A flame retardant type organic phase-change material and a preparing method thereof

An organic phase, flame-retardant technology, applied in the field of flame-retardant organic phase change materials and their preparation, can solve the problems affecting the application effect of phase change energy storage materials, poor heat transfer effect of paraffin wax, and limited flame retardant effect, etc. Achieve the effects of promoting large-scale use, increasing toughness, and preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

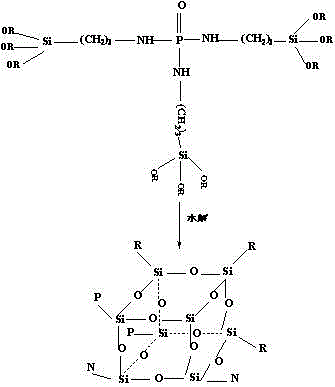

[0036] Mix absolute ethanol and triethoxysilane monomer with a mass ratio of 8:1, and add glacial acetic acid, wherein the mass ratio of the added amount of glacial acetic acid to the added amount of triethoxysilane is 1:1. Then add water dropwise under stirring at 50°C, wherein the mass ratio of water to triethoxysilane is 0.5:1, and stir until the reactant is in the form of a sol. Then add polyphosphoramide (molecular weight: 2500) to the system, the mass ratio of polyphosphoramide to triethoxysilane is 1:1, stir vigorously until the dispersion is uniform, and then dry the mixture at 100°C for 4 hours to obtain triethoxysilane Ethoxysilphosphoramide.

[0037]Take 10g of paraffin wax whose phase transition temperature and phase transition latent heat value are 58°C and 165kJ / kg respectively, and 50g of petroleum ether (boiling range is 50°C to 90°C) and mix evenly to obtain a uniformly mixed suspension. Take another glass beaker, add 10 g of triethoxysilylphosphoramide and 1...

Embodiment 2

[0040] The synthetic method of triethoxysilylphosphoramide is the same as in Example 1.

[0041] In Example 1, the quality of triethoxysilylphosphoramide and absolute ethanol was increased to 20g and 200g respectively, the addition of deionized water and ammonia water was adjusted to 40g and 80g respectively, and other operating methods and material compositions remained unchanged. A flame-retardant organic phase-change material B was obtained.

Embodiment 3

[0043] The synthetic method of triethoxysilylphosphoramide is the same as in Example 1.

[0044] In Example 1, the temperature of the water bath was kept at 75° C., and the solution containing silicon dioxide was added dropwise to the above mixed solution. Other operating methods and material compositions remained unchanged to obtain a flame-retardant organic phase change material C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com