Adsorbing-growing aqueous phase heavy metal adsorbing material and preparation method and application thereof

A technology for adsorbing materials and heavy metals, applied in the field of environment and materials, can solve problems such as oyster shell waste pollution and secondary pollution, and achieve the effects of strong market competitiveness, improved quality, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

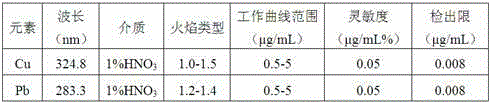

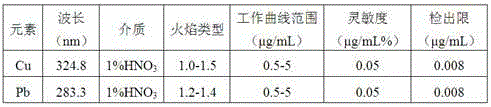

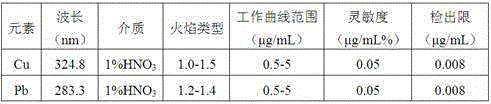

Image

Examples

preparation example Construction

[0022] The specific steps of the preparation method of the adsorption-growth water phase heavy metal adsorption material prepared by utilizing aluminum plant sludge, silicon micropowder, oyster shell and graphite powder are as follows:

[0023] (1) The sludge from the aluminum plant and the oyster shell powder sieved by the ball mill were put into a high-temperature box furnace for pre-calcination. The calcination temperature was 900 °C, the holding time was 1 h, and the heating rate was 5 °C / min.

[0024] (2) Mix the pretreated aluminum plant sludge, silicon micropowder, and oyster shell powder in a certain proportion according to the formula and put them into the ball mill, add the corresponding amount of graphite pore-forming agent, dry ball mill and mix, and pass through 50 Mesh sieve. Add an appropriate amount of deionized water to the uniformly mixed powder for granulation, and carry out 24h aging treatment on the powder.

[0025] (3) Weigh 2 g of the powder that has be...

Embodiment 1

[0028] The weight ratio of the raw material formula: aluminum plant sludge 30wt%, silicon micropowder 23wt%, oyster shell 45 wt% and graphite powder 2 wt%, respectively put the aluminum plant sludge and oyster shell into a high-temperature box furnace at 900 ° C Pre-burn for 1 hour, then weigh the pretreated aluminum plant sludge, silicon micropowder, oyster shell powder and graphite powder in a certain proportion according to the formula and carry out ball milling and mixing. Take 2 g of powder that has been stale for 1 day, and mold it under the condition of a pressure of 2 MPa. The sample is placed in a high-temperature box furnace at 1000 °C for 2 h, and then cooled with the furnace to obtain a porous hollow columnar sample. Put the sintered sample in a hydrothermal kettle, add phosphoric acid solution, and carry out hydrothermal treatment at 5 MPa pressure and 300 °C for 8 h. After the hydrothermal treatment is completed, the sample is dried and the adsorption-growth aqueo...

Embodiment 2

[0033] The weight ratio of the raw material formula: aluminum plant sludge 35wt%, silica powder 28wt%, oyster shell 35 wt% and graphite powder 2 wt%, respectively put the aluminum plant sludge and oyster shell into a high-temperature box furnace at 900 ° C Pre-burn for 1 hour, then weigh the pretreated aluminum plant sludge, silicon micropowder, oyster shell powder and graphite powder in a certain proportion according to the formula and carry out ball milling and mixing. Take 2 g of powder that has been stale for 1 day, and mold it under the condition of a pressure of 2 MPa. The sample is placed in a high-temperature box furnace at 1000 °C for 2 h, and then cooled with the furnace to obtain a porous hollow columnar sample. Put the sintered sample in a hydrothermal kettle, add phosphoric acid solution, and carry out hydrothermal treatment at 5 MPa pressure and 300 °C for 8 h. After the hydrothermal treatment is completed, the sample is dried and the adsorption-growth aqueous pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com