High silica fiber woven film-coated filter material for coal-fired boiler and preparation method

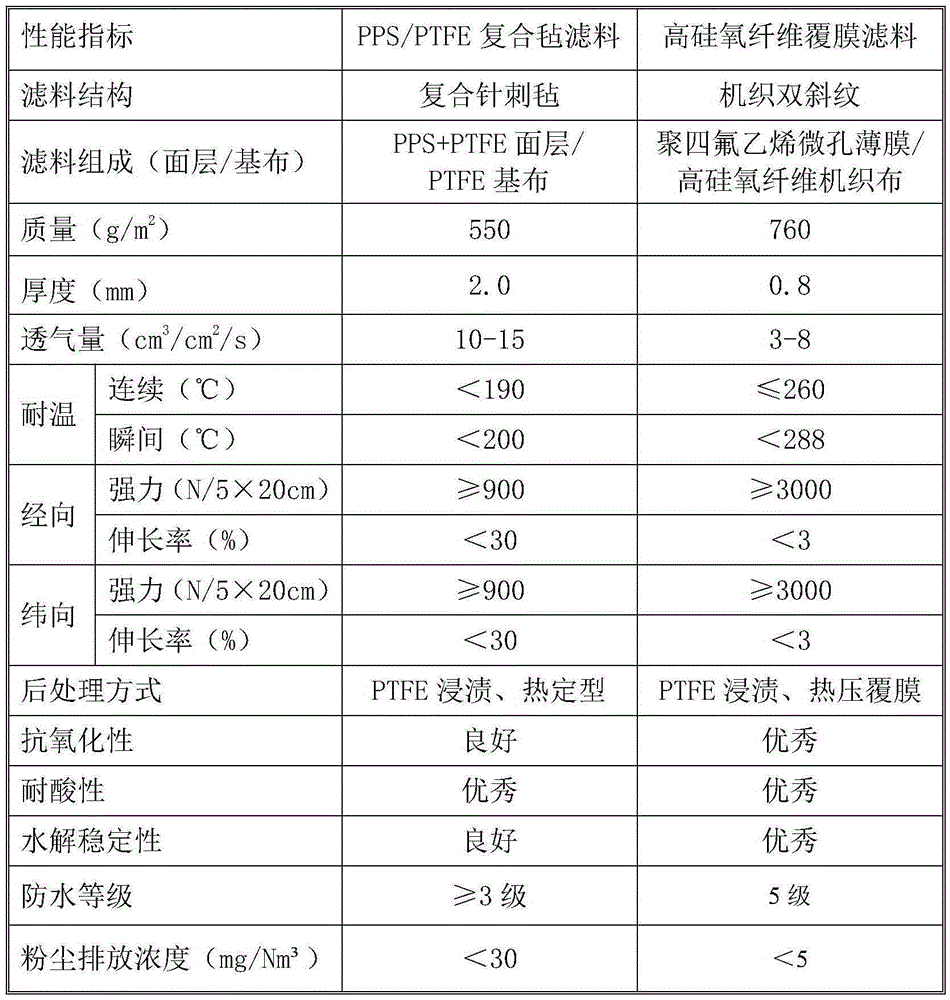

A high-silica fiber, membrane-coated filter material technology, applied in separation methods, chemical instruments and methods, and textile material processing, etc., can solve problems such as high energy consumption and short service life, and achieve high filtration accuracy and corrosion resistance. The effect of improved performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select high-quality high-silica fibers with a silica content greater than 96% and twist them into yarns to make 156tex and 204tex yarns respectively. 204tex yarn high-silica fiber yarn is bulked, and the blowing pressure is 0.6bar high-pressure airflow, so that the yarn is fluffy, the surface is more hairy, the specific surface area is increased, the dust collection efficiency is improved, and the bulking speed of the bulked yarn machine is improved. 280m / min.

[0035] The 156tex high-silica fiber yarn enters the sizing process, and the surface of the yarn is covered with a layer of size to improve the weaving performance of the product, reduce end breakage and fabric surface defects, and improve quality and production efficiency. The low-temperature sizing process is adopted, the slurry temperature is 80°C, and the sizing speed is 60m / min.

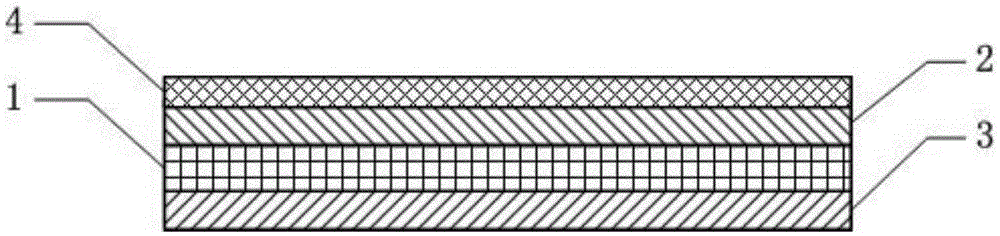

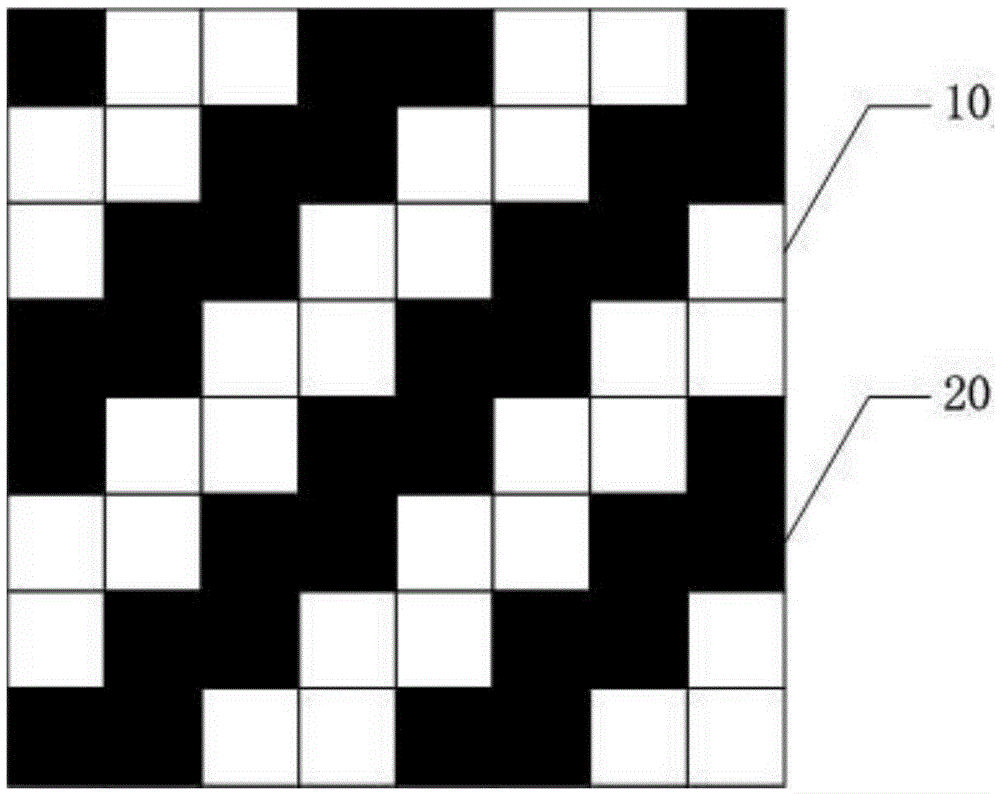

[0036] The weaving process adopts the double-layer variable twill weaving process, so that the product has a double-layer struct...

Embodiment 2

[0041] Select high-quality high-silica fibers with a silica content greater than 96% and twist them into yarns to make 136tex and 204tex yarns respectively. 204tex yarn high-silica fiber yarn is bulked, and the blowing pressure is 0.6bar high-pressure airflow, so that the yarn is fluffy, the surface is more hairy, the specific surface area is increased, the dust collection efficiency is improved, and the bulking speed of the bulked yarn machine is improved. 280m / min.

[0042] The 136tex high-silica fiber yarn enters the sizing process, and the surface of the yarn is covered with a layer of size to improve the weaving performance of the product, reduce end breakage and fabric surface defects, and improve quality and production efficiency. The low-temperature sizing process is adopted, the slurry temperature is 80°C, and the sizing speed is 60m / min.

[0043] The weaving process adopts the double-layer variable twill weaving process, so that the product has a double-layer struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com