Special photo-biological reactor system for driving microalgae cultivation by multi-stage potential energy differences

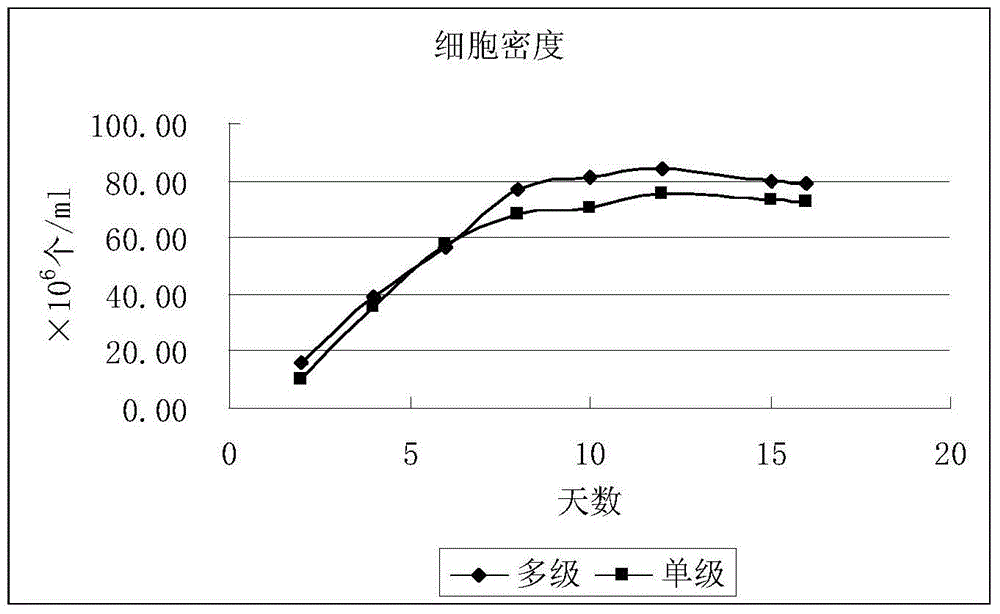

A technology for photobioreactor and microalgae cultivation, which is applied in the field of photobioreactor system dedicated to microalgae cultivation driven by multi-level potential energy difference, and can solve the problem of inability to provide conditions for microalgae growth, single light intensity and Low aeration rate, low specific growth rate of microalgae, etc., to achieve low-cost high-density culture, save energy consumption and equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The accompanying drawings show embodiments of the present invention, and the embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be construed as limiting the present invention. The scope of protection of the present invention is based on the contents of the claims. Any basis The replacement of equivalent technical means made in the specification does not depart from the protection scope of the present invention.

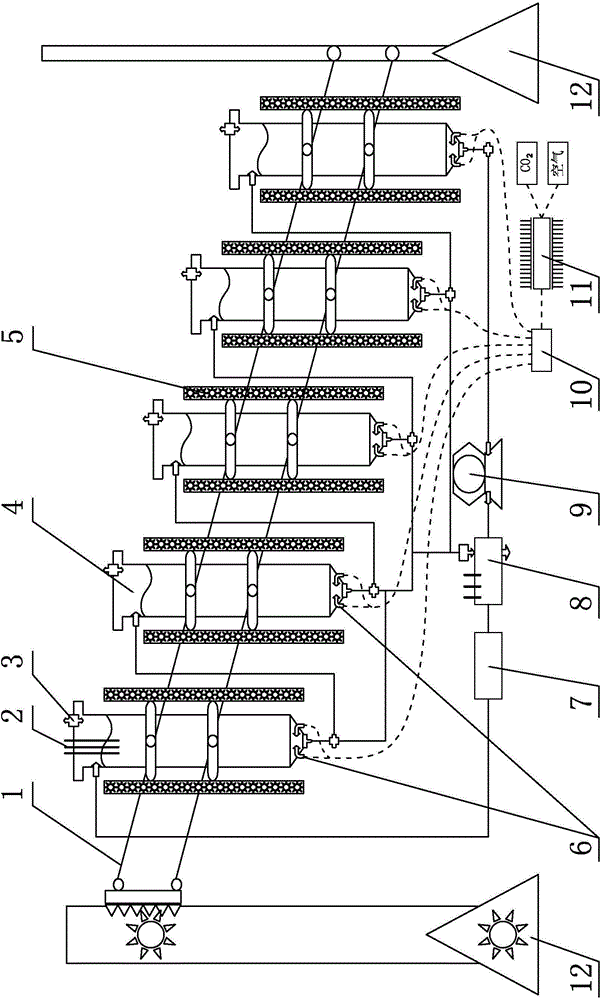

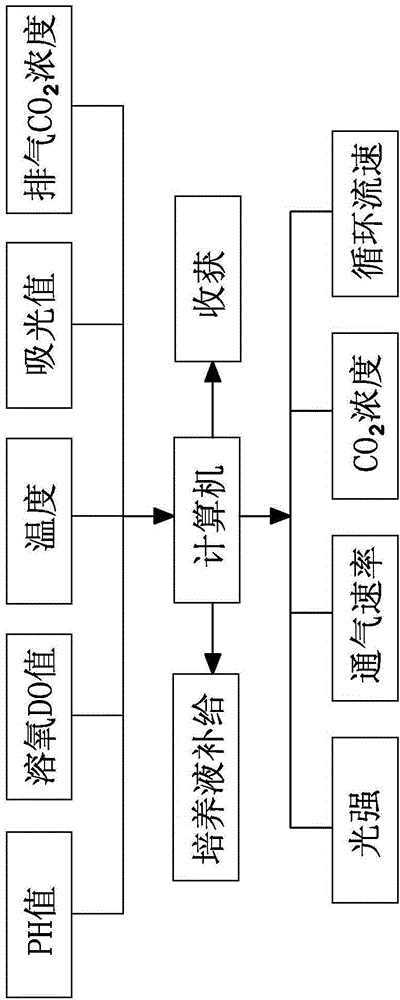

[0044] The overall technical structure of this embodiment is as shown in the figure, which includes a photoreactor, an air intake device and a circulating power source. The photoreactor is provided with an air inlet, an exhaust port, a liquid inlet and a material outlet; the system includes :

[0045] A. The photoreactor includes columnar reactors 4 that are vertically arranged and distributed at intervals, and are arranged from high to low from the beginning to the end. The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com