Functional copper foil based on graphene and preparation method thereof

A technology of graphene and copper foil, applied in the direction of electrode carrier/collector, electrical components, battery electrodes, etc., can solve the problems of battery drum shell, explosion, short circuit, etc., achieve improved safety, simple preparation method, and improved conductivity and the effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

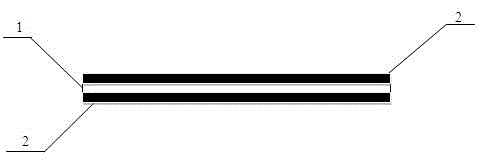

Image

Examples

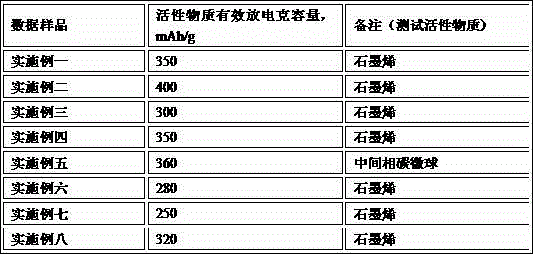

Embodiment 1

[0022] (1) Weigh graphene, conductive carbon black, and pvdf according to the weight ratio of 80:10:10, disperse in NMP at 30°C for 4 hours, and set aside;

[0023] (2) Scrape-coat the dispersed slurry of (1) on the surface of copper foil, and dry at 90°C.

[0024]

Embodiment 2

[0026] (1) Weigh graphene, carbon nanotubes, conductive carbon black, and pvdf according to the weight ratio of 70:10:10:10, and disperse them in NMP at 50°C for 2 hours before use;

[0027] (2) Scrape-coat the dispersed slurry in (1) on the surface of copper foil, and dry at 100°C.

[0028]

Embodiment 3

[0030] (1) Weigh graphene, carbon nanotubes, conductive carbon black, and pvdf according to the weight ratio of 70:10:10:10, and disperse them in NMP at 40°C for 5 hours before use;

[0031] (2) Roll the dispersed paste (1) onto the surface of the copper foil and dry it at 100°C.

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com