Steam ejecting type organic garbage disposer with limiting inclined edge

A technology for waste treatment and organic matter, which is applied in the field of steam ejection organic matter waste treatment machines, can solve problems such as the inability of equipment to meet the requirements, and achieve the effect of convenient feeding and fast feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

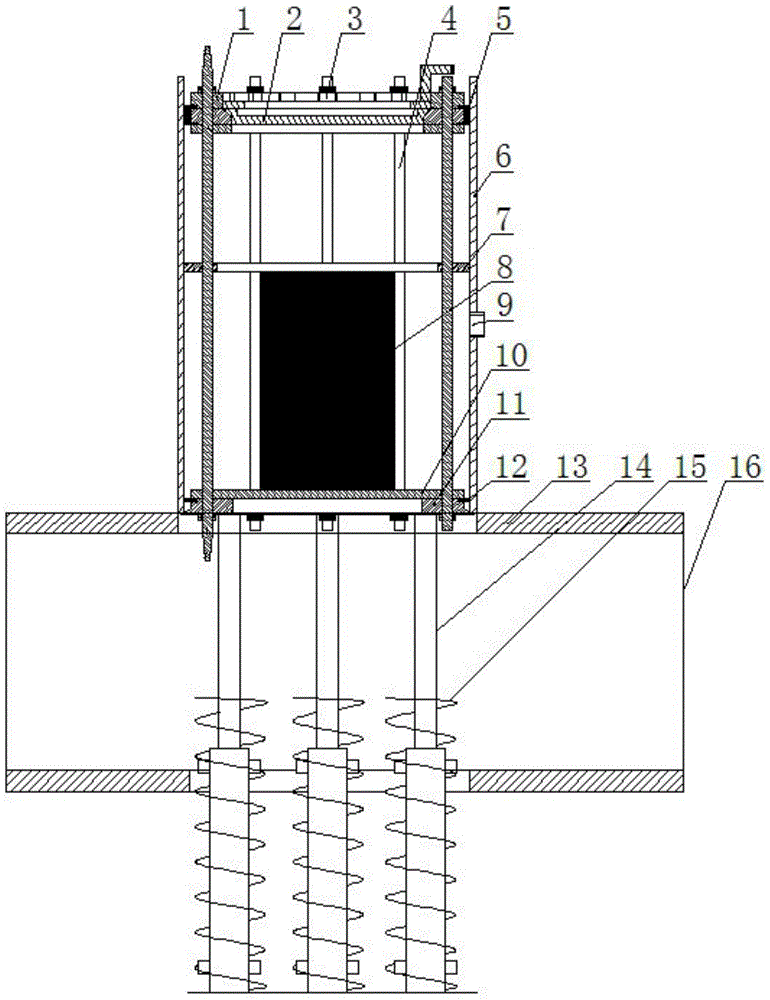

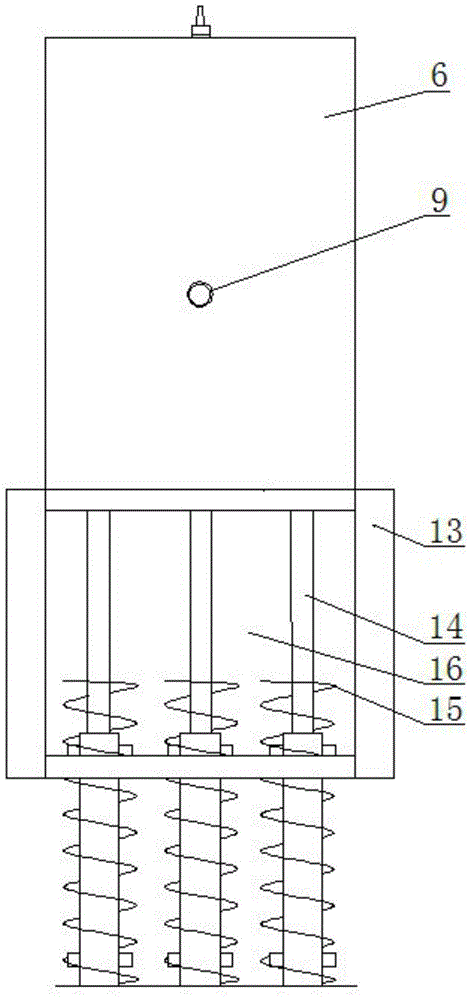

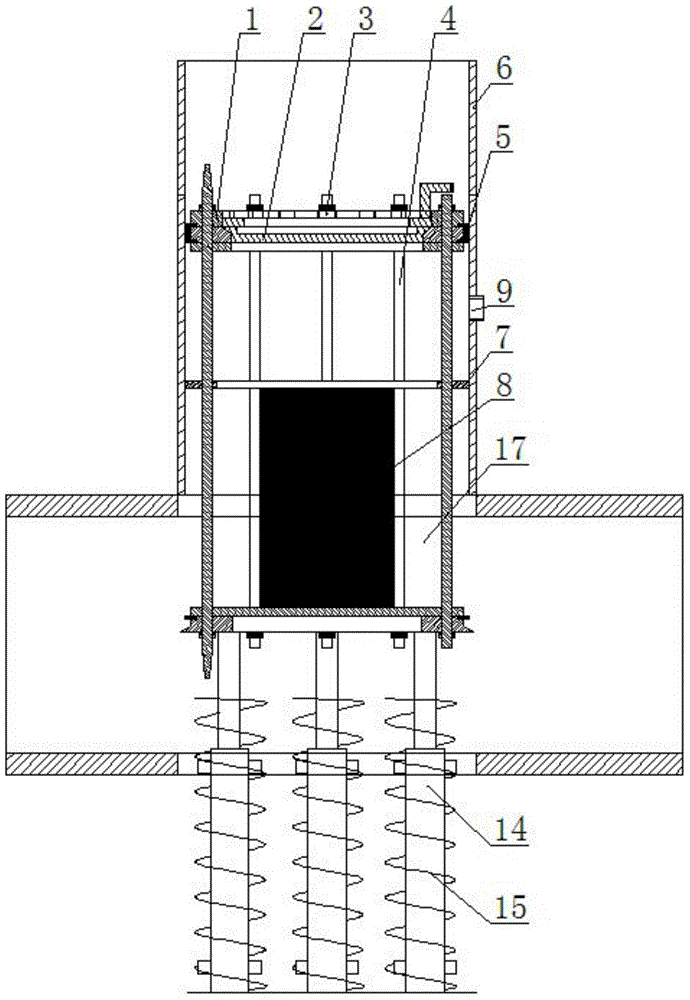

[0034] A steam catapult type organic waste disposal machine with a limiting hypotenuse, comprising a steam pressure-holding steel cylinder 6, an catapult steel cage, a feed screw cap 2 and a catapult triggering cylinder 14, the catapult steel cage is slidably installed on the steam pressure-holding steel cylinder Inside, a steam inlet 9 is formed on the steam pressure-holding steel cylinder, a feed inlet 19 is formed on the upper end of the ejection steel cage, and the lower end of the ejection steel cage is fixed with the piston rod of the ejection trigger cylinder. The number of the ejection trigger cylinders can be determined according to the actual situation. It needs to be arranged. The present invention adopts 4 ejection triggering cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com