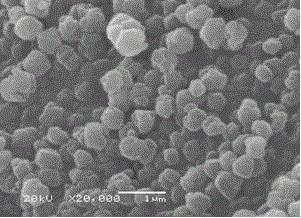

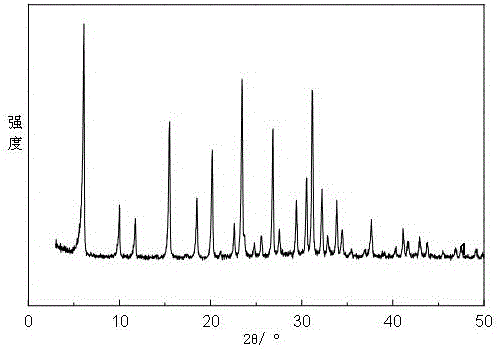

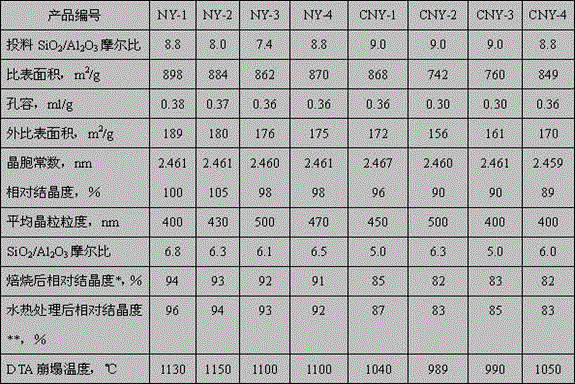

A small-grain, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problem of poor hydrothermal stability of fine-grained Y-type molecular sieve, uneven distribution of silicon and aluminum, and technical problems. Complicated steps and other problems, to achieve the effect of improving the effective utilization rate, concentrating the distribution range of grains, and uniform distribution of silicon and aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of directing agent: Dissolve 8 g of sodium hydroxide solid in 80 g of water, add 2.5 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 40g water glass (SiO 2 Content is 28wt%, Na 2 The O content is 8wt%), mixed evenly, and aged at 18° C. for 4 hours to prepare the directing agent.

[0035] (2) Preparation of amorphous silicon-aluminum precursor

[0036] Prepare solid sodium aluminate to a concentration of 0.3L for 100g A1 2 o 3 / L sodium aluminate working solution (a). Dilute the concentrated ammonia water with an appropriate amount of distilled water to obtain about 10wt% dilute ammonia water (b). SiO 2 28wt% sodium silicate solution, then diluted to 0.5L concentration is 140g SiO 2 / L sodium silicate working solution (c). Take a 5-liter steel reaction tank, add 0.5 liter of distilled water to the tank, stir and heat to 70°C, open the valves of the sulfur containers respectively (a), (b) and (c) at the sa...

Embodiment 2

[0042] (1) Preparation of guiding agent: Dissolve 10 g of sodium hydroxide solid in 90 g of water, add 3 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 50g water glass (SiO 2 Content is 28wt%, Na 2 The O content is 8wt%), mixed evenly, and aged at 20° C. for 4 hours to prepare the directing agent.

[0043] (2) Preparation of amorphous silicon-aluminum precursor

[0044] Prepare solid aluminum sulfate to a concentration of 80g A1 in 0.5L 2 o 3 / L aluminum sulfate working solution (a). Dilute the concentrated ammonia water with an appropriate amount of distilled water to obtain about 10wt% dilute ammonia water (b). SiO 2 28wt% sodium silicate solution, then diluted to 0.4L concentration is 150g SiO 2 / L sodium silicate working solution (c). Take a 5-liter steel reaction tank, add 0.5 liter of distilled water to the tank, stir and heat to 70°C, open the valves of the containers (a), (b) and (c) at the same time, control (a) and ...

Embodiment 3

[0050] (1) Preparation of the directing agent: The preparation of the directing agent is the same as in Example 1.

[0051] (2) Preparation of amorphous silicon-aluminum precursor

[0052] Prepare solid aluminum chloride to 0.5L concentration to be 100g A1 2 o 3 / L aluminum chloride working solution (a). Dilute the concentrated ammonia water with an appropriate amount of distilled water to obtain about 10wt% dilute ammonia water (b). SiO 2 28wt% sodium silicate solution, then diluted to 0.4L concentration of 125g SiO 2 / L sodium silicate working solution (c). Take a 5-liter steel reaction tank, add 0.5 liter of distilled water to the tank, stir and heat to 70°C, open the valves of the containers (a), (b) and (c) at the same time, control (a) and ( c) the flow rate to keep the neutralization reaction time at 40 minutes, and quickly adjust the flow rate of (b) to keep the pH value of the system at 7-8, and control the temperature of the system at about 60°C. After the alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com