Method for preparing tert-butyl peroxyneodecanoate (BNP) through continuous flow

A new technology of tert-butyl decanoate and peroxidation, which is applied in the chemical industry, can solve the problems of insufficient active oxygen, poor quality stability and reproducibility, and uneven temperature distribution of tert-butyl peroxyneodecanoate. Low labor intensity, stable product quality and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

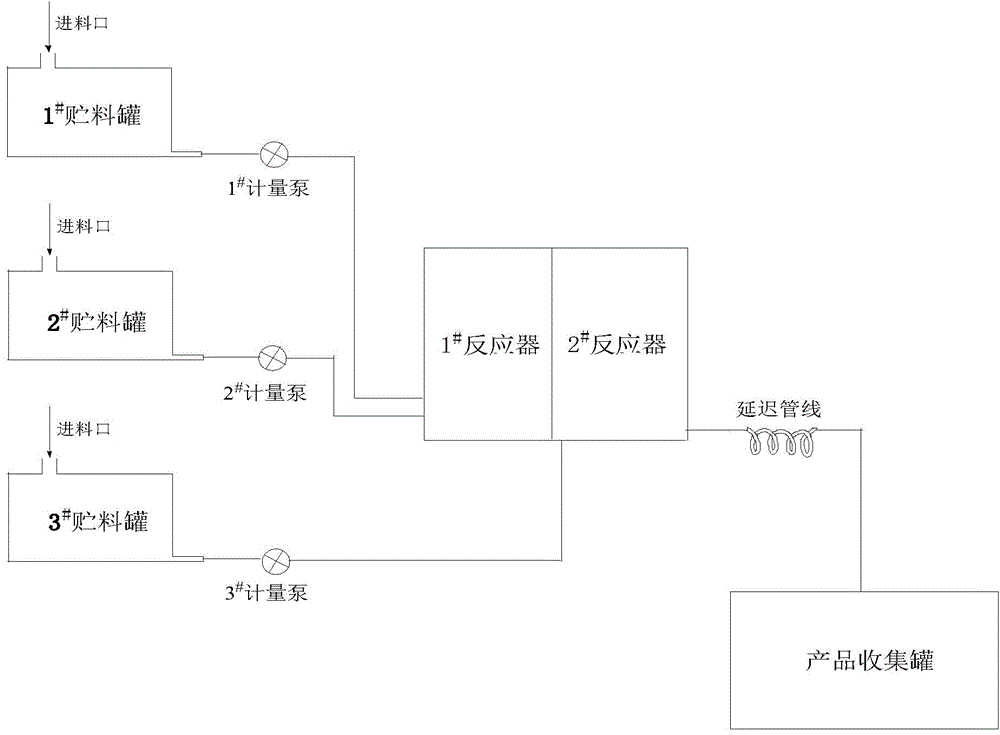

Image

Examples

Embodiment 1

[0029] (1) adding solid sodium hydroxide to deionized water to prepare a 32% sodium hydroxide aqueous solution;

[0030] (2) will 1 # The flow rate of the metering pump is set to 430ml / min, 2 # The flow rate of the metering pump is set to 120ml / min, and 1 # Metering pump, 2 # Metering pump, so that sodium hydroxide aqueous solution and tert-butyl hydroperoxide aqueous solution of 70wt% concentration enter 1 at a steady flow rate respectively # React in the reactor, add the brine of 5wt% concentration simultaneously to control reaction temperature at 10 ℃, then enter 2 # reactor;

[0031] (3) Setting 3 # The flow rate of the metering pump is 170ml / min, 3 # metering pump in 1 # Metering pump, 2 # Open after metering pump opens 50 seconds, make the neodecanoyl chloride solution of 98wt% purity enter 2 with steady flow rate # The reactor reacts with the products of sodium hydroxide aqueous solution and tert-butyl hydroperoxide aqueous solution, adding brine to control the...

Embodiment 2

[0034] (1) adding solid sodium hydroxide to deionized water to prepare a 40% aqueous sodium hydroxide solution;

[0035] (2) will 1 # The flow rate of the metering pump is set to 320ml / min, 2 # The flow rate of the metering pump is set to 80ml / min, and 1 # Metering pump, 2 # Metering pump, so that the sodium hydroxide aqueous solution and the tert-butyl hydroperoxide aqueous solution of 72wt% concentration enter 1 at a steady flow rate respectively. # React in the reactor, add the brine of 7wt% concentration simultaneously to control reaction temperature at 15 ℃, then enter 2 # reactor;

[0036] (3) Setting 3 # The flow rate of the metering pump is 150ml / min, 3 # metering pump in 1 # Metering pump, 2 # The metering pump is turned on after 70 seconds, so that the neodecanoyl chloride solution of 98wt% purity enters the 2 # The reactor reacts with the products of sodium hydroxide aqueous solution and tert-butyl hydroperoxide aqueous solution, adding brine to control the...

Embodiment 3

[0039] (1) adding solid potassium hydroxide to deionized water to prepare a 40% potassium hydroxide aqueous solution;

[0040] (2) will 1 # The flow rate of the metering pump is set to 340ml / min, 2 # The flow rate of the metering pump is set to 110ml / min, and 1 # Metering pump, 2 # Metering pump, make potassium hydroxide aqueous solution and tert-butyl hydroperoxide aqueous solution of 75wt% concentration enter 1 at a steady flow rate respectively # React in the reactor, add the brine of 10wt% concentration simultaneously to control reaction temperature at 10 ℃, then enter 2 #reactor;

[0041] (3) Setting 3 # The flow rate of the metering pump is 140ml / min, 3 # metering pump in 1 # Metering pump, 2 # After the metering pump is turned on for 40 seconds, the neodecanoyl chloride solution with a purity of 98wt% enters the 2 # The reactor reacts with the products of potassium hydroxide aqueous solution and tert-butyl hydroperoxide aqueous solution, adding brine to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com