Platinum-based catalyst carrier of proton exchange membrane fuel cell (PEMFC) and preparation method of platinum-based catalyst carrier

A catalyst carrier and proton exchange membrane technology, applied in the field of materials, can solve problems such as poor electrical conductivity, achieve the effects of enhancing stability, reducing precious metal loading, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

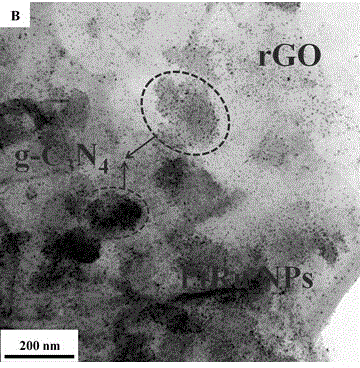

[0031] Specific implementation mode 1: This implementation mode prepares g-C according to the following steps 3 N 4 / Graphene-like carbon composite carrier material:

[0032] Weigh 5g of melamine and 10g of sodium chloride, add 20mL of ultrapure water to it, and ultrasonically disperse for 1 hour to obtain a milky white slurry, then freeze-dry it, put it in a porcelain boat after grinding, wrap it with copper foil, and put the porcelain boat into the tube In a nitrogen atmosphere of a type furnace, at 10°C min -1 Raise the temperature to 550°C at the heating rate and keep it for 2 hours, wash it with ultrapure water after cooling to room temperature, and dry it in vacuum at 70°C to obtain block g-C 3 N 4 Material. Weigh 1g of the above block g-C 3 N 4 And add 20ml of concentrated sulfuric acid and 20ml of concentrated nitric acid mixed solution, ultrasonic 6h, after stirring overnight, use ultrapure water to filter and wash to neutral, freeze-dry to obtain g-C 3 N 4Na...

specific Embodiment approach 2

[0033] Specific embodiment two: this embodiment prepares g-C according to the following steps 3 N 4 Nanosheet / graphene-like carbon composite support material:

[0034] Weigh 5g of urea and 10g of sodium chloride, add 20mL of ultrapure water to it, ultrasonically disperse for 1 hour to obtain a milky white slurry, then freeze-dry it, put it in a porcelain boat after grinding, wrap it with copper foil, and put the porcelain boat into the tube In a nitrogen atmosphere of a type furnace, at 10°C min -1 Raise the temperature to 550°C at the heating rate and keep it for 2 hours, wash it with ultrapure water after cooling to room temperature, and dry it in vacuum at 70°C to obtain block g-C 3 N 4 Material. Weigh 1g of the above block g-C 3 N 4 And add 20ml of concentrated sulfuric acid and 20ml of concentrated nitric acid mixed solution, ultrasonic 6h, after stirring overnight, use ultrapure water to filter and wash to neutral, freeze-dry to obtain g-C 3 N 4 Nanosheets. Weig...

specific Embodiment approach 3

[0035] Specific embodiment three: this embodiment prepares g-C according to the following steps 3 N 4 Nanosheet / graphene-like carbon composite support material:

[0036] Weigh 5g of melamine and 10g of sodium chloride, add 20mL of ultrapure water to it, and ultrasonically disperse for 1 hour to obtain a milky white slurry, then freeze-dry it, put it in a porcelain boat after grinding, wrap it with copper foil, and put the porcelain boat into the tube In a nitrogen atmosphere of a type furnace, at 10°C min -1 Raise the temperature to 550°C at the heating rate and keep it for 2 hours, wash it with ultrapure water after cooling to room temperature, and dry it in vacuum at 70°C to obtain block g-C 3 N 4 Material. Weigh 1g of the above block g-C 3 N 4 And add 20ml of concentrated sulfuric acid and 20ml of concentrated nitric acid mixed solution, ultrasonic 6h, after stirring overnight, use ultrapure water to filter and wash to neutral, freeze-dry to obtain g-C 3 N 4 Nanoshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com