Rubber roller grinding wheel and manufacturing method thereof

A grinding wheel and rubber grinding technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of reducing the quality and service life of grinding wheels, increasing the manufacturing cost of large-pore grinding wheels, weakening the holding force of bonding agents and abrasives, etc. , to achieve the effects of improving processing quality and labor efficiency, realizing material saving, energy saving and emission reduction, and stable and reliable process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

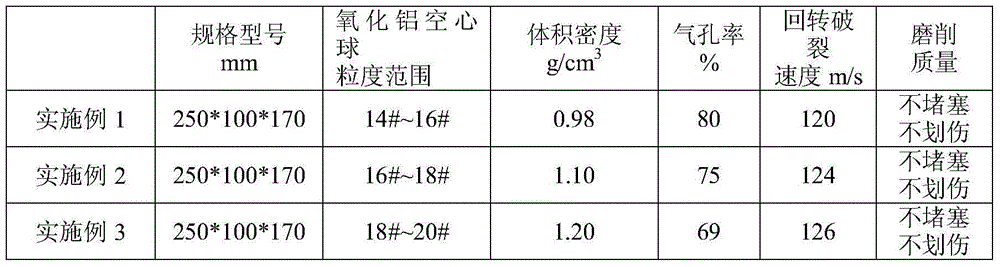

Embodiment 1

[0015] Mix aluminum oxide hollow balls 14#-16# and low-temperature high-strength vitrified bond according to the mass ratio of 85:15, and add 3% dextrin powder and 4% dextrin liquid based on the total weight of the binary formula and mix evenly , Feed into a mold of a certain specification, combed and scraped, pressed into shape with a press, demolded, dried, kiln sintered and processed to meet the requirements. The low-temperature high-strength vitrified bonding agent is composed of the following components, each component is calculated by weight percentage: 20% of clay, 30% of feldspar, and 50% of boron glass.

Embodiment 2

[0017] Mix aluminum oxide hollow spheres 16#-18# and low-temperature high-strength vitrified bond at a mass ratio of 82:18, and add 3% dextrin powder and 5% dextrin solution based on the total weight of the binary formula to mix, Feeding in a mold of a certain specification, combing and scraping, pressing to shape with a press, demoulding, drying, kiln sintering and processing to meet the requirements. The low-temperature high-strength vitrified bond is composed of the following components, each component is calculated by weight percentage: 22% of clay, 34% of feldspar, and 44% of boron glass.

Embodiment 3

[0019] Mix aluminum oxide hollow balls 18#-20# and low-temperature high-strength vitrified bond according to the mass ratio of 80:20, and take the total weight of the binary formula as the measurement basis, and add 3% dextrin powder and 6% dextrin liquid Mixing, feeding in a mold of a certain specification, combing and scraping, pressing and forming with a press, demoulding, drying, kiln sintering and processing to meet the requirements. The low-temperature high-strength vitrified bond is composed of the following components, each component is calculated by weight percentage: 15% of clay, 25% of feldspar, and 60% of boron glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com