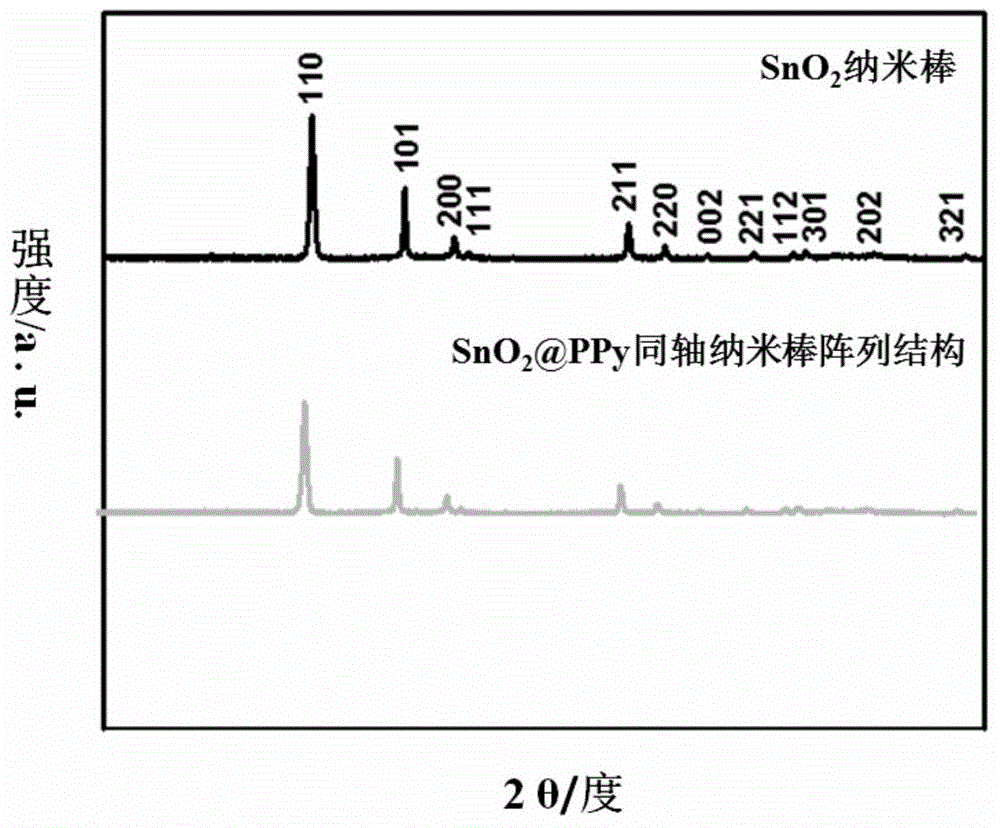

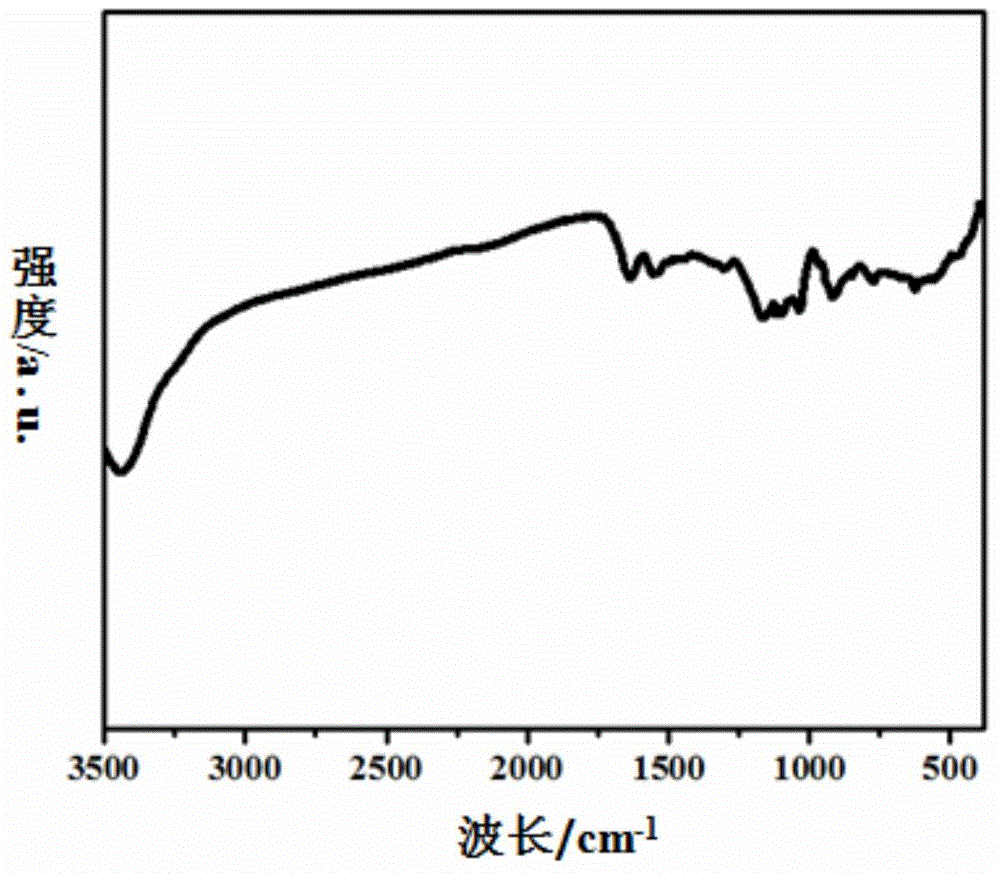

SnO2@PPy coaxial nanorod array structure material, preparation method and application of material

A technology of nanorod arrays and structural materials, which is applied in the fields of nanomaterials and electrochemistry, can solve the problems of destroying cycle performance and low lithium ion conductivity, and achieves the effects of inhibiting cracking, inhibiting capacity decay, and facilitating market promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

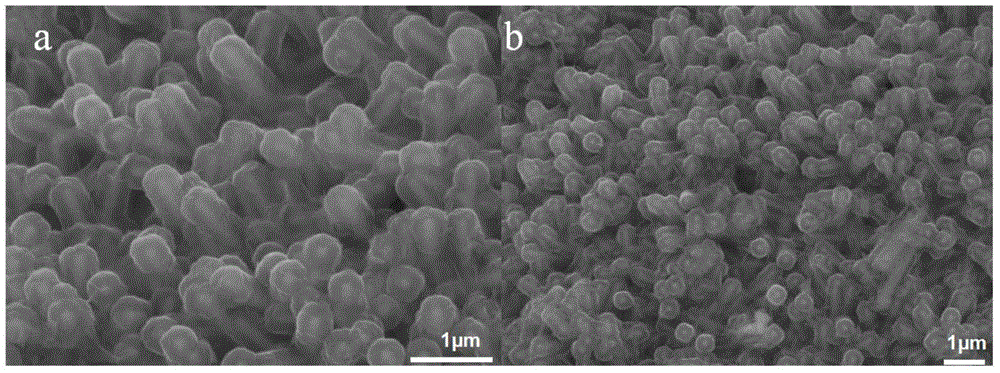

Embodiment 1

[0023] 1) Add 0.0038mol of SnCl to the container 4 .5H 2 O and 0.031mol of NaOH, then add 30ml of deionized water, stir in air for 30min;

[0024] 2) Add 0.0013mol of NH to the solution 4 F, continue stirring for 30min;

[0025] 3) Put the foamed nickel (a square with a diameter of 2.5cm) that has been cleaned and acidified into the reactor and pour the solution obtained in step 2), put the reactor into a 200°C oven for hydrothermal reaction for 24h, and obtain Grown SnO 2 Nickel foam with nanorod arrays;

[0026] 4) Disperse pyrrole monomer in 50ml lithium perchlorate acetonitrile solution, wherein the concentration of pyrrole monomer is 10mmol L -1 , the lithium perchlorate concentration is 100mmol L -1 , mixed and stirred for 30min;

[0027] 5) With already grown SnO 2 The nickel foam of the nanorod array was used as the working electrode, the Ag / AgCl was used as the reference electrode, and the platinum electrode was used as the counter electrode to perform electro...

Embodiment 2

[0033] 1) Add 0.0038mol of SnCl to the container 4 .5H 2 O and 0.031mol of NaOH, then add 30ml of deionized water, stir in air for 30min;

[0034] 2) Add 0.0013mol of NH to the solution 4 F, continue stirring for 30min;

[0035] 3) Put the foamed nickel (a square with a diameter of 2.5 cm) that has been cleaned and acidified into the reactor and pour the solution obtained in step 2), and put the reactor into a 200 ° C oven for hydrothermal reaction for 24 hours to obtain Grown SnO 2 Nickel foam with nanorod arrays;

[0036] 4) Disperse pyrrole monomer in 50ml lithium perchlorate acetonitrile solution, wherein the concentration of pyrrole monomer is 50mmol L -1 , the lithium perchlorate concentration is 50mmol L -1 , mixed and stirred for 30min;

[0037] 5) With already grown SnO 2 The nickel foam of the nanorod array was used as the working electrode, the Ag / AgCl was used as the reference electrode, and the platinum electrode was used as the counter electrode for elect...

Embodiment 3

[0040] 1) Add 0.0038mol of SnCl to the container 4 .5H 2 O and 0.031mol of NaOH, then add 30ml of deionized water, stir in air for 30min;

[0041] 2) Add 0.0013mol of NH to the solution 4 F, continue stirring for 30min;

[0042] 3) Put the cleaned and acidified nickel foam (a square with a diameter of 2.5 cm) into the reactor and pour the solution obtained in step 2), and put the reactor into a 200°C oven for hydrothermal reaction for 24 hours.

[0043] 4) Disperse pyrrole monomer in 50ml lithium perchlorate acetonitrile solution, wherein the concentration of pyrrole monomer is 100mmol L -1 , the lithium perchlorate concentration is 10mmol L -1 , mixed and stirred for 30min;

[0044] 5) With already grown SnO 2 The nickel foam of the nanorod array was used as the working electrode, the Ag / AgCl was used as the reference electrode, and the platinum electrode was used as the counter electrode for electrodeposition on a CHI760D electrochemical workstation for 700s, with a cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com