Preparation method and application of carbon nanotube supported nano titanium dioxide adsorbent with multi-stage structure

A technology of nano-titanium dioxide and carbon nanotubes, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of affecting the water effluent effect, not easy to settle, and low bulk density, so as to achieve easy recycling and Effects of regeneration, ease of transportation, and increased bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

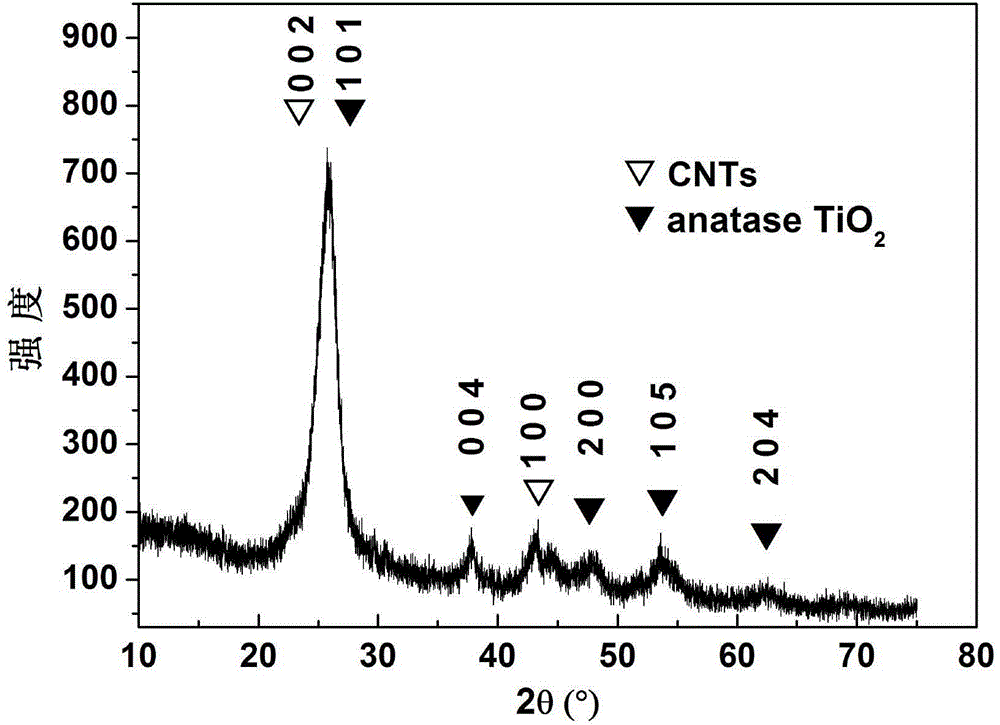

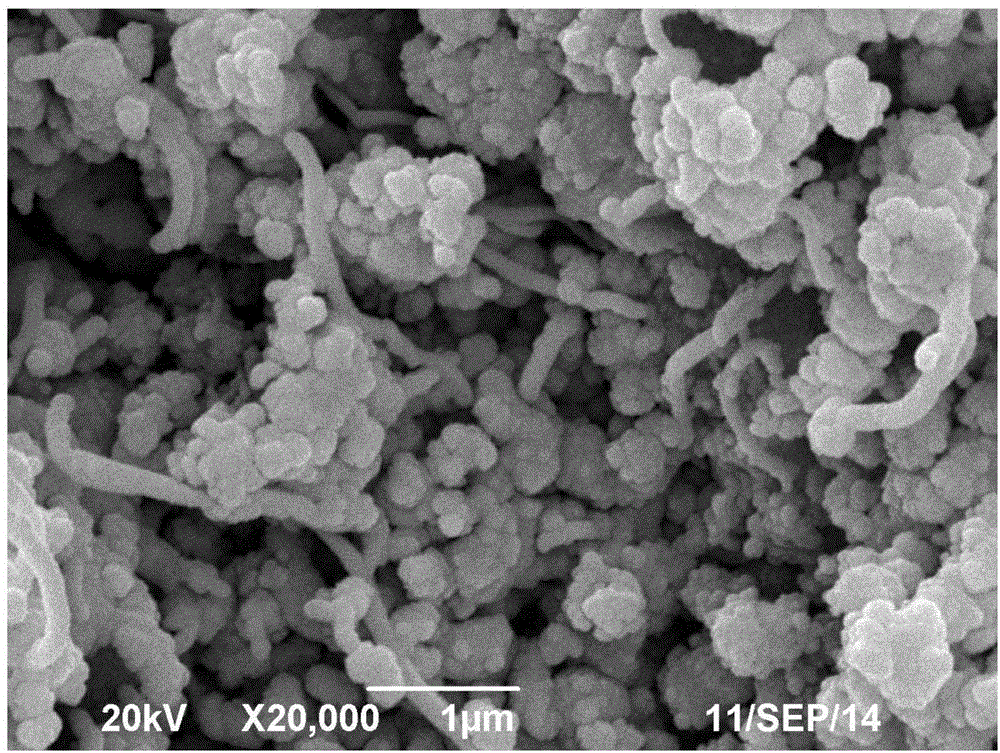

[0033] A preparation method of the carbon nanotube-supported multi-level structure nano titanium dioxide adsorbent of the present invention includes the following steps:

[0034] (1) Put 4g of carbon nanotubes with a diameter of 30-50nm into a 250mL three-necked flask, and then add 150mL with a concentration of 18.4mol·L -1 The concentration of concentrated sulfuric acid and 50mL is 14mol·L -1 Concentrated nitric acid, ultrasonically dispersed for 10 minutes, reflux oxidation treatment at a temperature of 60 ℃ for 4 hours, after reflux oxidation treatment is poured into water to stop the reaction, centrifuged, and then washed with ultrapure water until the pH of the filtrate is neutral; Scrape off the filter cake layer, then dry it at 80°C for 2 hours, and grind it into powder to obtain surface-treated carbon nanotubes;

[0035] (2) Take 0.3 g of the surface-treated carbon nanotubes prepared in the above step (1) and add them to 50 mL of ethanol for ultrasonic treatment for 10 minut...

Embodiment 2

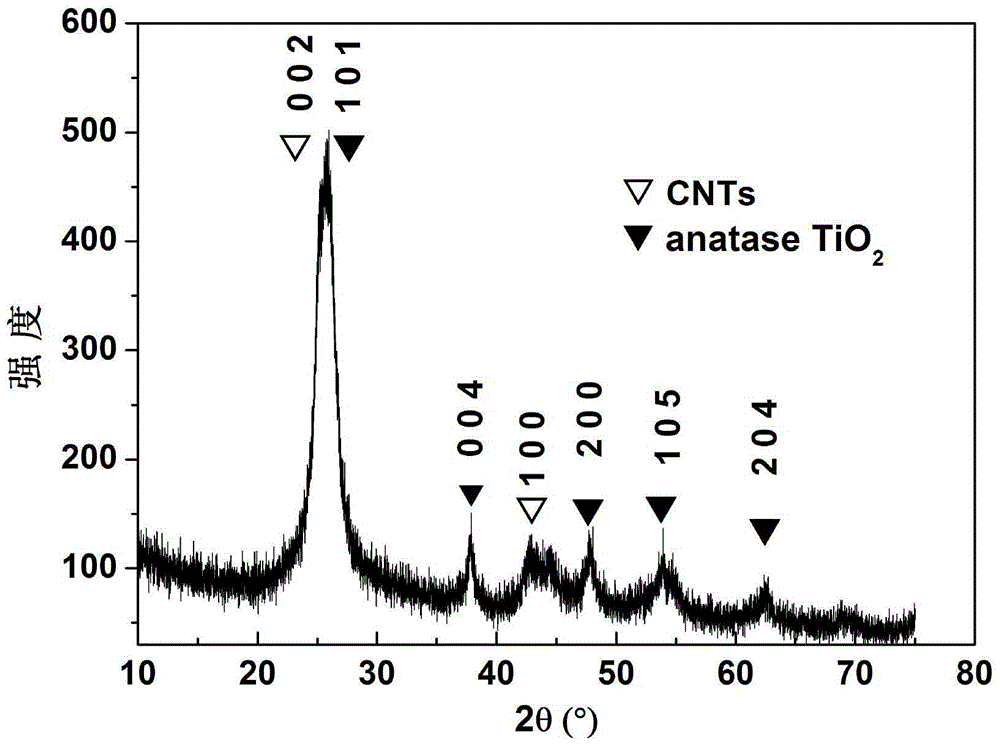

[0040] A method for preparing the carbon nanotube-loaded multi-level structure nano titanium dioxide adsorbent of the present invention includes the following steps:

[0041] (1) Put 2g of carbon nanotubes with a diameter of 30-50nm into a 250mL three-necked flask, and then add 100mL with a concentration of 18.4mol·L -1 The concentration of concentrated sulfuric acid and 50mL is 10mol·L -1 After the concentrated hydrochloric acid, ultrasonically dispersed for 10min, reflux oxidation treatment at 40℃ for 6h, after reflux oxidation treatment, pour into water to stop the reaction, centrifuge, and then wash with ultrapure water until the pH of the filtrate is neutral; Scrape the filter cake layer, then dry it at 80°C for 5 hours, grind it into powder, and obtain surface-treated carbon nanotubes;

[0042] (2) Take 0.5 g of the surface-treated carbon nanotubes prepared in the above step (1) and add them to 80 mL of ethanol for ultrasonic treatment for 10 minutes, add 5 mL of water, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com