Manufacturing method of hetero-junction solar cell and hetero-junction solar cell

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of inability to reduce battery efficiency loss, decrease battery conversion efficiency, increase battery series resistance, etc., and achieve improved Photoelectric conversion efficiency and the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

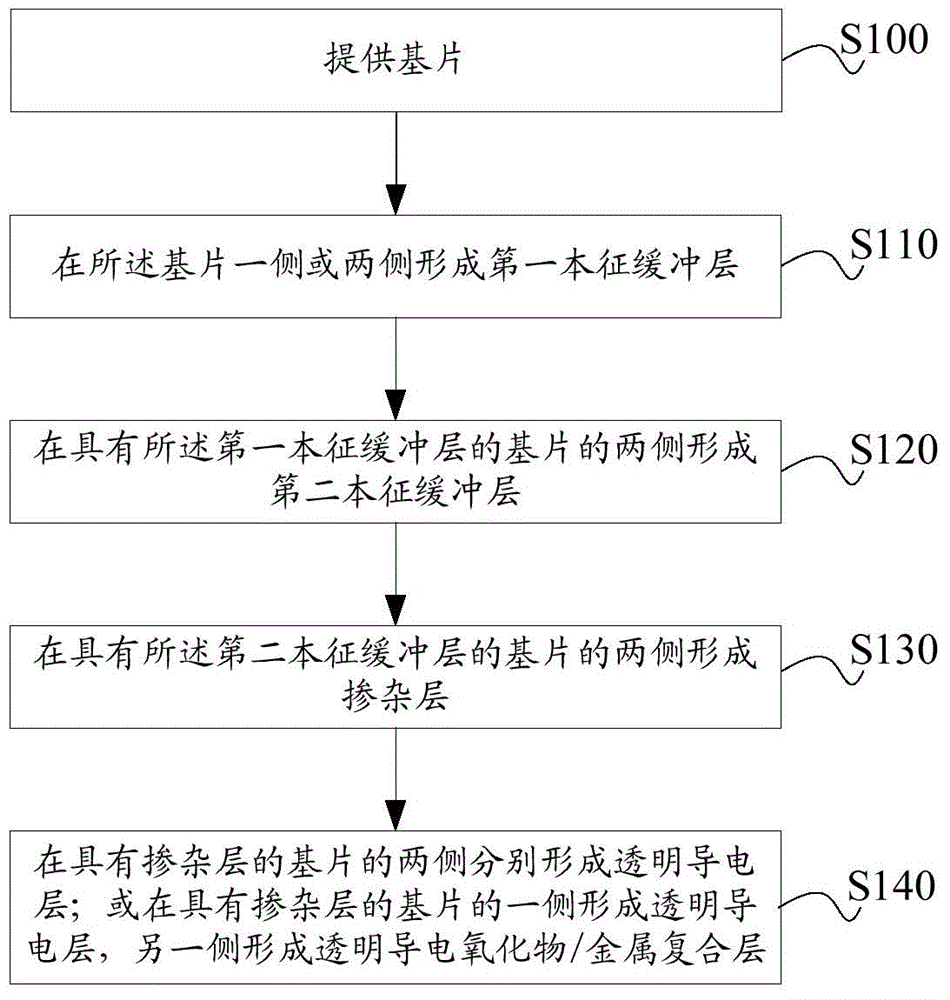

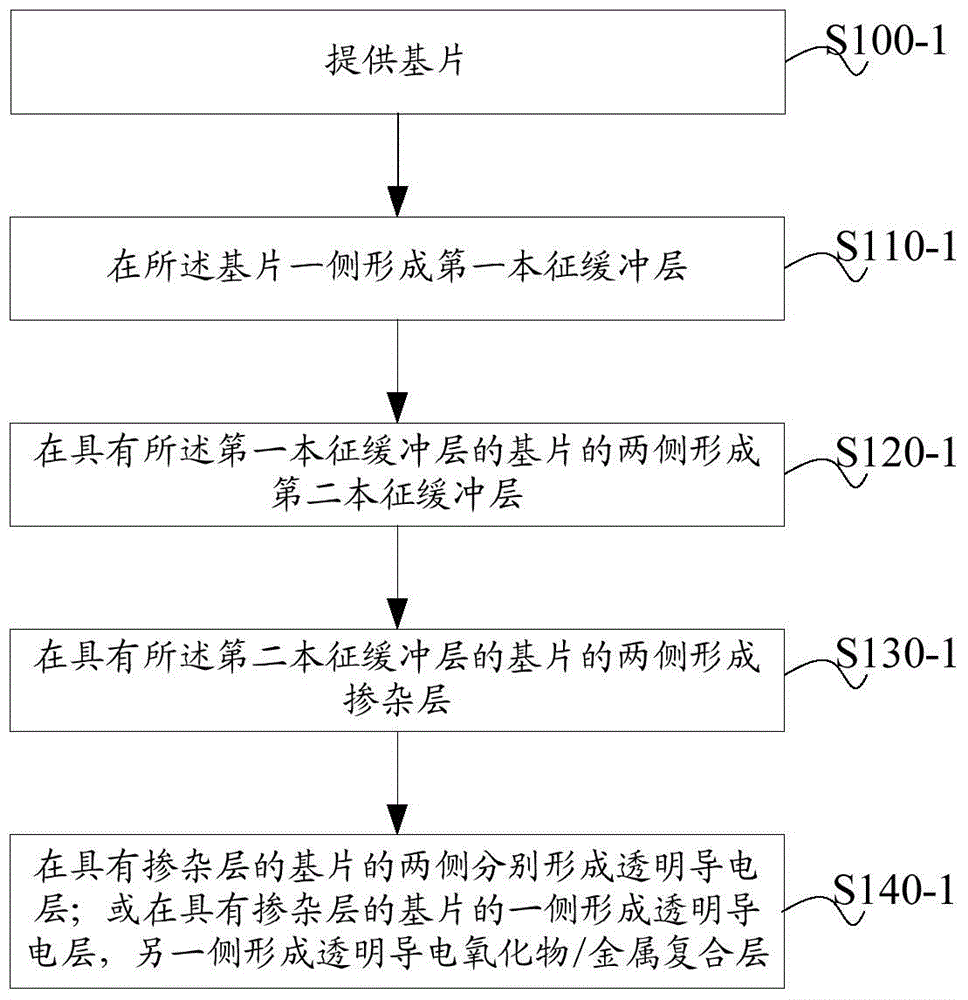

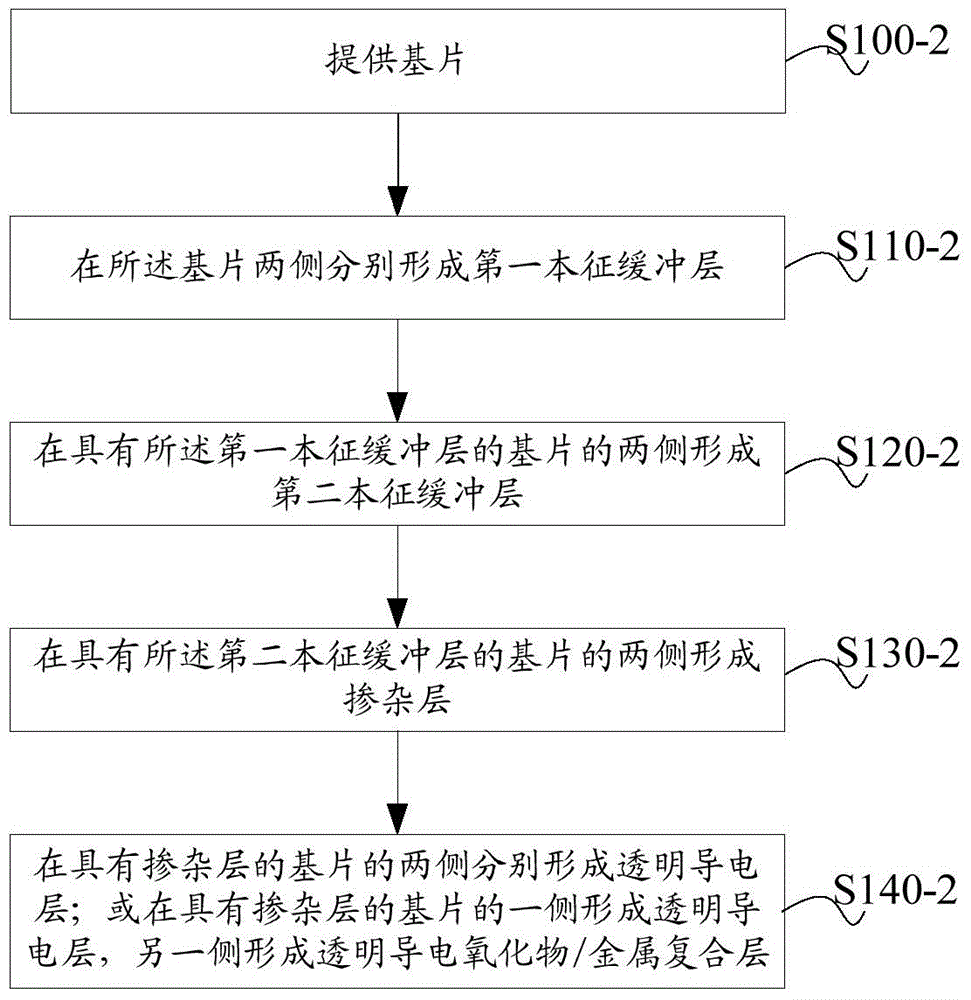

[0039] Please refer to figure 2 as shown, figure 2 It is a flow chart of the first embodiment of a method for manufacturing a heterojunction solar cell provided by the present application; this embodiment specifically includes the following steps:

[0040] Step S100-1: providing a substrate;

[0041] The substrate is made of a crystalline silicon material, which can be a monocrystalline silicon body or a polycrystalline silicon body. In this embodiment, an N-type monocrystalline silicon wafer can be selected, and its thickness range is greater than or equal to 150um and less than or equal to 300um, preferably It is 180um and the resistivity is 3Ωcm. For silicon wafers, it needs to be textured and cleaned first. The purpose of texturing is to reduce the reflection of the battery surface so that more photons can be absorbed by the substrate. Usually, the surface of silicon wafers is treated into a pyramid shape. The shape is more conducive to the oblique incidence of light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com