A kind of preparation method of carbon fiber cloth loaded sulfur composite material

A carbon fiber cloth and composite material technology is applied in the field of preparation of carbon fiber cloth-supported sulfur composite materials, which can solve problems such as affecting battery performance and damage to the internal structure of the positive electrode, and achieve the effects of stable cycle performance, improved electrochemical performance, and reduced process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

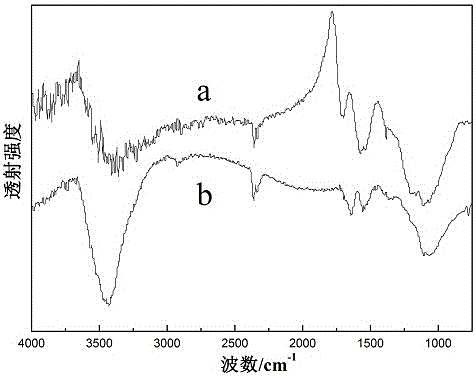

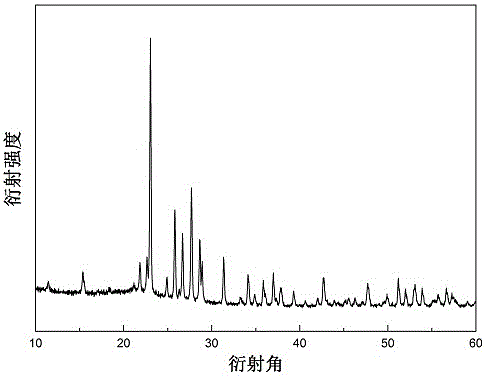

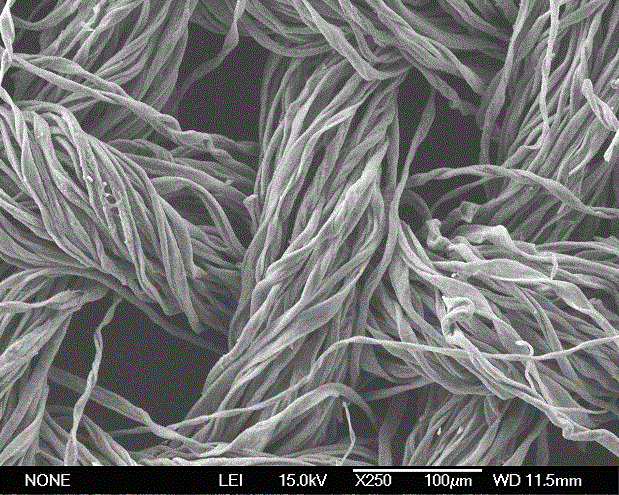

[0027] Preparation of Carbon Fiber Cloth Loaded Sulfur Composite

[0028] The steps of preparation method are as follows:

[0029] 1) Functionalization of carbon fiber cloth: Take 2×2cm cotton fiber cloth, soak it in sodium hydroxide solution in a water bath at 80°C for 5h, dry it, place it in a tube furnace, and heat it at 200°C for 3h in an argon atmosphere, then raise the temperature After heat treatment at 850°C for 2 hours, a carbonized fiber cloth was obtained; the fibers were placed in concentrated nitric acid and boiled for 8 hours under reflux to obtain a functionalized conductive carbon fiber cloth;

[0030] 2) Loading nano-sulfur particles by hydrothermal method: put the carbon fiber cloth in step (a) in the prepared deionized water / ethanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:7, and move into In a 100mL reactor, a composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained a...

Embodiment 2

[0035] 1) Functionalization of carbon fiber cloth: take 2×2cm cotton fiber cloth, soak it in sodium hydroxide solution in a water bath at 80°C for 10 hours, dry it and place it in a tube furnace, heat-treat it at 200°C for 10 hours in an argon atmosphere, and then heat it up After heat treatment at 1000°C for 2 hours, a carbonized fiber cloth was obtained; the fibers were placed in perchloric acid and boiled for 2 hours under reflux to obtain a functionalized conductive carbon fiber cloth;

[0036]2) Loading nano-sulfur particles by hydrothermal method: put the carbon fiber cloth in step (a) in the prepared ethanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:5, and move it into a 100mL reaction kettle , after hydrothermal reaction at 100℃ for 48h, the composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained.

Embodiment 3

[0038] 1) Functionalization of carbon fiber cloth: take a 2×2cm cotton fiber cloth, soak it in potassium hydroxide solution in a water bath at 80°C for 5 hours, dry it and place it in a tube furnace, heat-treat it at 300°C for 1 hour in a nitrogen atmosphere, and then heat it up to Carbonized fiber cloth was obtained after heat treatment at 750°C for 2 hours; the fibers were arranged in concentrated sulfuric acid and refluxed and boiled for 10 hours to obtain functionalized conductive carbon fiber cloth;

[0039] 2) Loading nano-sulfur particles by hydrothermal method: put the carbon fiber cloth in step (a) in the prepared water / isopropanol / sublimed sulfur / carbon disulfide solution system, the mass ratio of carbon fiber cloth: sulfur is 1:1, and move into In a 100mL reactor, a composite material of carbon fiber cloth loaded with nano-sulfur particles was obtained after a hydrothermal reaction at 150°C for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com