Method for treating solid wastes by culturing biological leachate by use of membrane bioreactor

A membrane bioreactor and solid waste technology, which is applied in the direction of solid waste removal and process efficiency improvement, can solve the problems of rapid leaching of hazardous solid waste, slow growth, and anti-deficit, etc., and achieves a solution to biological oxidation. Inefficiency, increased microbial concentration, and shortened leaching cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

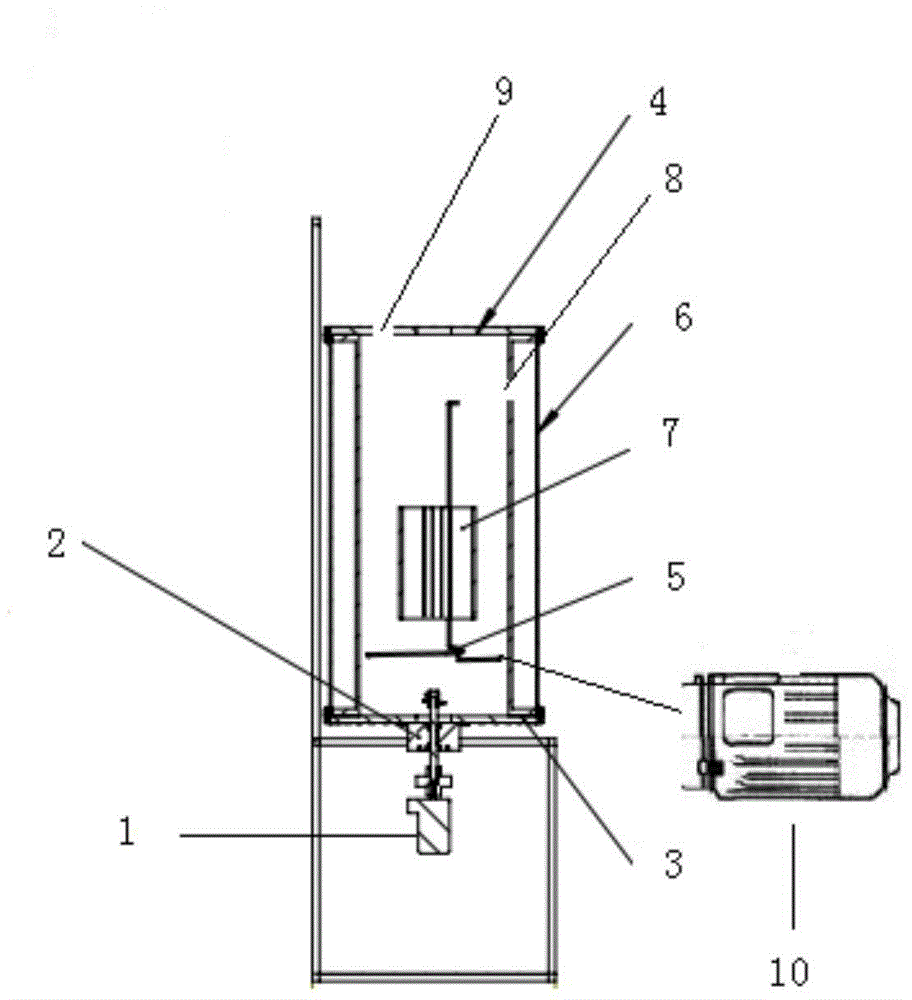

Image

Examples

Embodiment 1

[0027] Put Thiobacillus thiooxidans and Thiobacillus ferrooxidans into a 100L membrane bioreactor at a ratio of 1:1, and the membrane module is a polytetrafluoroethylene flat microfiltration membrane. Inorganic salt culture solution includes: (NH 4 ) 2 SO 4 ,1.0g / L; MgSO 4 ,0.5g / L; CaCl 2 ,0.1g / L; KH 2 PO 4 , 1.0g / L; sulfur, 16g / L. Tap water configuration, natural pH.

[0028]The external circulating water controls the temperature inside the reactor to be 30°C, the aeration rate is 20L / min, and the stirring speed is 100r / min. After running for 5 days, the pH of the culture solution dropped from 7.0 to 1.0, and the bacterial concentration was 1.2×10 9 pieces / ml. The inflow and outflow of the membrane bioreactor was started to maintain balance, and the flux was 2L / h. As the concentration of microorganisms in the reactor increased, the pH of the effluent gradually decreased and stabilized at 0.90. The membrane bioreactor produces approximately 50 liters of bioleachate ...

Embodiment 2

[0030] Thiobacillus thiooxidans, Thiobacillus ferrooxidans and Leptospira ferrooxidans were introduced into a 200L membrane bioreactor at a ratio of 1:1:1, and the membrane module was a polytetrafluoroethylene flat microfiltration membrane. Inorganic salt culture medium includes: KNO 3 ,1.0g / L; MgCl 2 ,0.5g / L; CaCl 2 ,0.1g / L; KH 2 PO 4 , 1.0g / L; Sulfur, 24g / L. Tap water configuration, natural pH.

[0031] The temperature inside the reactor is controlled by external circulating water to be 30°C, the aeration rate is 50L / min, and the stirring speed is 80r / min. After running for 5 days, the pH of the culture solution dropped from 7.0 to 1.0, and the bacterial concentration was 1.0×10 9 pieces / ml. The inflow and outflow of the membrane bioreactor was started to maintain balance, and the flux was 6L / h. As the concentration of microorganisms in the reactor increased, the pH of the effluent gradually decreased and stabilized at 1.0. The membrane bioreactor produces approxima...

Embodiment 3

[0033] Put Thiobacillus thiooxidans and Leptospira ferrophilum at a ratio of 1:1 into a 100L membrane bioreactor, and the membrane module is a hollow fiber membrane. Inorganic salt culture medium includes: KNO 3 ,1.0g / L; MgSO 4 ,0.5g / L; CaCl 2 ,0.1g / L; K 2 HPO 4 , 1.0g / L; sulfur, 12g / L; pyrite, 12g / L. Tap water configuration, natural pH.

[0034] The temperature inside the reactor is controlled by external circulating water to be 35°C, the aeration rate is 40L / min, and the stirring speed is 120r / min. After running for 5 days, the pH of the culture solution dropped from 7.0 to 1.0, and the bacterial concentration was 1.2×10 9 pieces / ml. The inflow and outflow of the membrane bioreactor was started to maintain balance, and the flux was 3L / h. As the concentration of microorganisms in the reactor increased, the pH of the effluent gradually decreased and stabilized at 0.90. The membrane bioreactor produces approximately 75 liters of bioleachate at a pH of 0.9 per day. Zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com