A kind of preparation method of multifunctional textile

A multi-functional, textile technology, applied in the direction of textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of the decline of the breathable and moisture-permeable function of textiles, the decrease of the added value of textiles, etc., to achieve increased bonding fastness, good synergy, The effect of good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

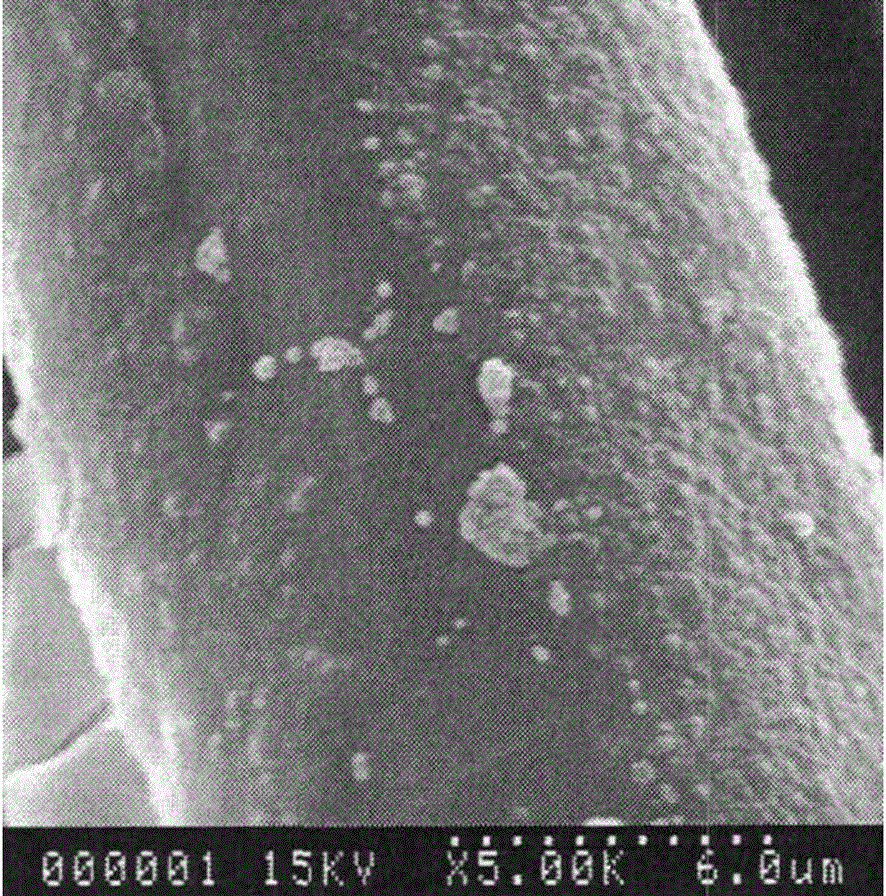

[0041] Embodiment 1: the preparation of multifunctional cotton fabric, concrete method is:

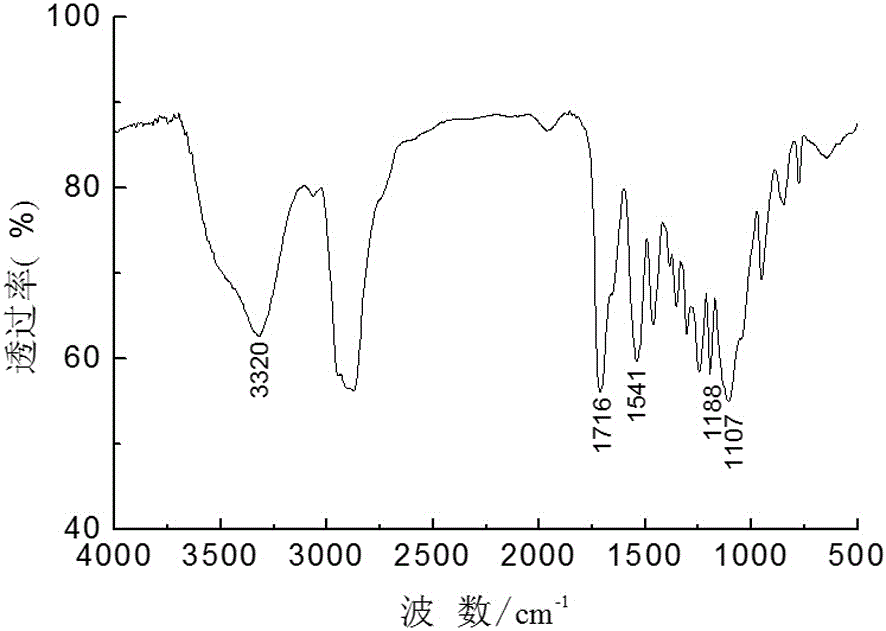

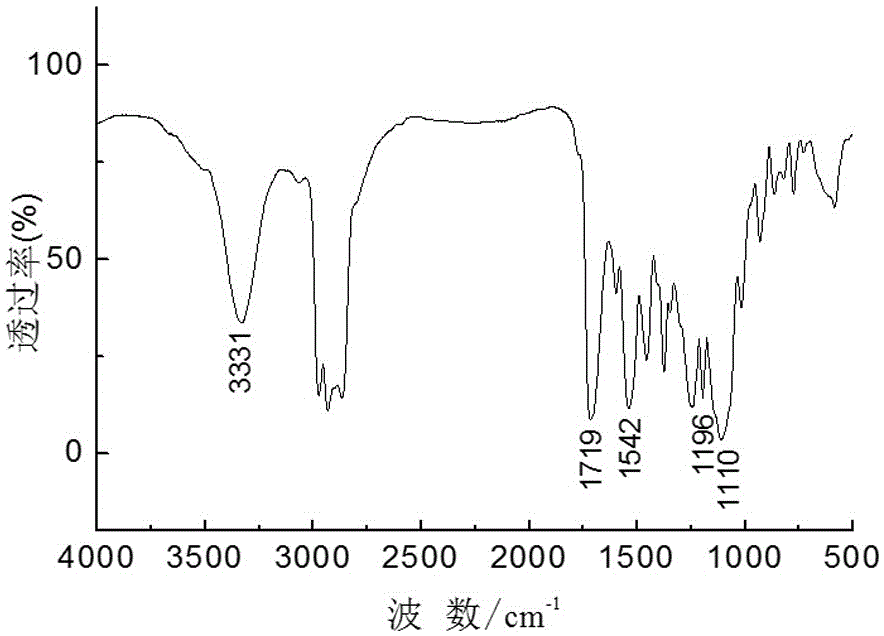

[0042] (1) Synthesis of low temperature crosslinking agent

[0043] Add 200g of polyethylene glycol and 0.05g of initiator dibutyltin dilaurate after vacuum dehydration and drying into a reaction vessel equipped with a stirrer, a thermometer, and a condensation reflux device, start stirring, raise the temperature to 40°C, and dissolve 21.5g Add terexylylene diisocyanate (XDI) into the reaction vessel. After the addition is complete, raise the temperature to 70°C for 3 hours under the protection of nitrogen, and then cool down to room temperature to obtain the polyurethane intermediate; then cool it in an ice-water bath, and add 12g in batches Sodium bisulfite was reacted at 5°C for 2.5 hours, and 545g of deionized water was added to control the solid content of the target product to about 30%. After high-speed stirring and emulsification, a milky white low-temperature crosslinking agen...

Embodiment 2

[0054] Embodiment 2: the preparation of multifunctional polyester fabric, concrete method is:

[0055] (1) Synthesis of low temperature crosslinking agent

[0056] Add 200g of polyethylene glycol and 0.09g of initiator dibutyltin dilaurate after vacuum dehydration and drying into a reaction vessel equipped with a stirrer, a thermometer, and a condensation reflux device, start stirring, raise the temperature to 45°C, and dissolve 24.5g Add terexylylene diisocyanate (XDI) into the reaction vessel. After the addition is complete, raise the temperature to 75°C for 2.5 hours under the protection of nitrogen, and then cool it down to room temperature to obtain the polyurethane intermediate; then cool it in an ice-water bath and put it in batches 13.5g of sodium bisulfite was reacted at 3°C for 2.5h, and 555g of deionized water was added to control the solid content of the target product to about 30%. After high-speed stirring and emulsification, a milky white low-temperature cross...

Embodiment 3

[0067] Embodiment 3: the preparation of multifunctional nylon fabric, concrete method is:

[0068] (1) Synthesis of low temperature crosslinking agent

[0069] Add 200g of polyethylene glycol and 0.12g of initiator dibutyltin dilaurate after vacuum dehydration and drying into a reaction vessel equipped with a stirrer, a thermometer, and a condensation reflux device, start stirring, and heat up to 50°C. Add xylylene diisocyanate (XDI) into the reaction vessel, after the addition, raise the temperature to 80°C for 2 hours under the protection of nitrogen, and cool down to room temperature to obtain the polyurethane intermediate; then cool it in an ice-water bath, and put 15g of Sodium bisulfate was reacted at 5°C for 2 hours, and 565g of deionized water was added to control the solid content of the target product to about 30%. After emulsification with high-speed stirring, a milky white low-temperature crosslinking agent was obtained.

[0070] (2) Preparation of nano-silica sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com