CoO/C catalyst and preparation method thereof

A technology of catalyst and solvent, which is applied in the field of oxygen reduction catalyst, can solve the problems of difficult removal of protective agent and high price of organic cobalt salt, and achieve the effects of low cost, good stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

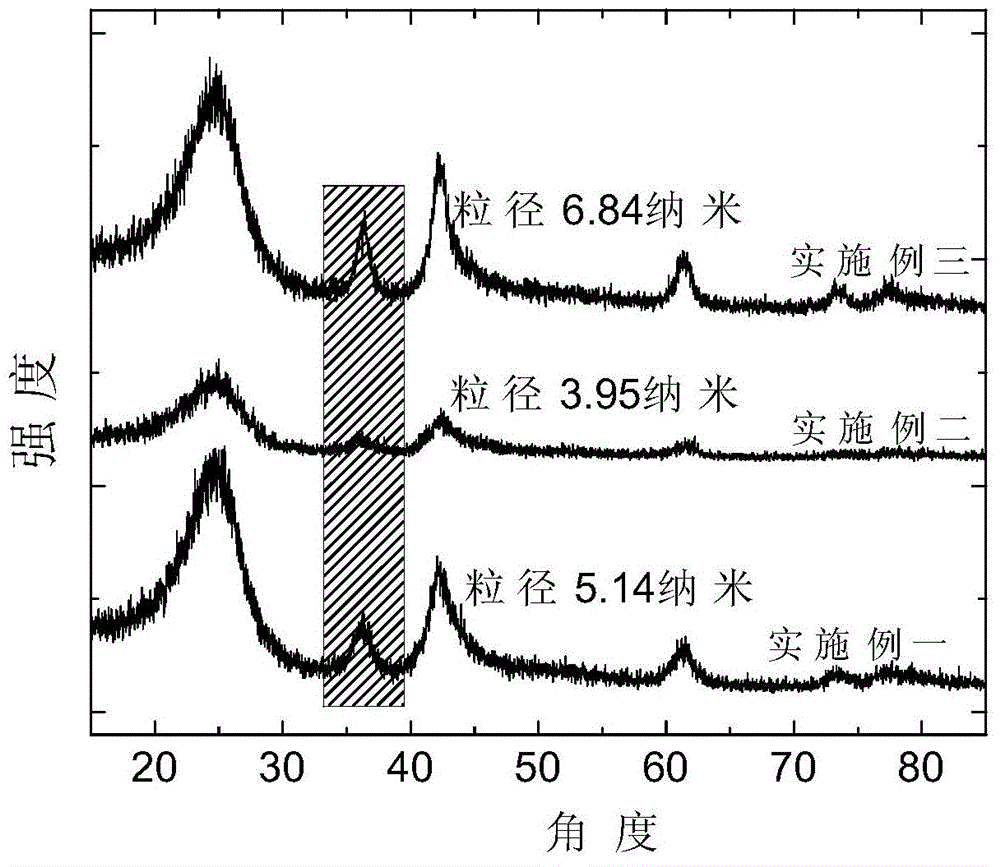

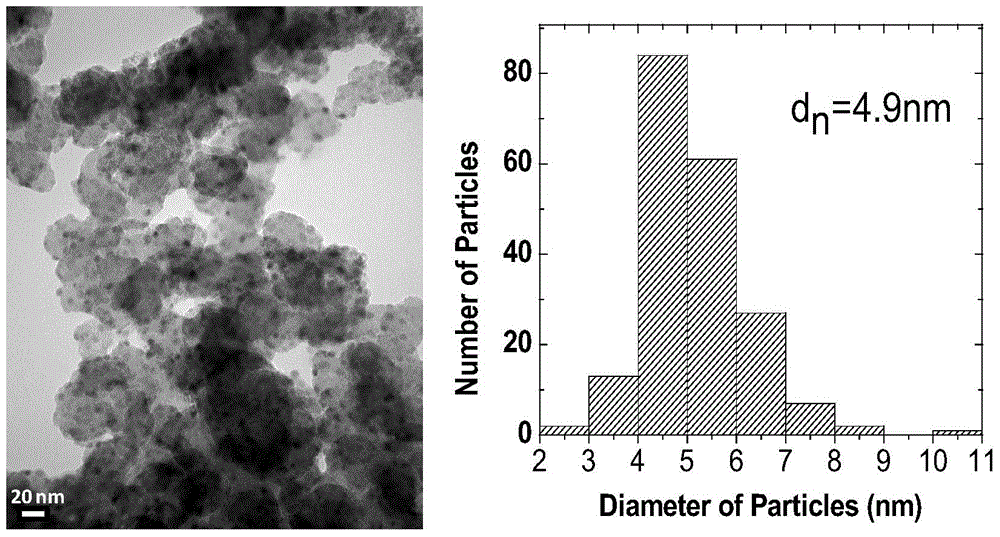

Embodiment 1

[0035] First, add 0.25g Co(OAc) 2 ·4H 2 Dissolve O in 25mL of absolute ethanol, add 1.25mL of 25w.t.% ammonia, place the mixture in the air and stir for 15min; then transfer it to an oil bath at 100℃ for heating to reflux, cooling down after 3.5h, and cooling naturally To room temperature to get CoO x colloid.

[0036] Weigh 80 mg of Vulcan XC-72 carbon black, add 25 mL of absolute ethanol, and ultrasonically disperse uniformly; add 1 mL of the obtained CoO to this slurry x The colloidal solution (metal Co mass is 5mg), magnetically stirred at room temperature for 6h. Then the mixture was passed through a rotary evaporator to remove the solvent and placed in an air oven at 80°C for 8 hours to obtain CoO x / C. The obtained black powder CoO x / C is ground, weighed and placed in a quartz boat, then transferred to a tube furnace, and placed in N 2 5℃min under the atmosphere -1 The rate of heating is programmed to 500℃, and the target product 5.88%CoO / C catalyst is obtained by treatin...

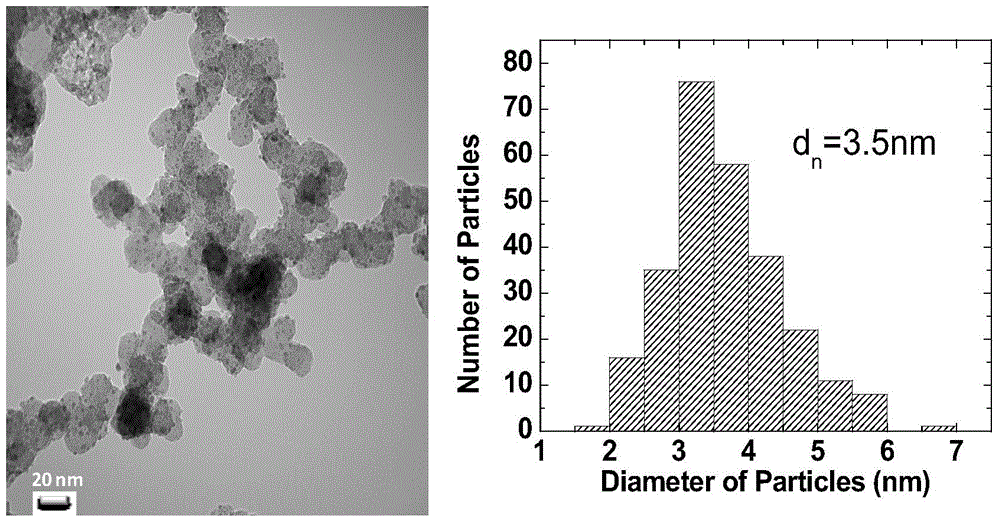

Embodiment 2

[0038] First, add 0.5g Co(OAc) 2 ·4H 2 O was dissolved in 25mL of absolute ethanol, 2.5mL of 25w.t.% ammonia was added, and the mixture was placed in the air and stirred for 15min; then it was transferred to an oil bath at 100℃ for heating and refluxing. After 3.5h, the temperature was cooled down naturally. To room temperature to get CoO x colloid.

[0039] Weigh 80 mg of Vulcan XC-72 carbon black, add 25 mL of absolute ethanol, and ultrasonically disperse uniformly; add 1 mL of the obtained CoO to this slurry x The colloidal solution (metal Co mass is 5mg), magnetically stirred at room temperature for 6h. Then the mixture was passed through a rotary evaporator to remove the solvent and placed in an air oven at 80°C for 8 hours to obtain CoO x / C. The obtained black powder CoO x / C is ground, weighed and placed in a quartz boat, then transferred to a tube furnace, and placed in N 2 5℃min under the atmosphere -1 The rate of heating is programmed to 500℃, and the target product 5....

Embodiment 3

[0041] First, add 1.25g Co(OAc) 2 ·4H 2 Dissolve O in 25mL of absolute ethanol, add 6.25mL of 25w.t.% ammonia, place the mixture in the air and stir for 15min; then transfer it to an oil bath at 100℃ for heating to reflux, cooling down after 3.5h, and cooling naturally To room temperature to get CoO x colloid.

[0042] Weigh 80 mg of Vulcan XC-72 carbon black, add 25 mL of absolute ethanol, and ultrasonically disperse uniformly; add 1 mL of the obtained CoO to this slurry x The colloidal solution (metal Co mass is 5mg), magnetically stirred at room temperature for 6h. Then the mixture was passed through a rotary evaporator to remove the solvent and placed in an air oven at 80°C for 8 hours to obtain CoO x / C. The obtained black powder CoO x / C is ground, weighed and placed in a quartz boat, then transferred to a tube furnace, and placed in N 2 5℃min under the atmosphere -1 The rate of heating is programmed to 500℃, and the target product 5.88%CoO / C catalyst is obtained by treatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com