Biochemical sludge swelling control system and control method thereof

A control system, biochemical sludge technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large killing of normal flora, insignificant regulation effect, and low operating cost and other problems, to achieve the effect of accelerating elimination, promoting cohesion, and achieving good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

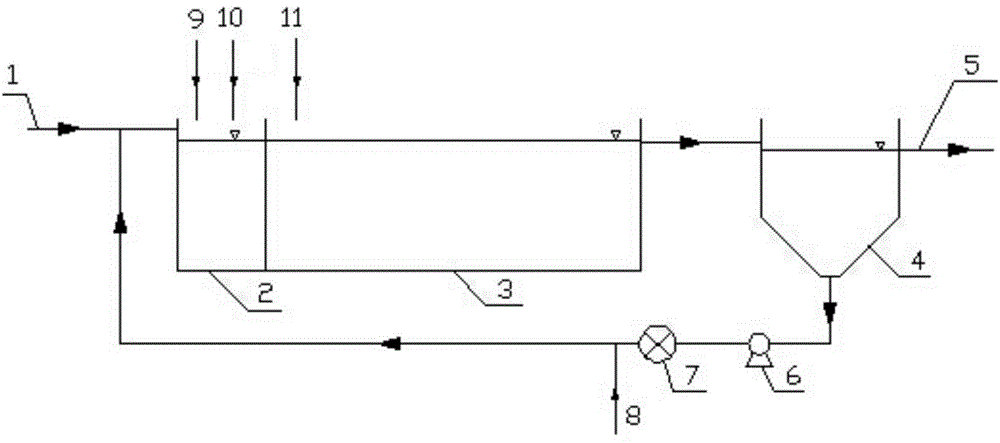

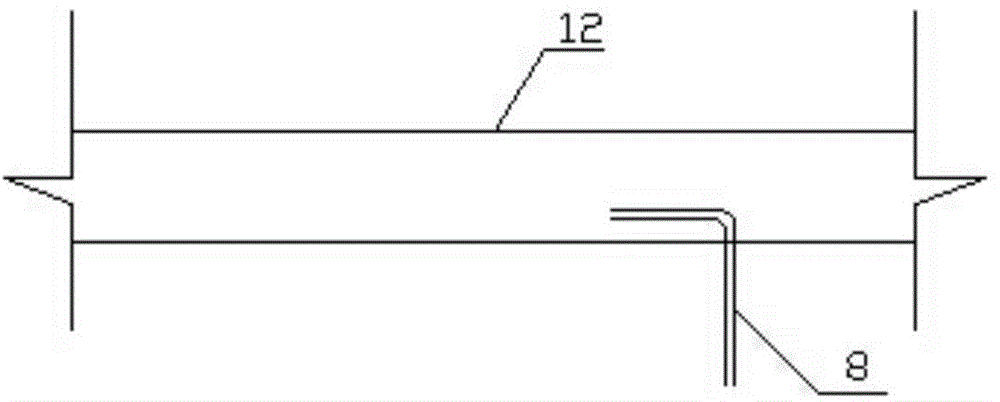

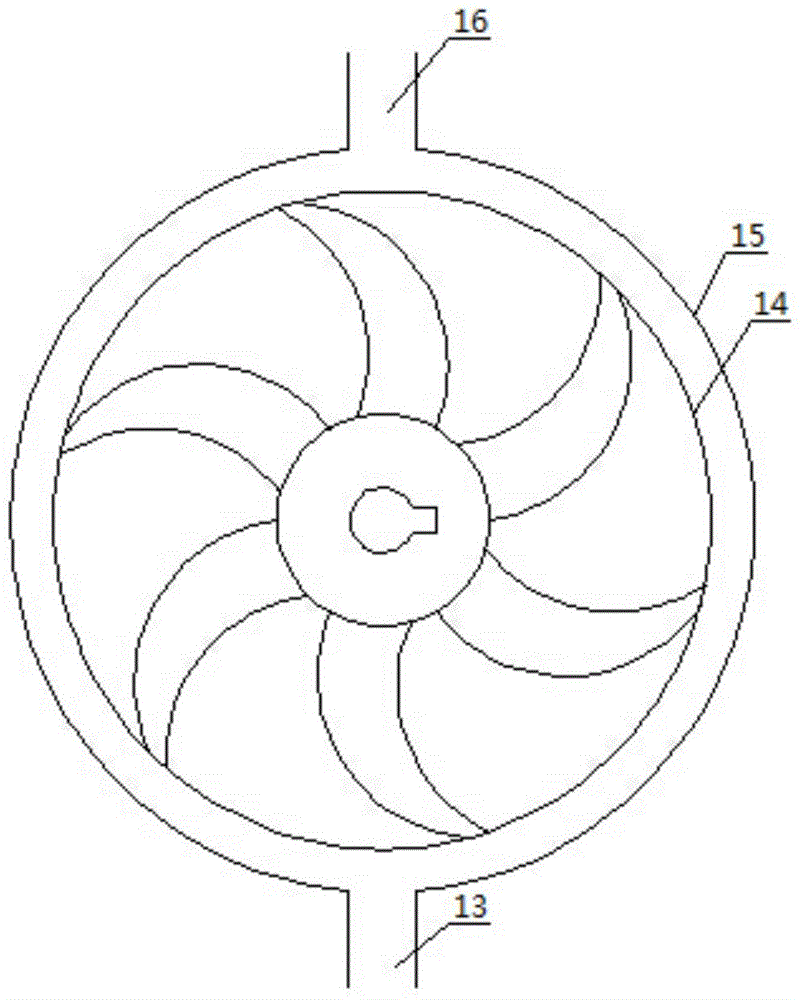

[0029] From figure 1 and figure 2 It can be seen that a biochemical sludge bulking control system in this embodiment includes a water inlet 1, a secondary settling tank 4 and a water outlet 5, and the bottom outlet of the secondary settling tank 4 is connected with a sludge return pipeline 12. Flow direction in return pipe 12, sludge return pump 6, shearer 7 and H 2 o2 The dosing pipe 8, wherein: the sludge return pump 6 is used to pump the sludge to the elutriation tank 2 along the return direction, and the shearer 7 is used to interrupt the mycelia of the filamentous fungus in the return sludge, H 2 o 2 The dosing pipe 8 is vertically connected to the sludge return pipe 12, and penetrates into the sludge return pipe 12, and is bent at 90° along the sludge return direction. The direction of the dosing port is consistent with the flow direction of the sludge. This setting can Effectively prevent the return sludge from entering the dosing pipe, which is conducive to smooth ...

Embodiment 2

[0039] A biochemical sludge bulking control system of this embodiment has the same basic structure as that of Embodiment 1.

[0040] A printing and dyeing wastewater treatment plant in Henan adopts the "grid-coagulation-sedimentation-hydrolysis acidification-biological selection-aerobic-secondary sedimentation" process, with a treatment capacity of 3,000 tons / day. Filamentous bacteria sludge often occurs, and the sludge volume index The SVI is as high as about 350ml / g, the abundance of filamentous bacteria is at the level e of the tank, the suspended solids in the effluent of the secondary sedimentation tank seriously exceed the standard (up to 500mg / L or more), and sludge is often lost.

[0041] Aiming at the specific problems existing in the printing and dyeing wastewater treatment plant, a biochemical sludge bulking control system of this embodiment is adopted. The control method of the control system includes the following steps:

[0042] Step 1: The return sludge in the s...

Embodiment 3

[0048] A biochemical sludge bulking control system of this embodiment has the same basic structure as that of Embodiment 1.

[0049]The sewage treatment plant of a printing and dyeing enterprise in Jiangsu adopts the process of "pH adjustment-coagulation sedimentation-UASB-aerobic-secondary sedimentation", the treatment capacity is 20,000 tons / day, the sludge settling performance is poor, and the sludge volume index SVI is 280ml / g Around, the abundance of filamentous bacteria is at the c-level of the pool, and the suspended solids index in the secondary sedimentation effluent is high (SS is about 100mg / L).

[0050] In view of the specific problems existing in the sewage treatment plant of the printing and dyeing enterprise, a biochemical sludge bulking control system of this embodiment is adopted. The control method of the control system has the following steps:

[0051] Step 1: The return sludge in the secondary settling tank 4 is transported into the shearer 7 through the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com