Patents

Literature

31results about How to "Eject evenly and orderly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

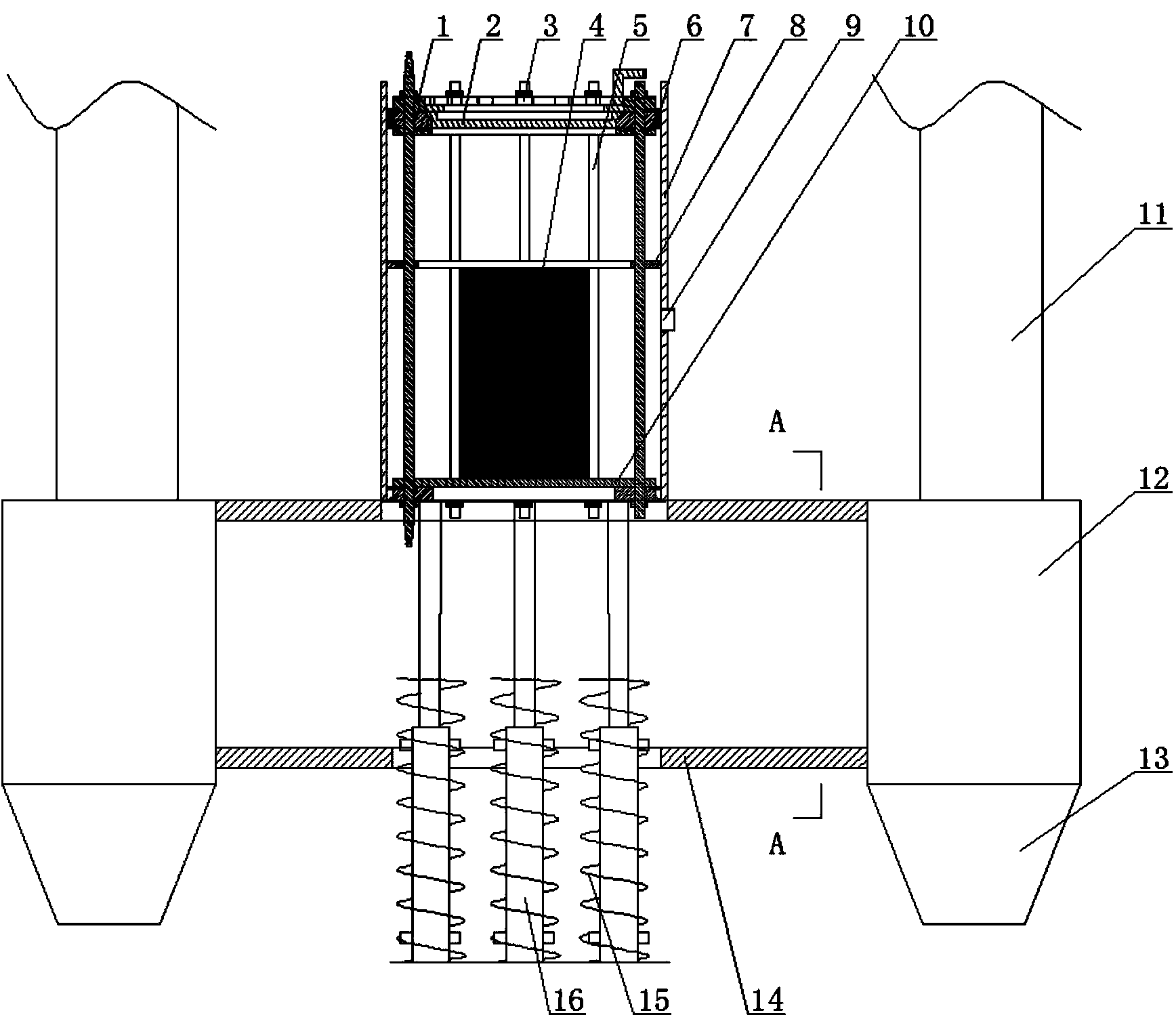

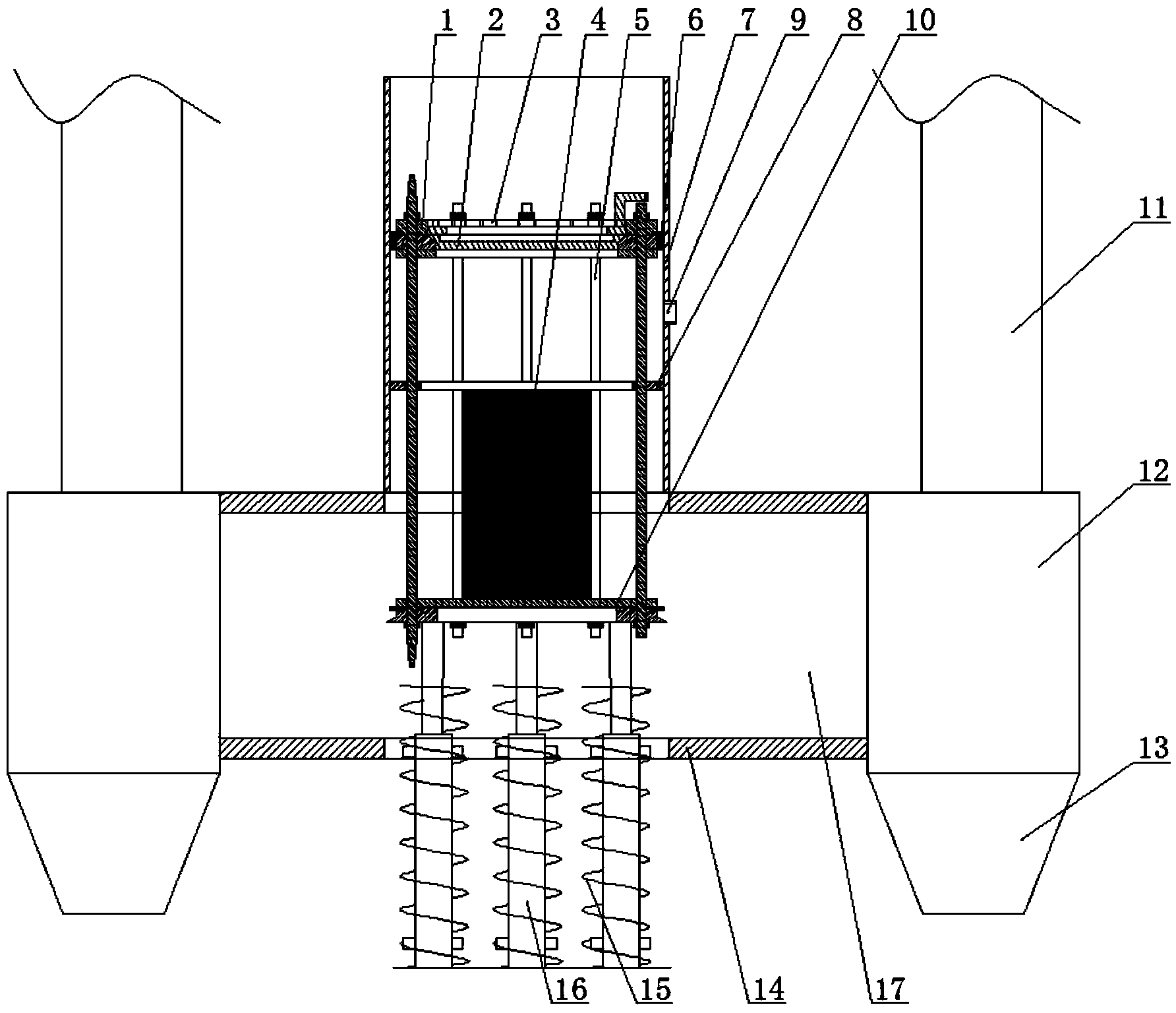

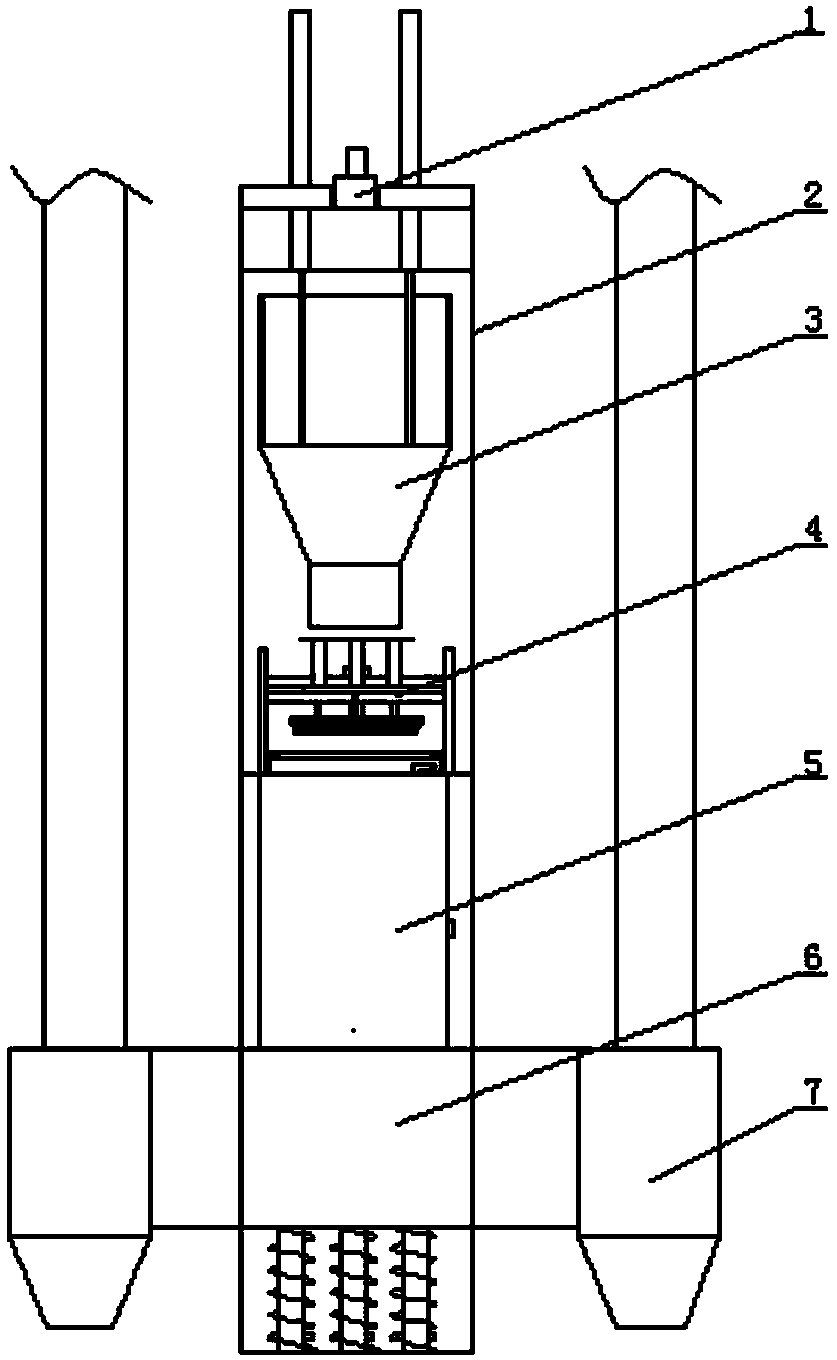

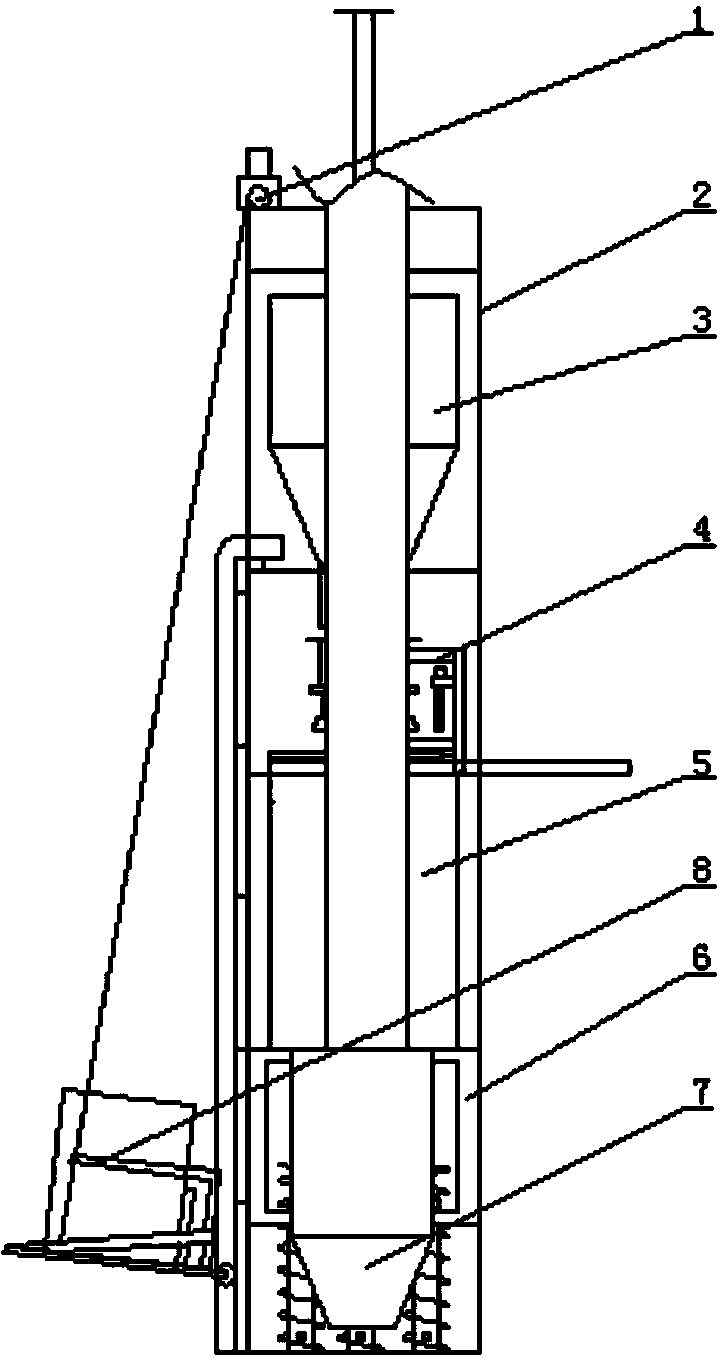

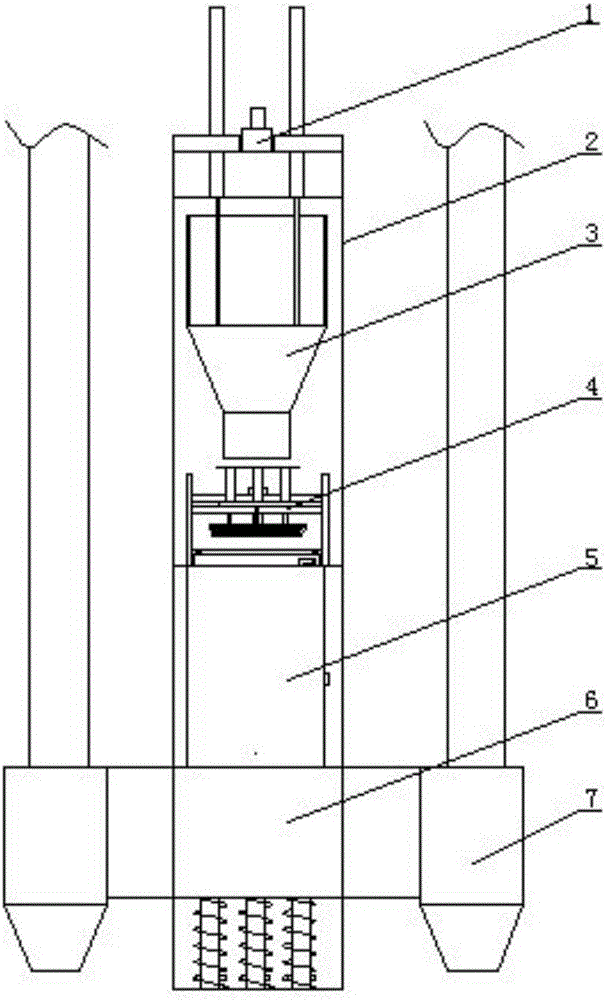

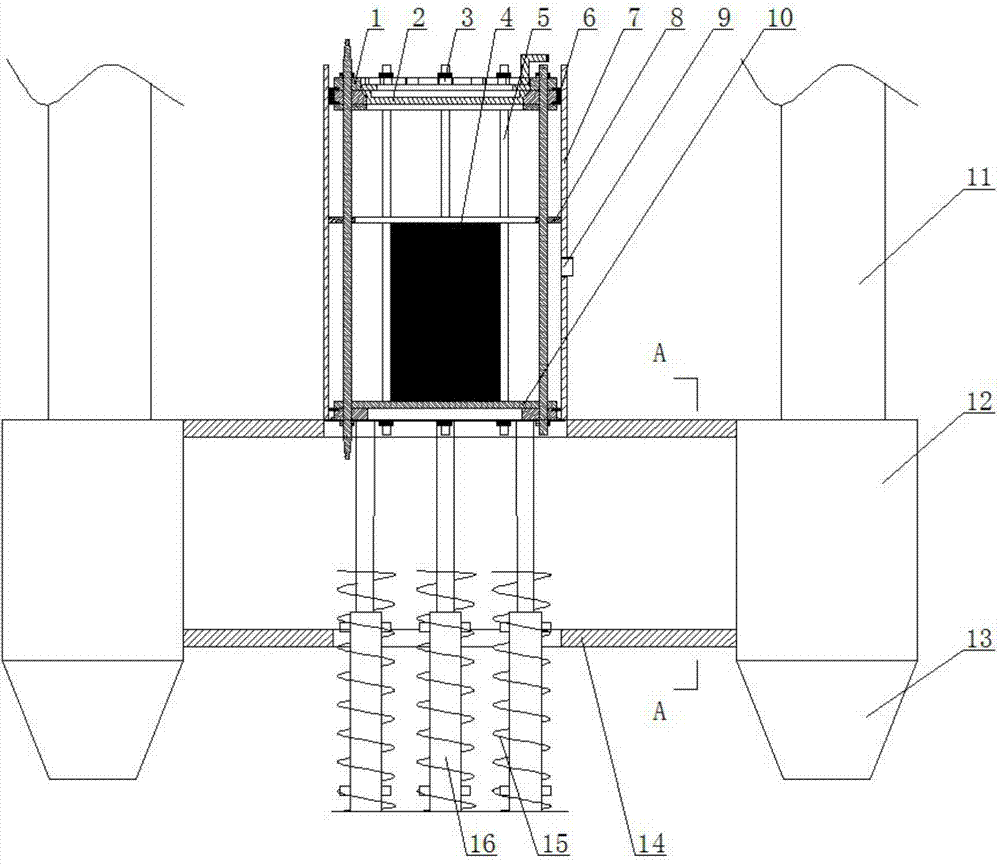

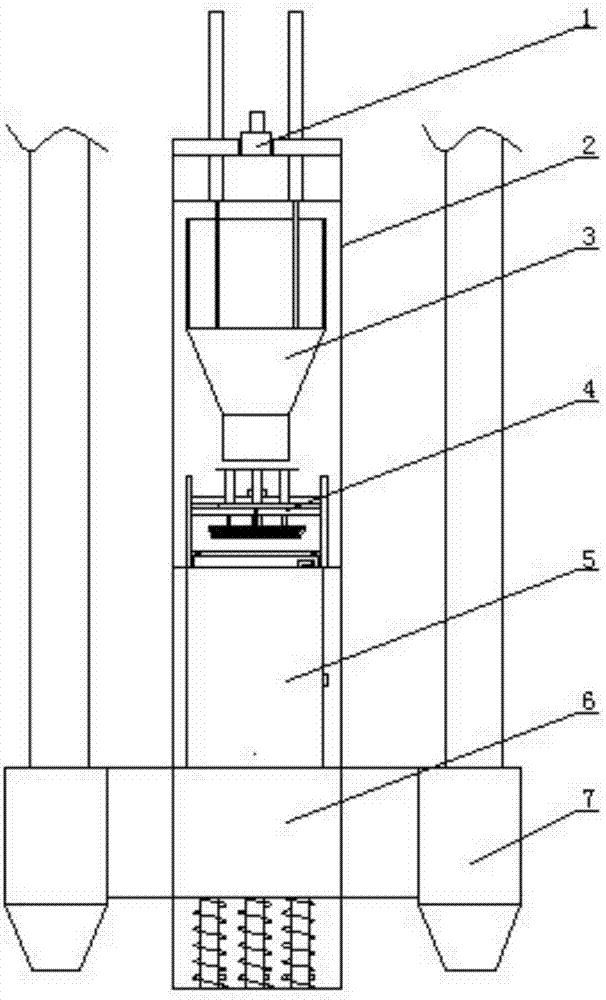

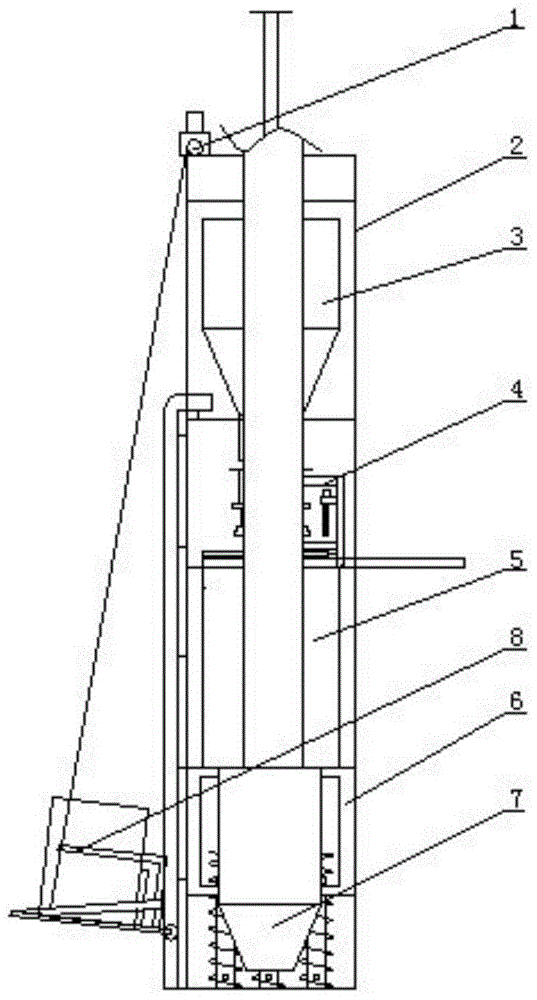

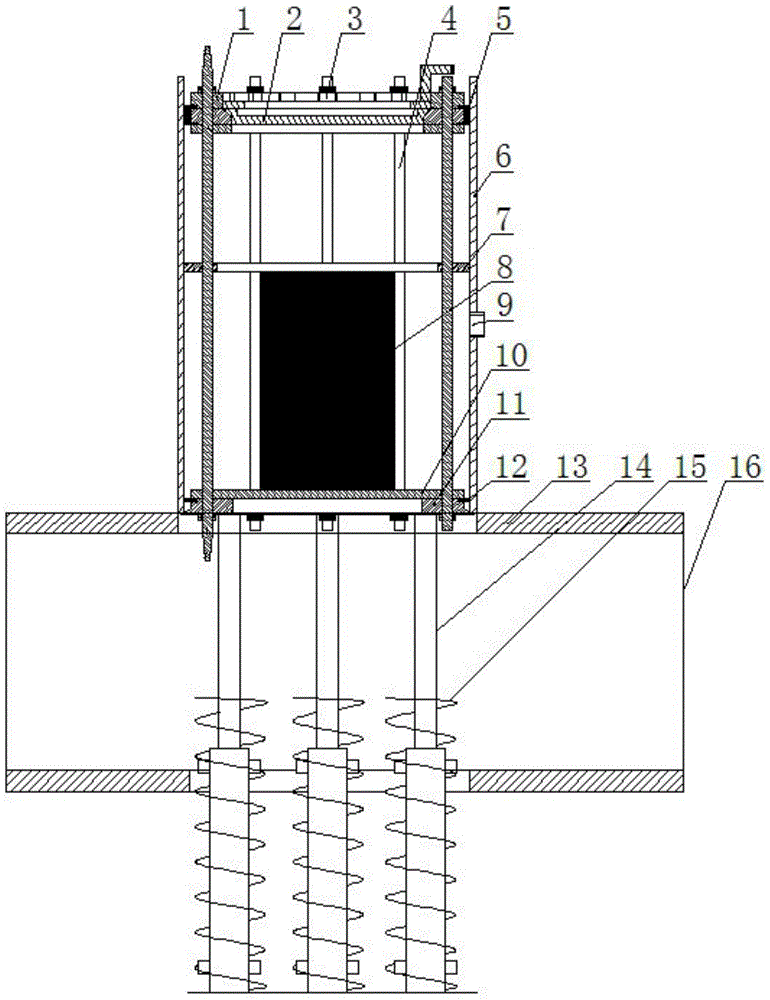

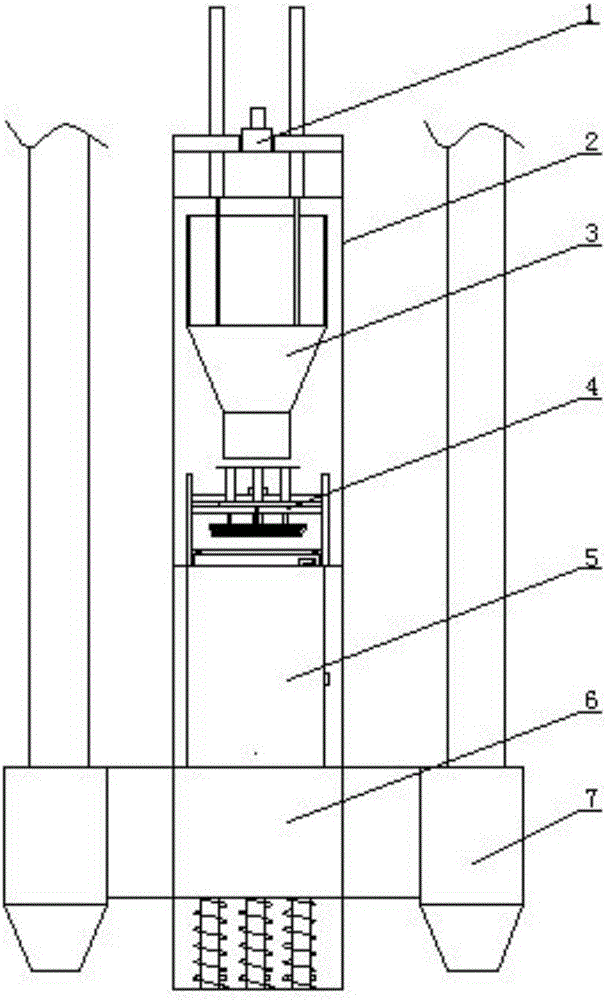

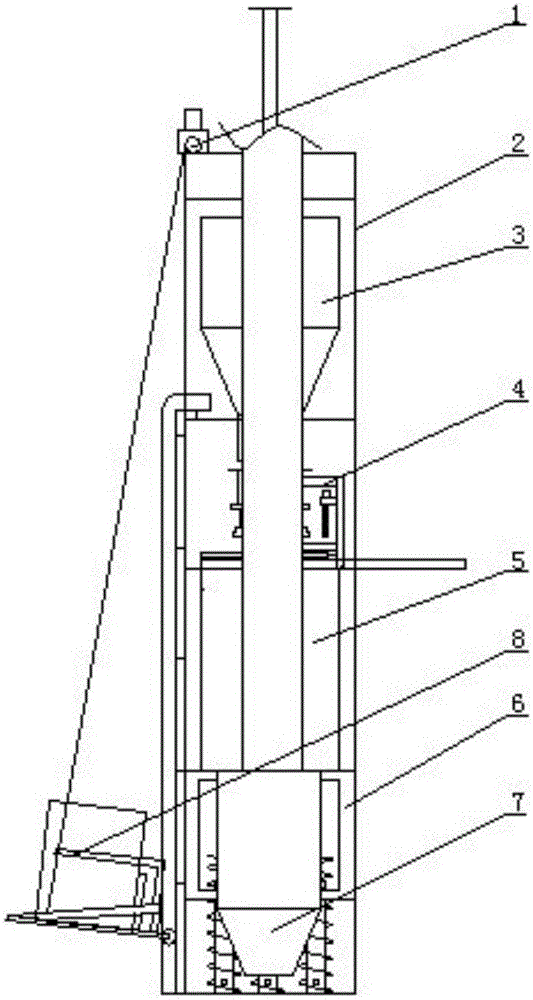

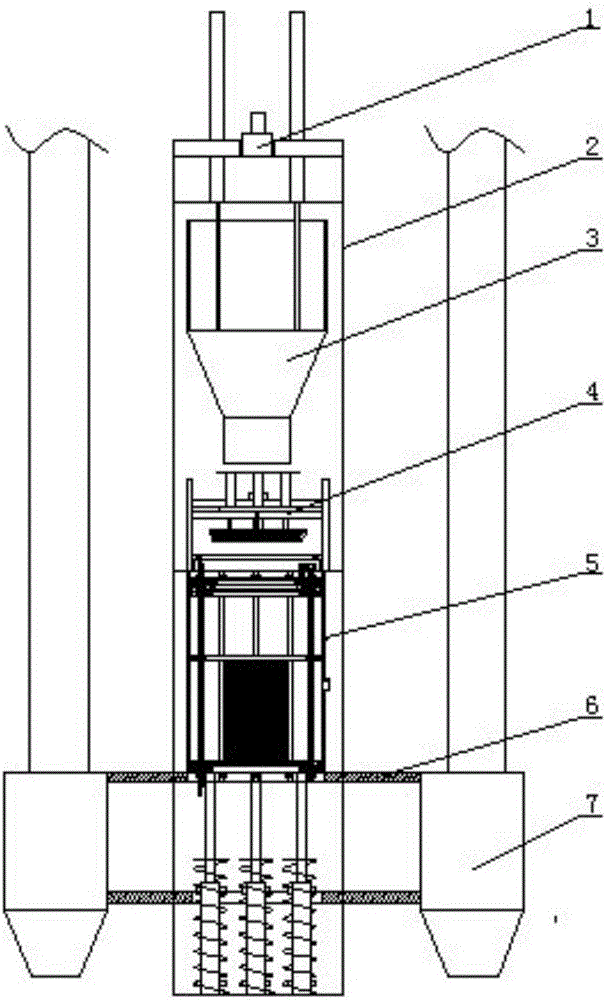

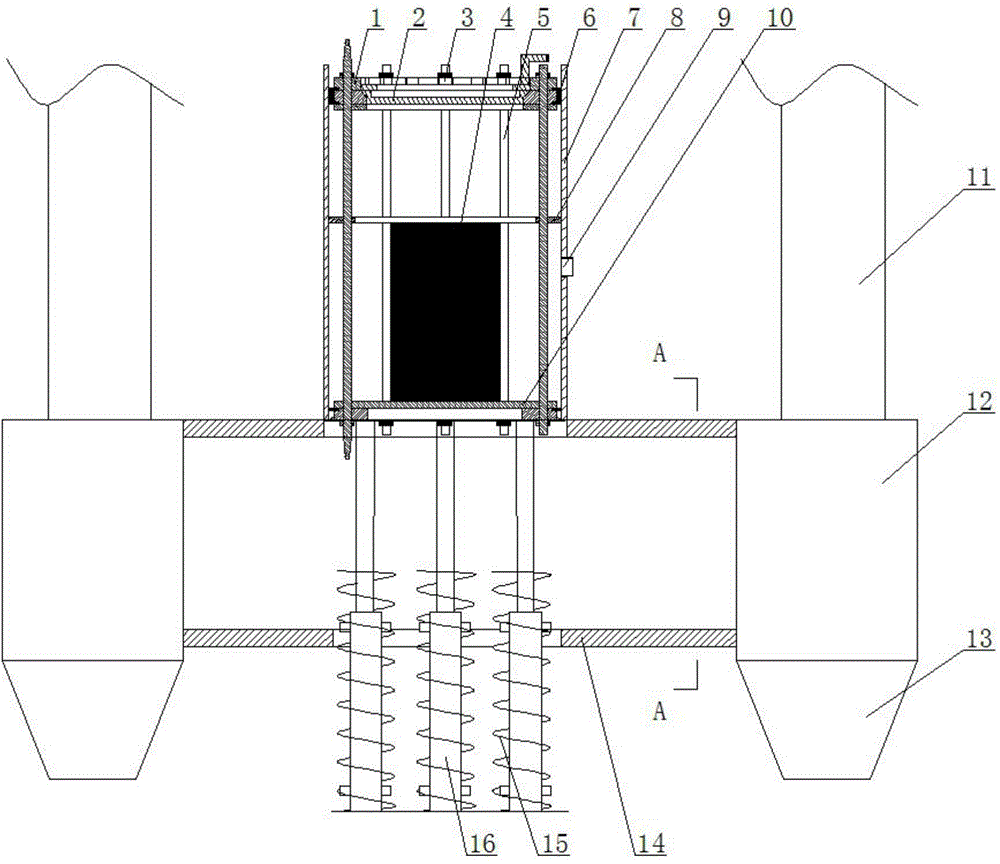

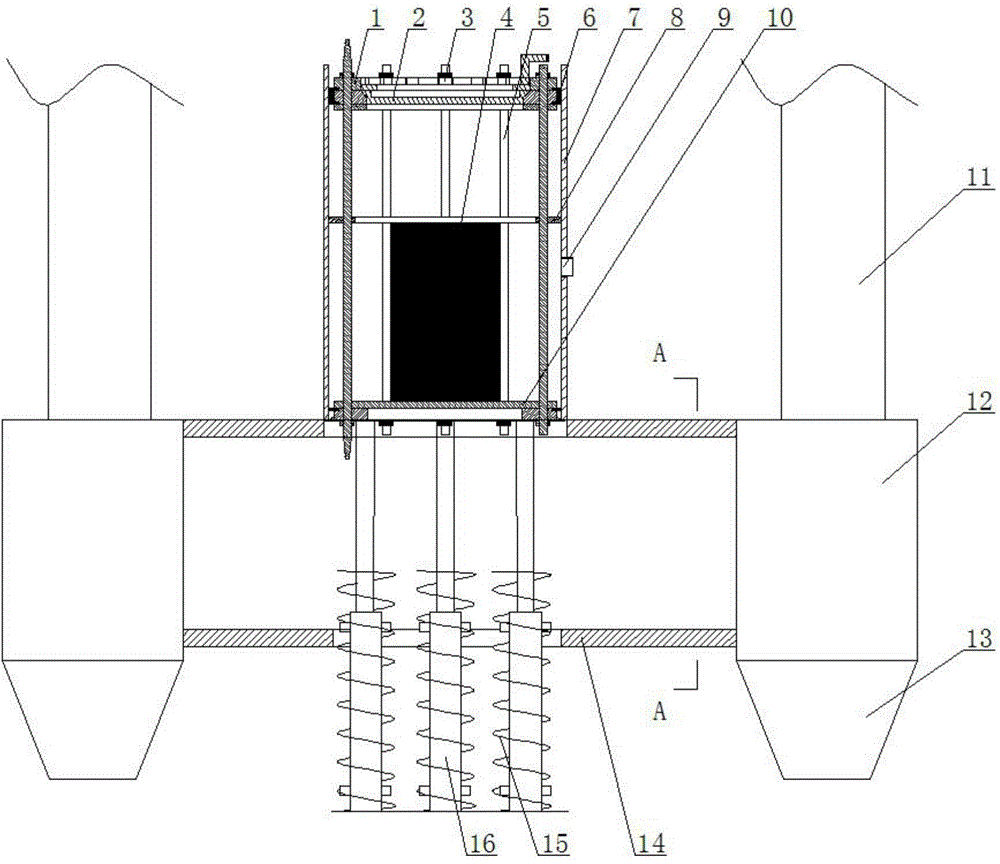

Steam-catapulting-type organic matter garbage disposal system

PendingCN103418600AEasy feedingIncrease the feeding speedSolid waste disposalTransportation and packagingSystems designHigh pressure

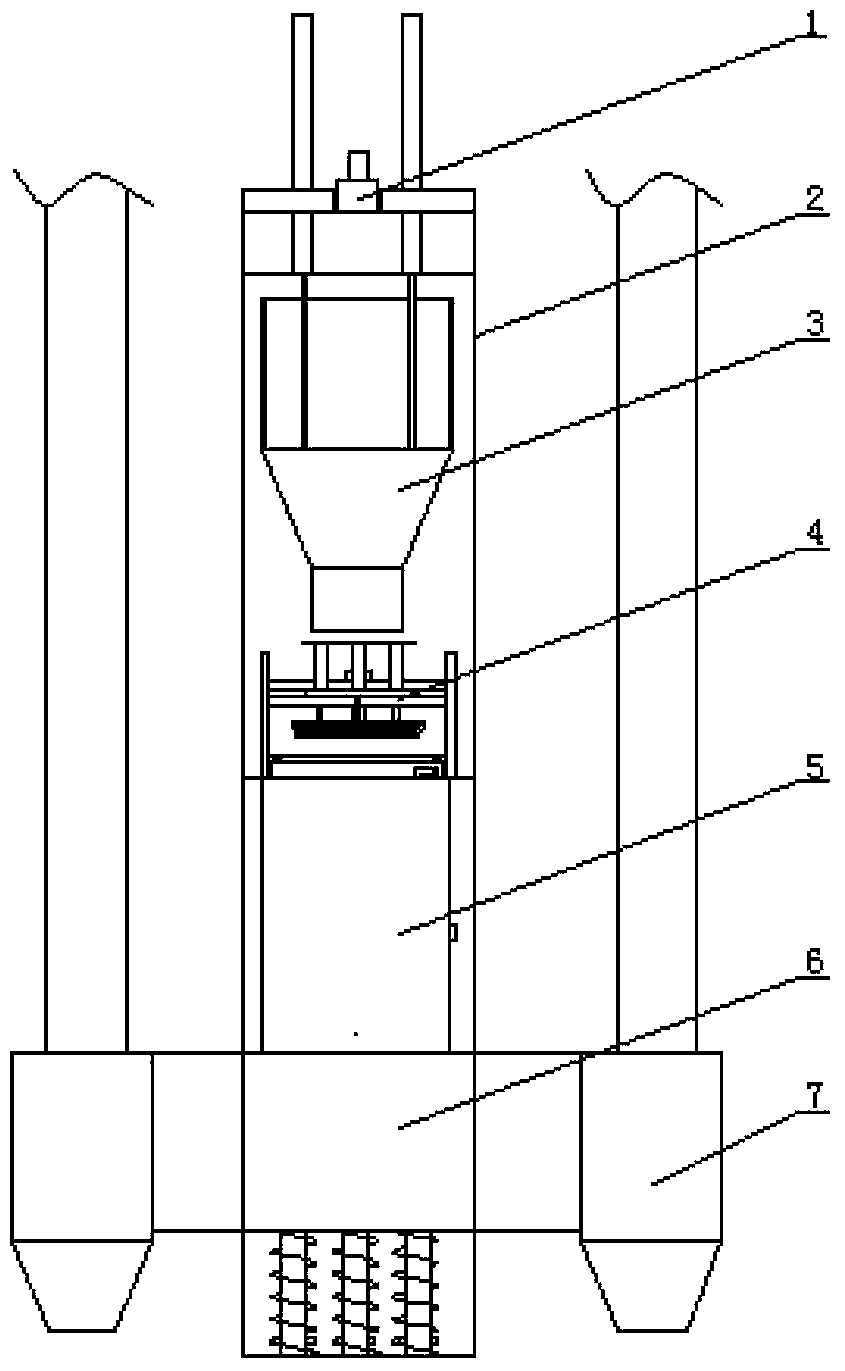

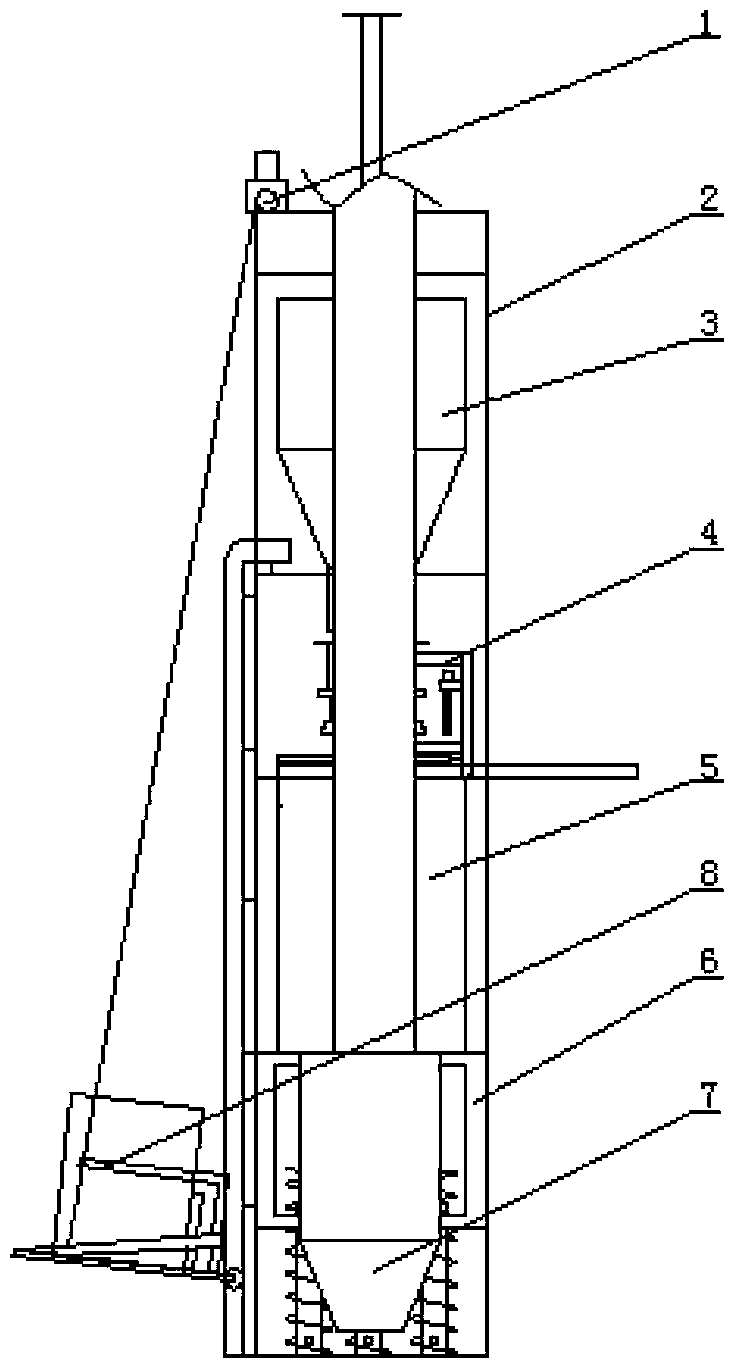

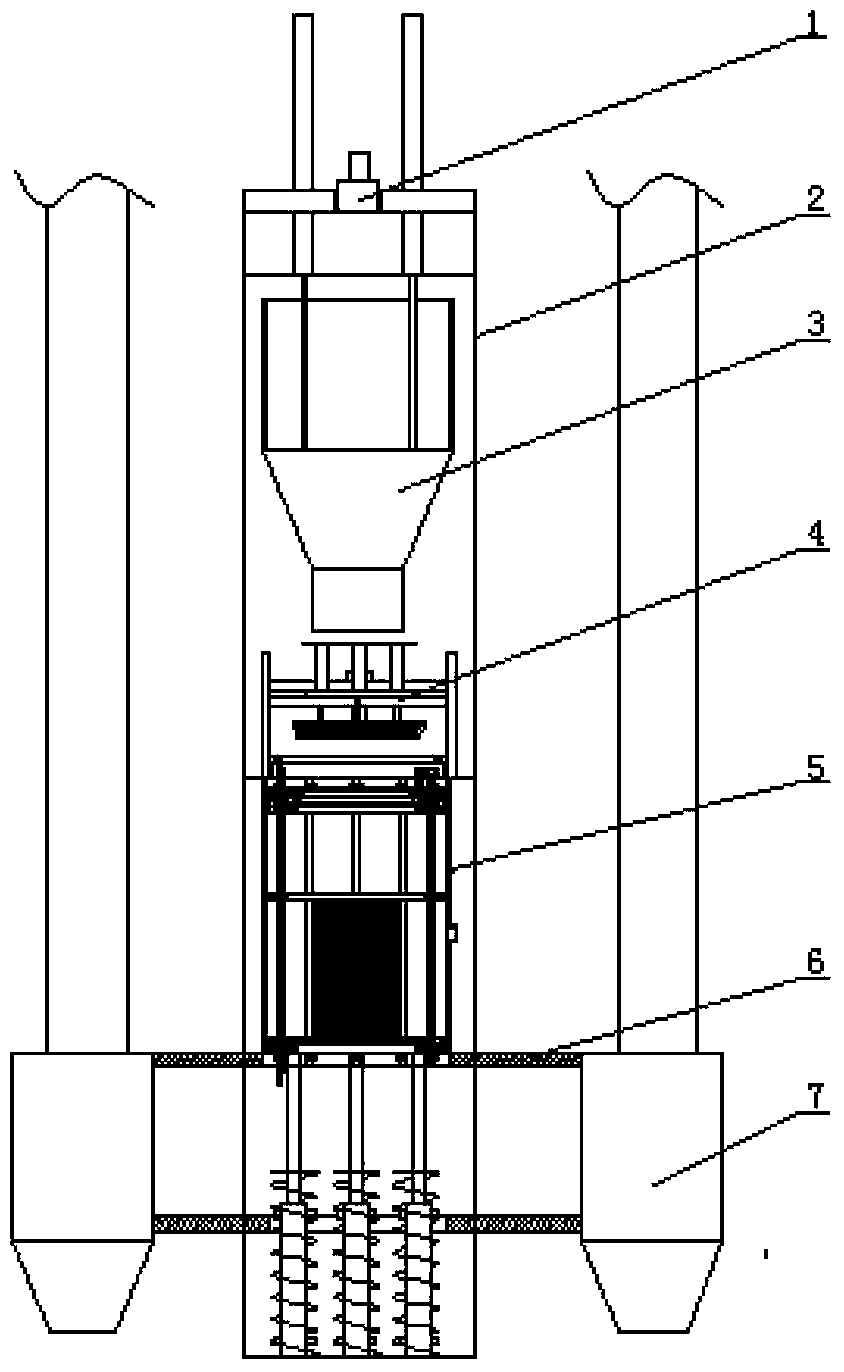

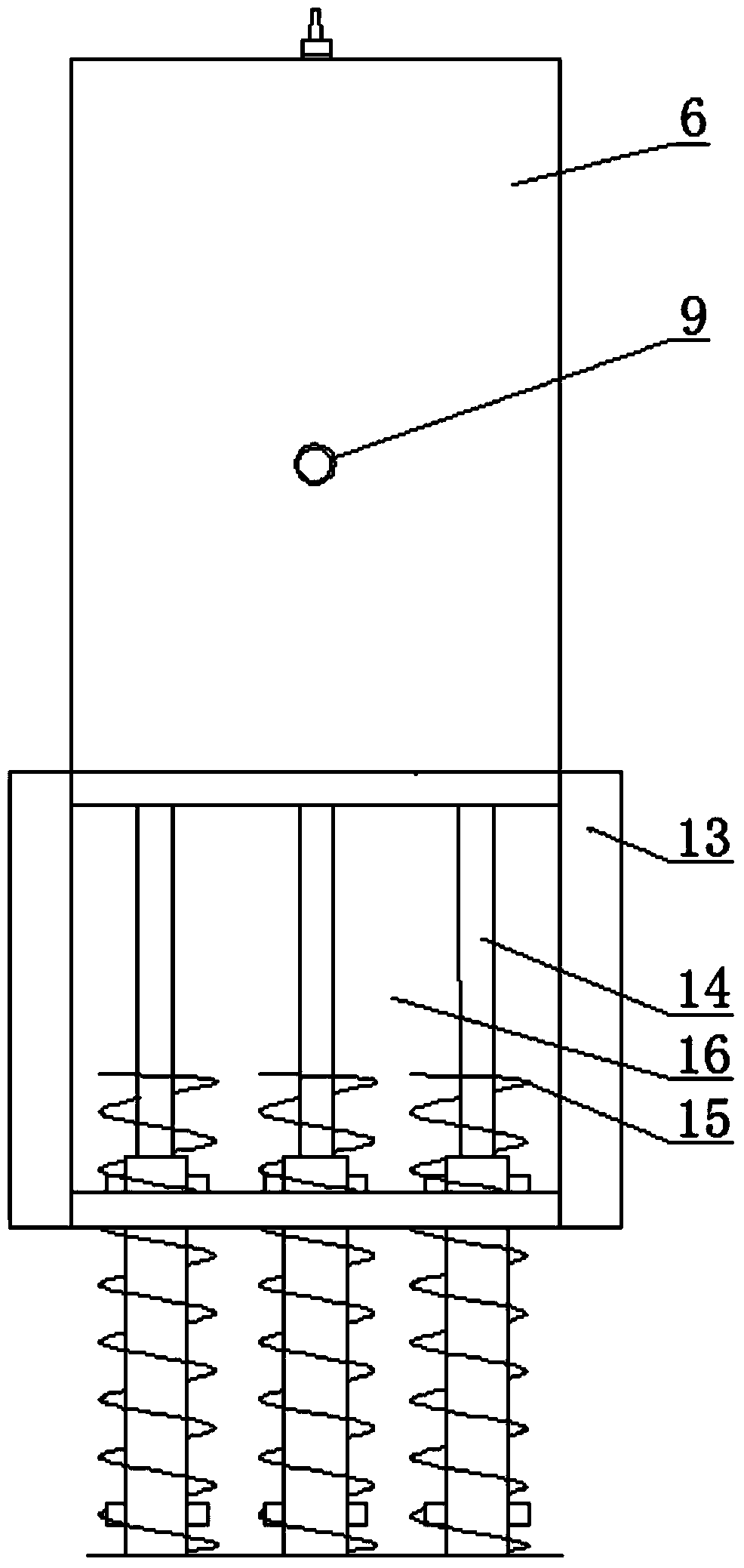

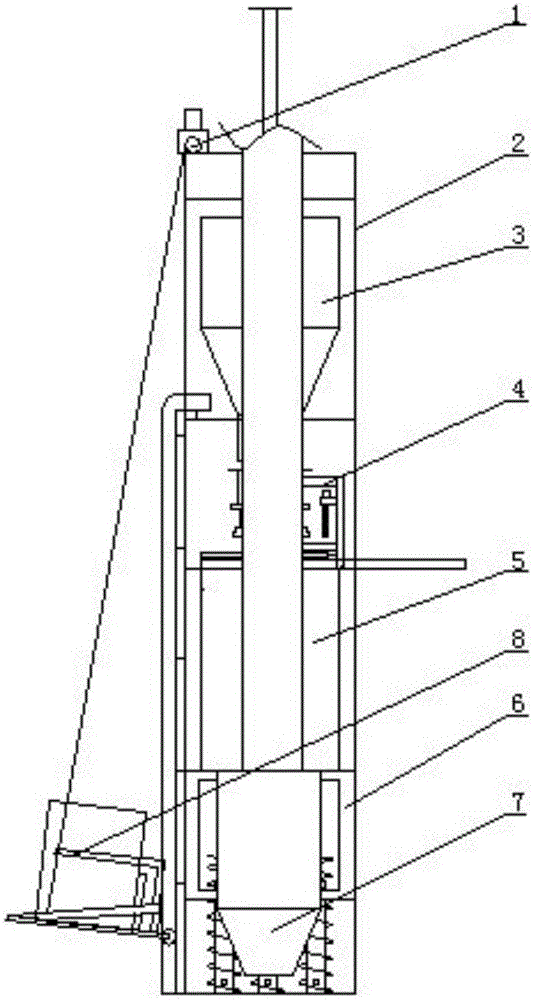

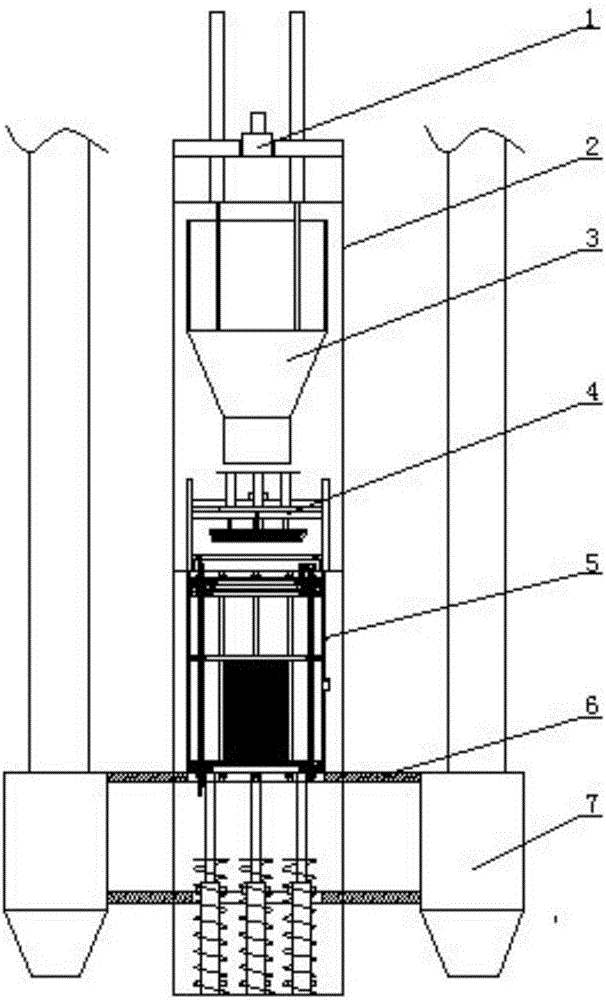

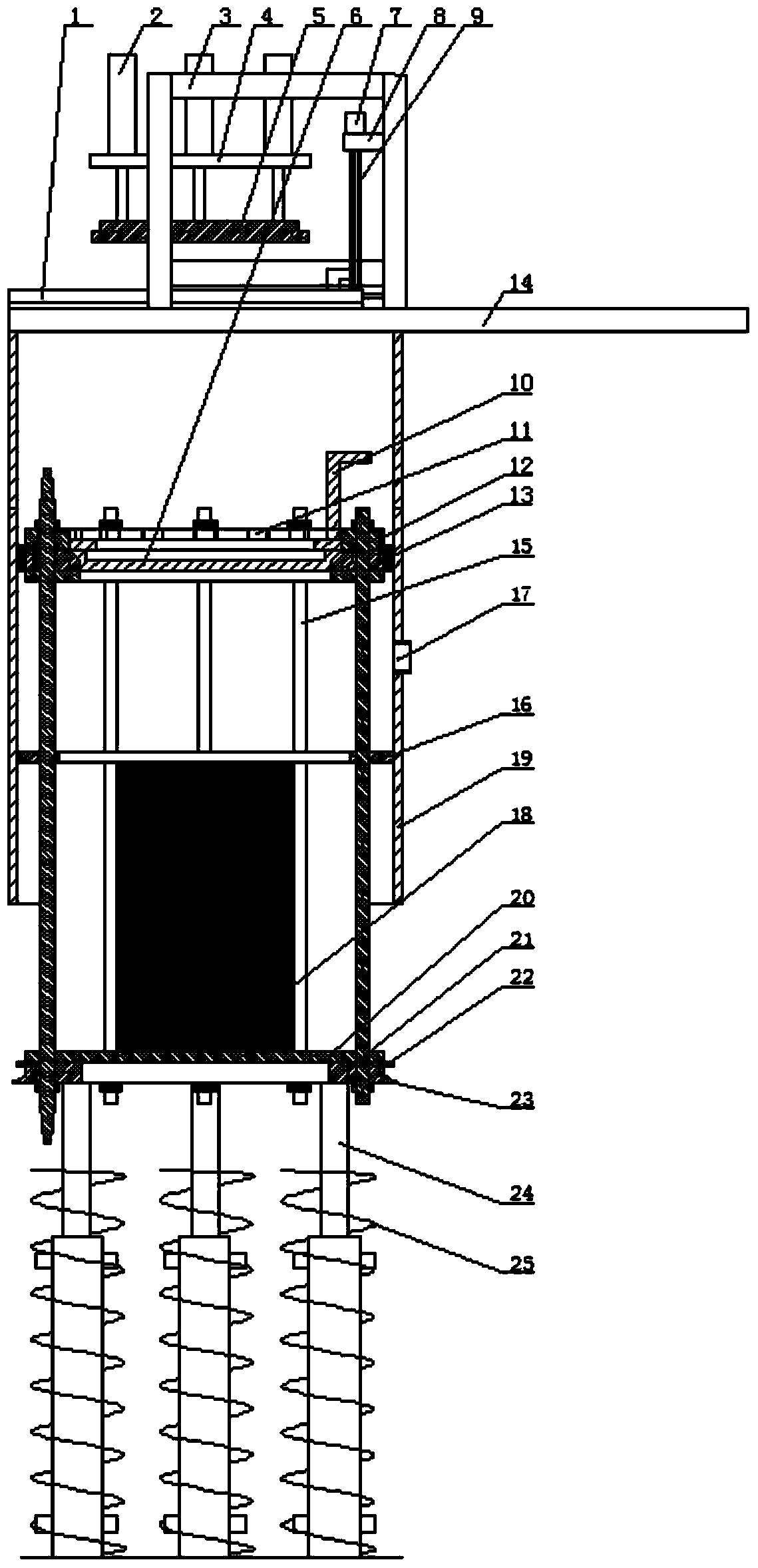

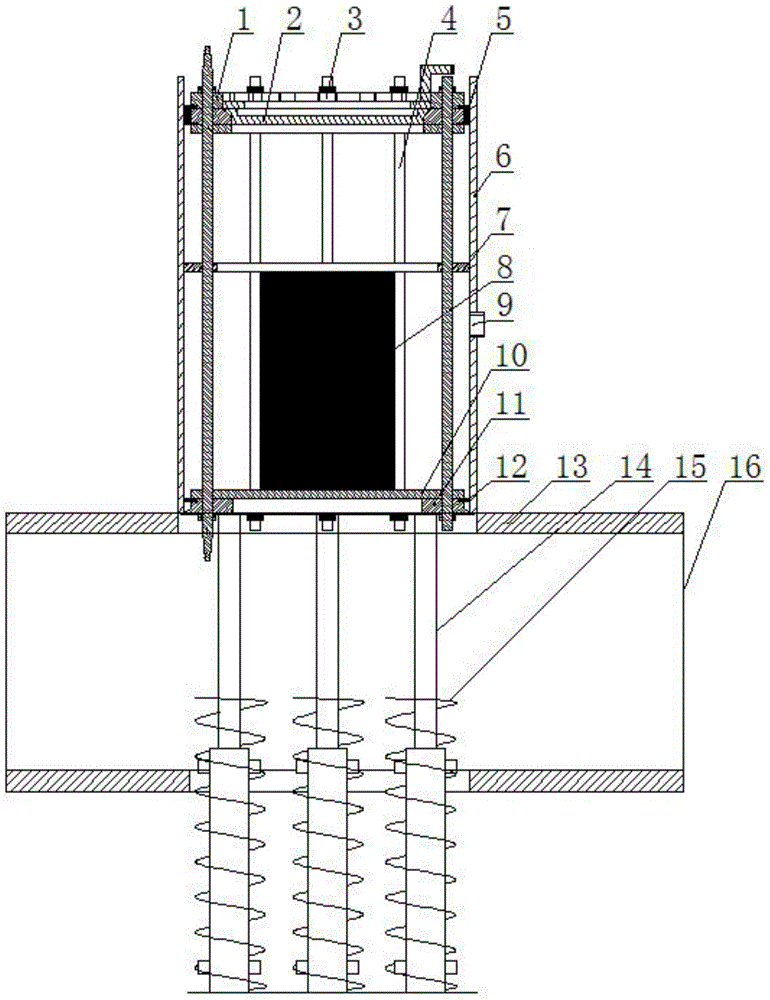

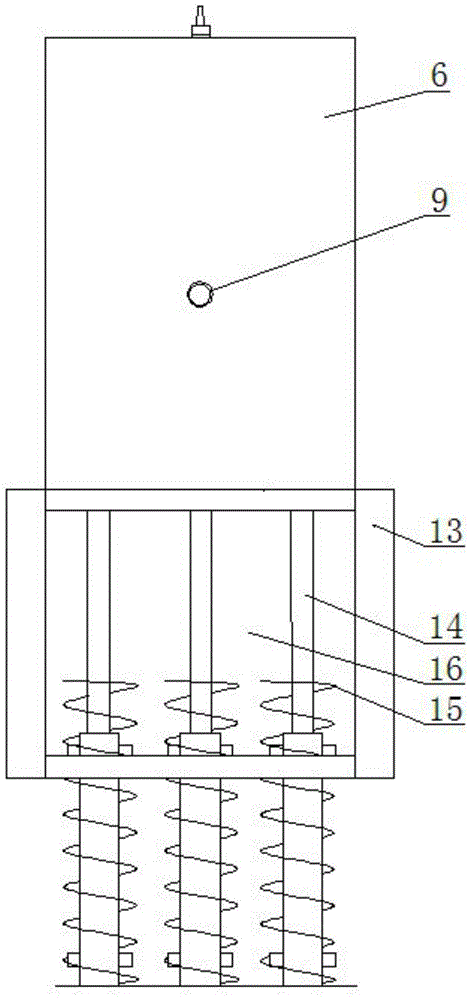

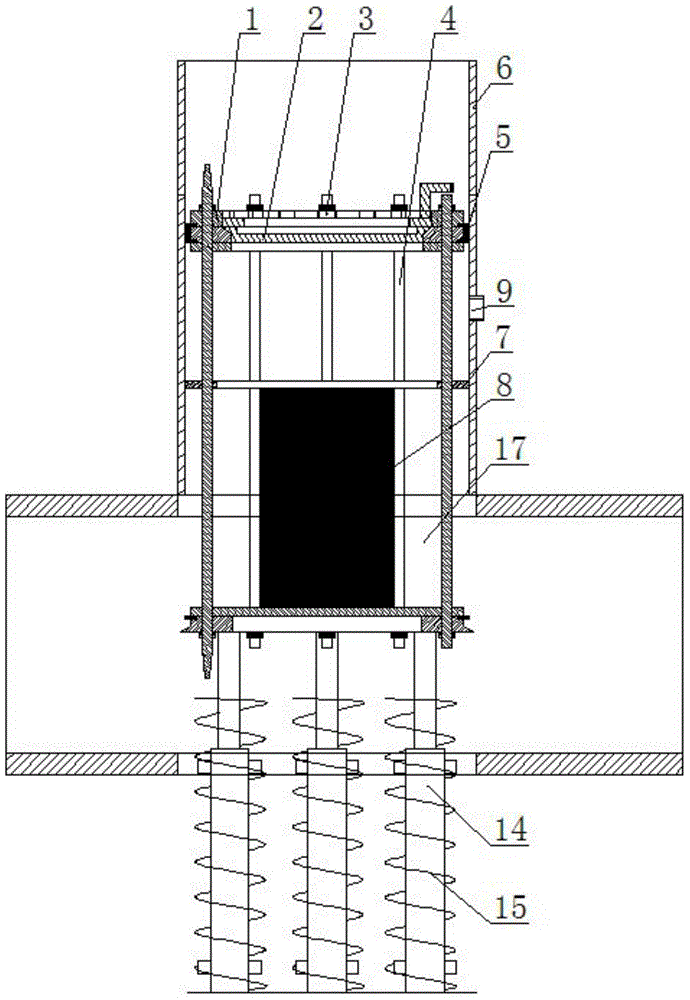

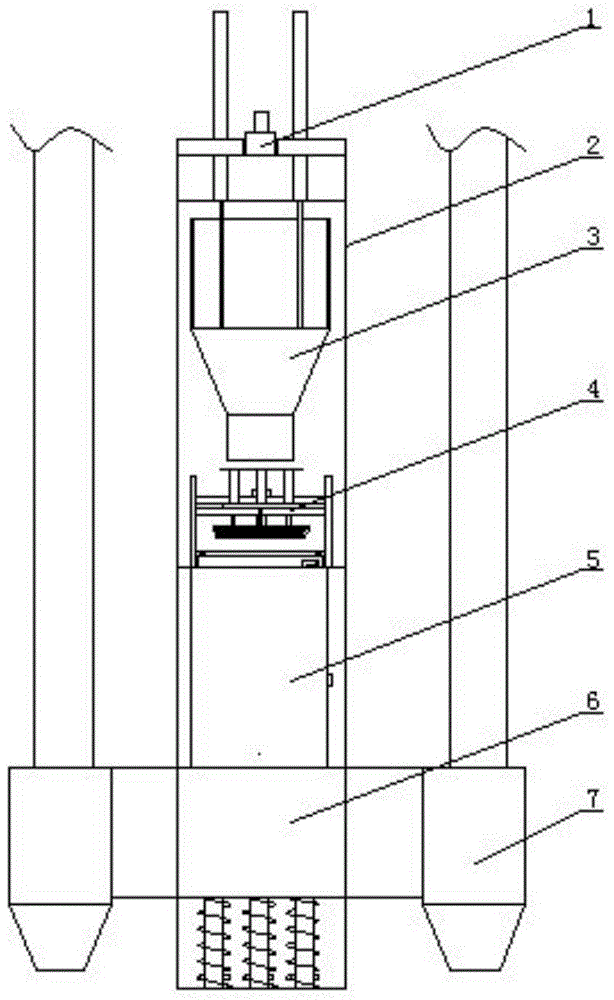

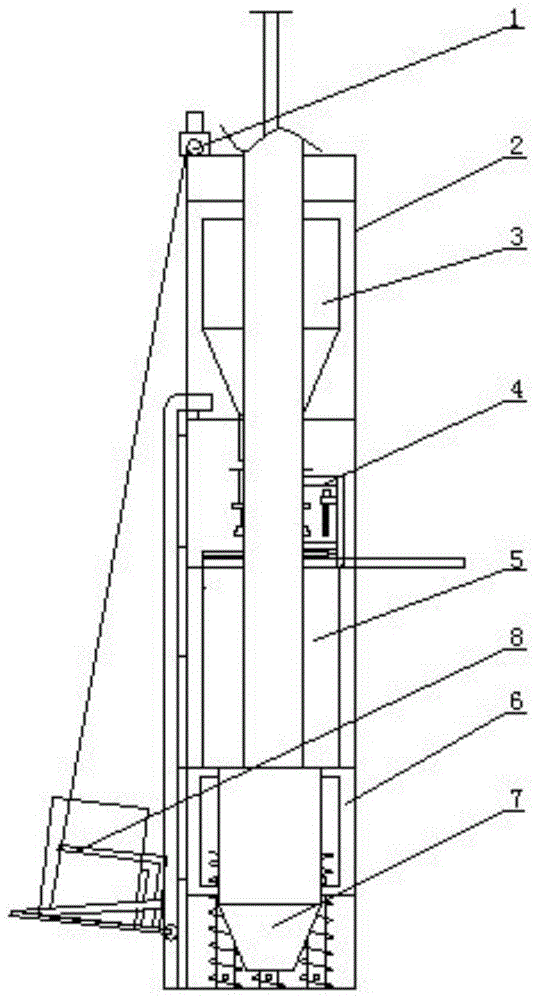

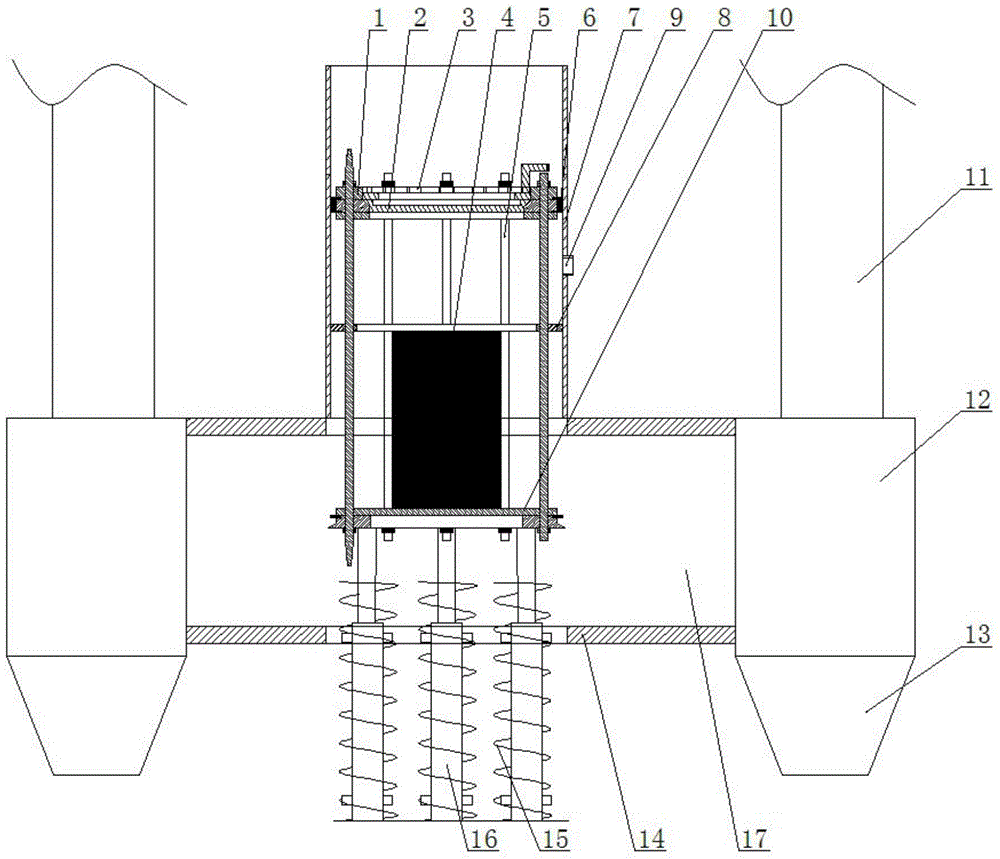

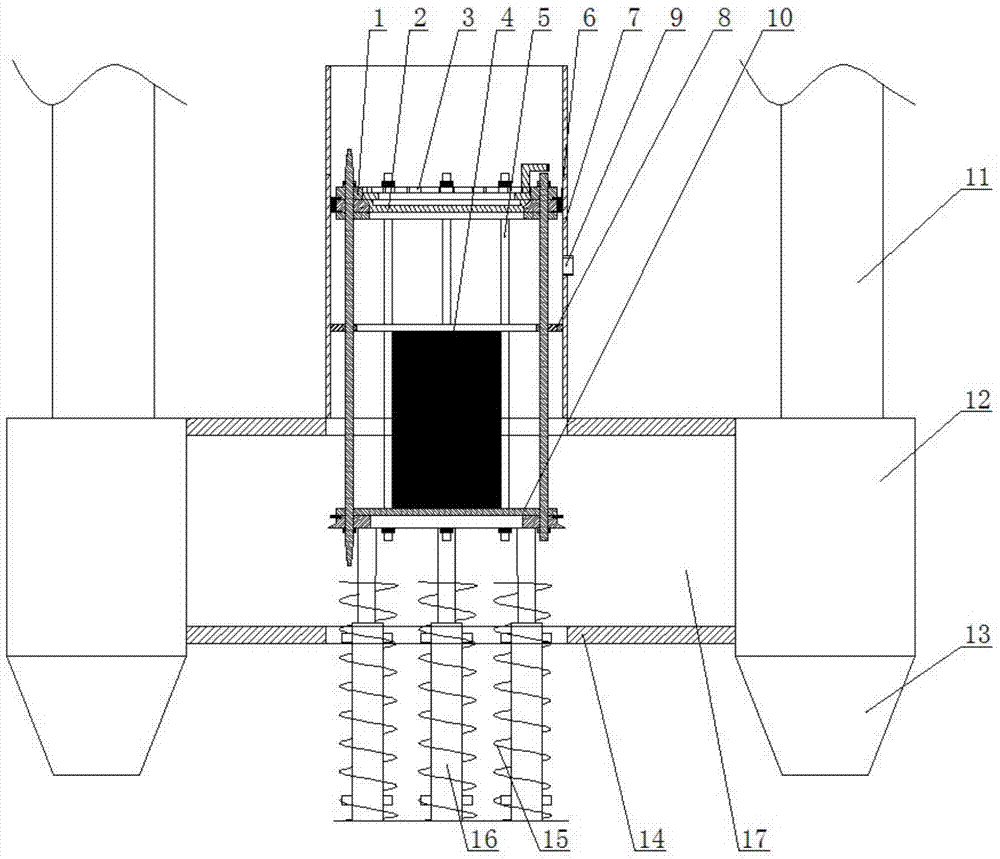

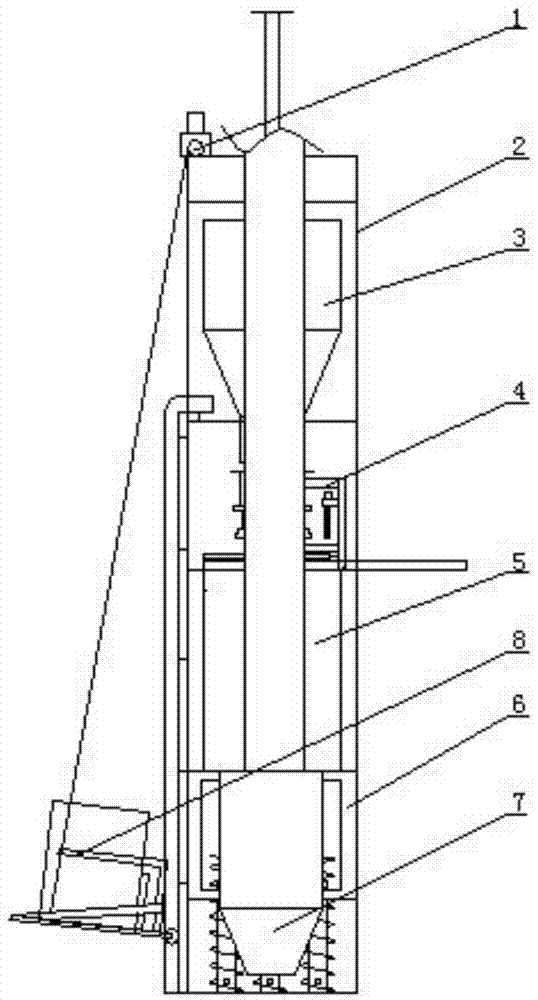

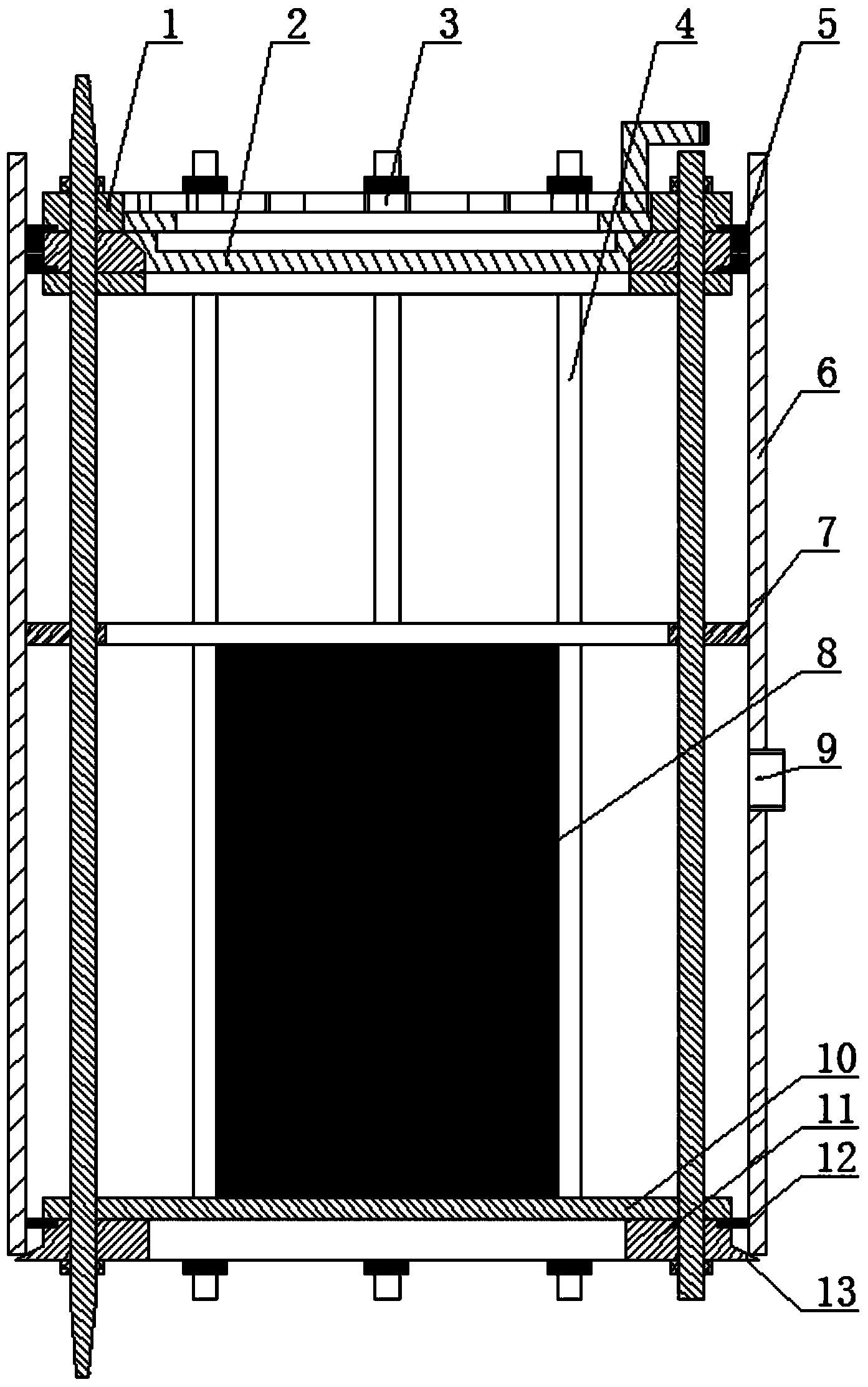

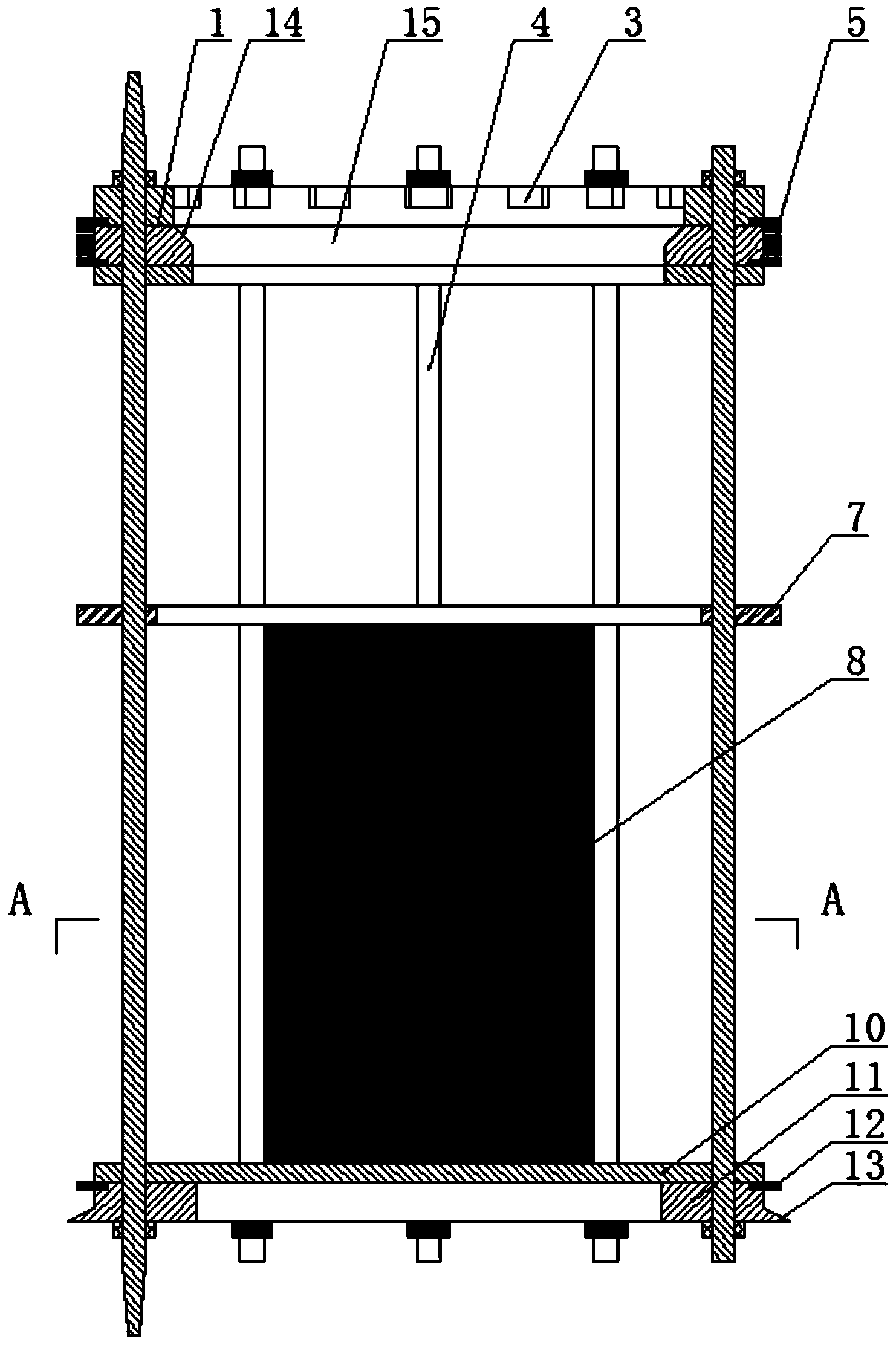

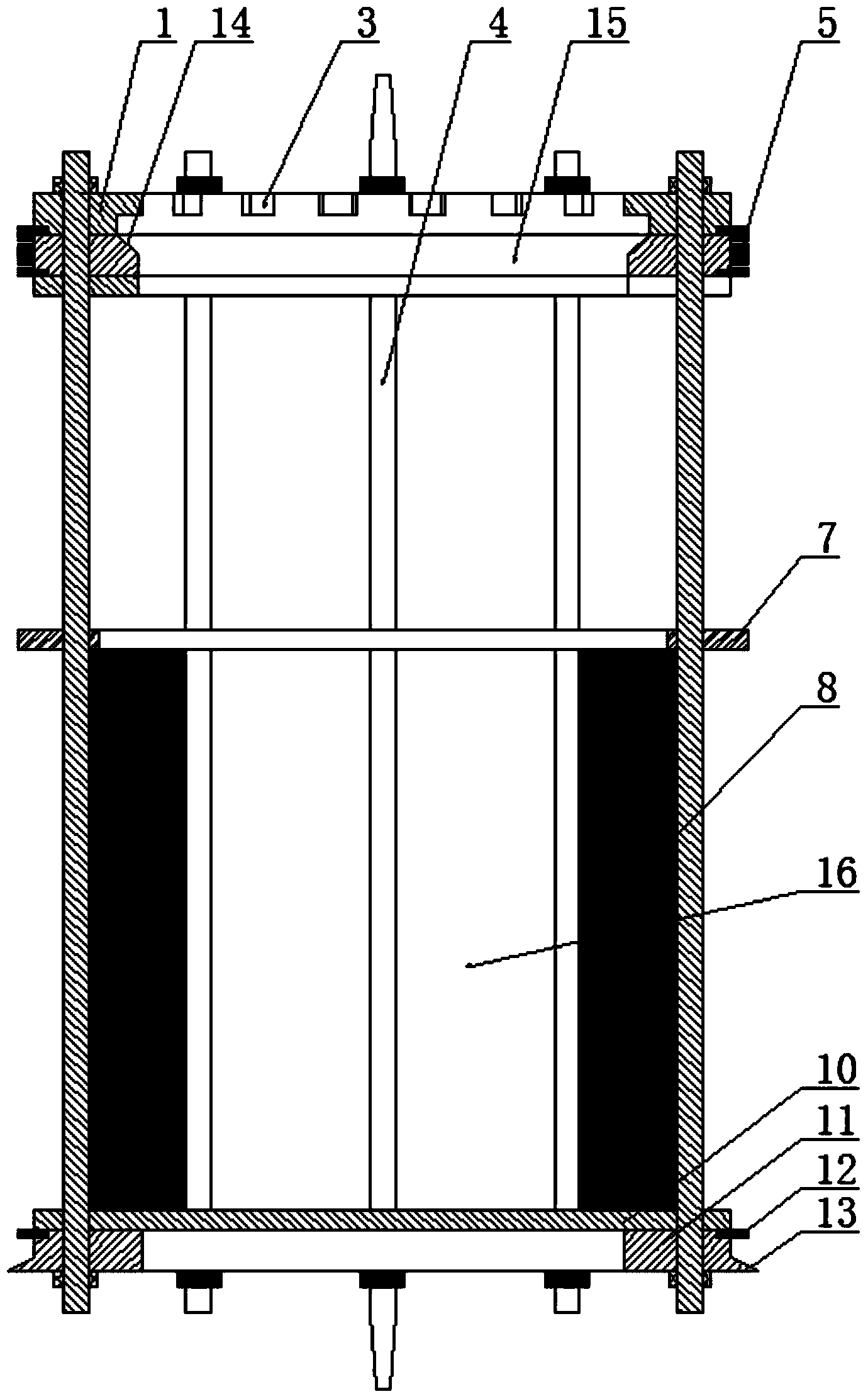

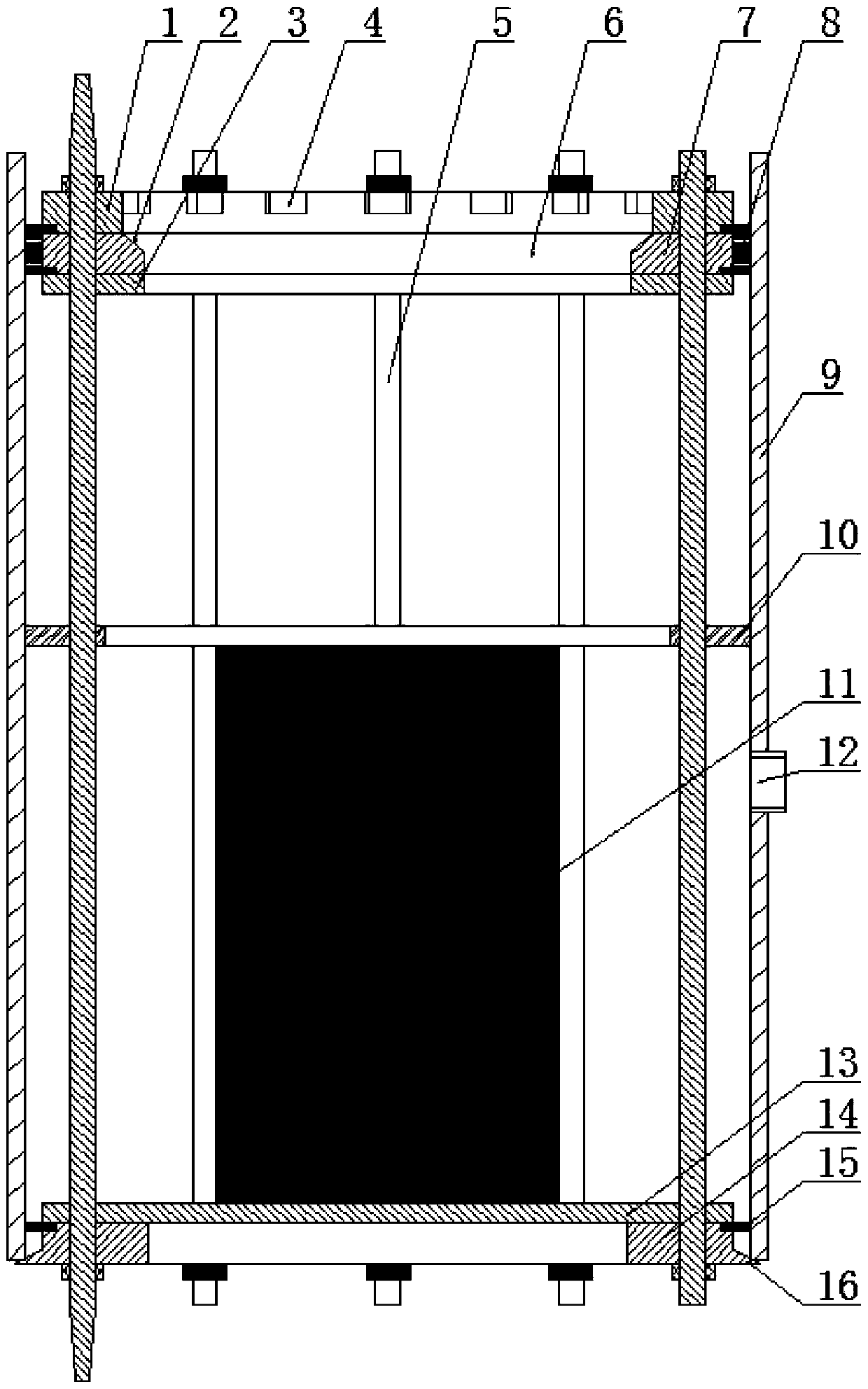

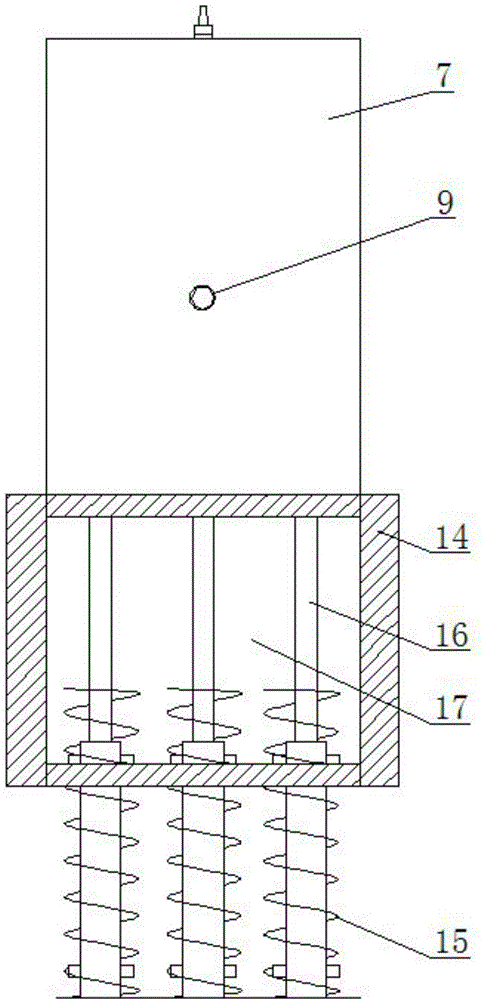

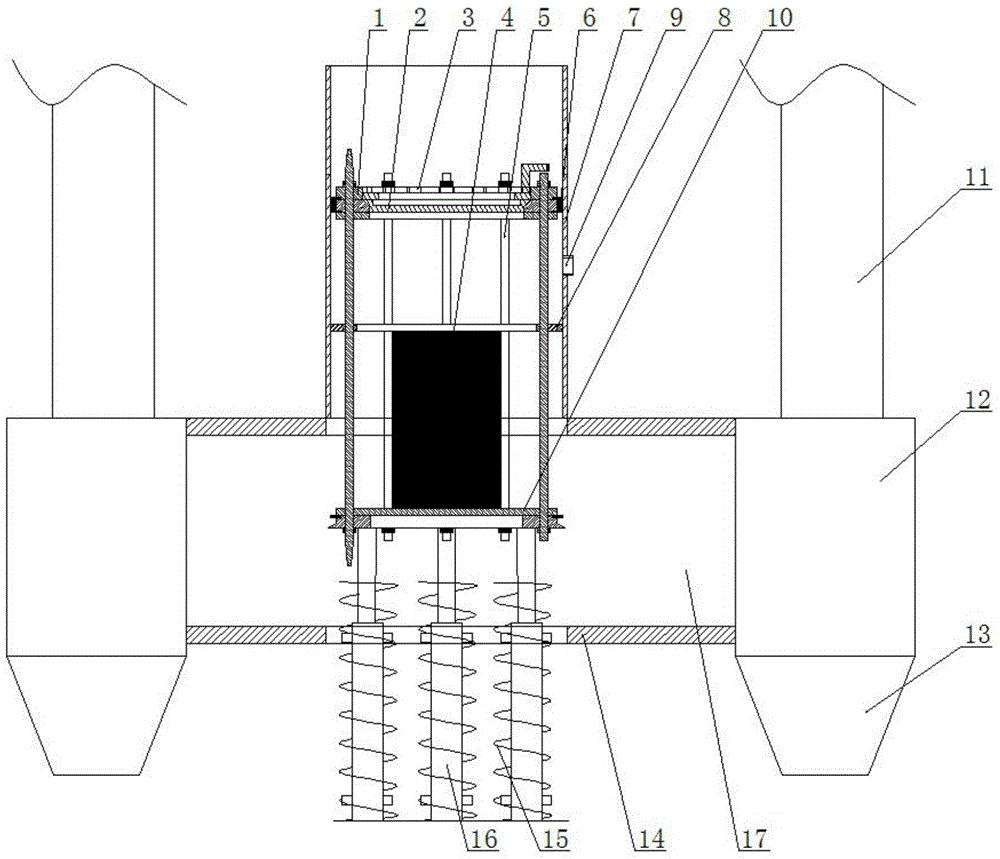

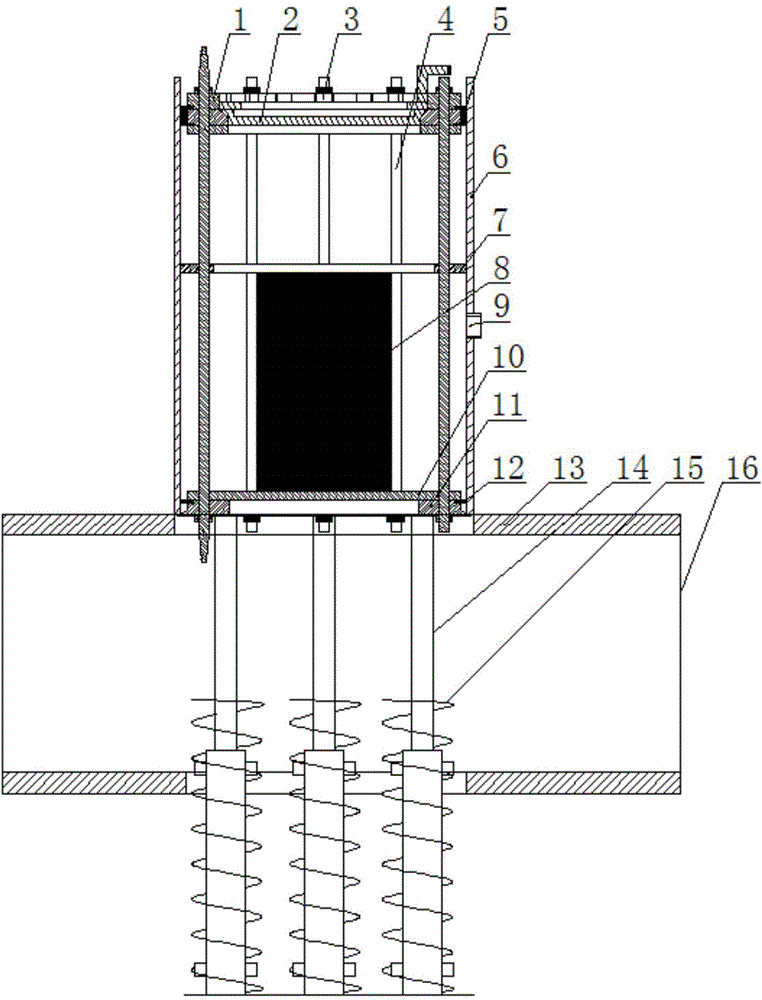

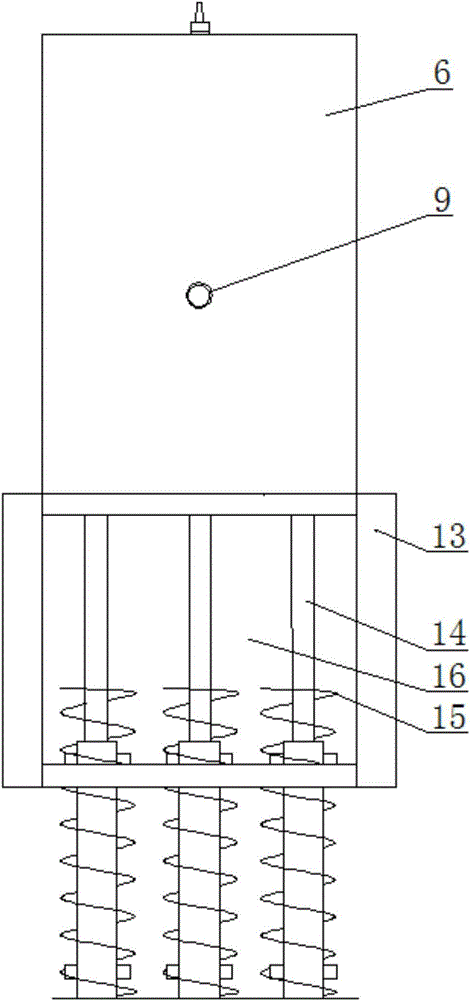

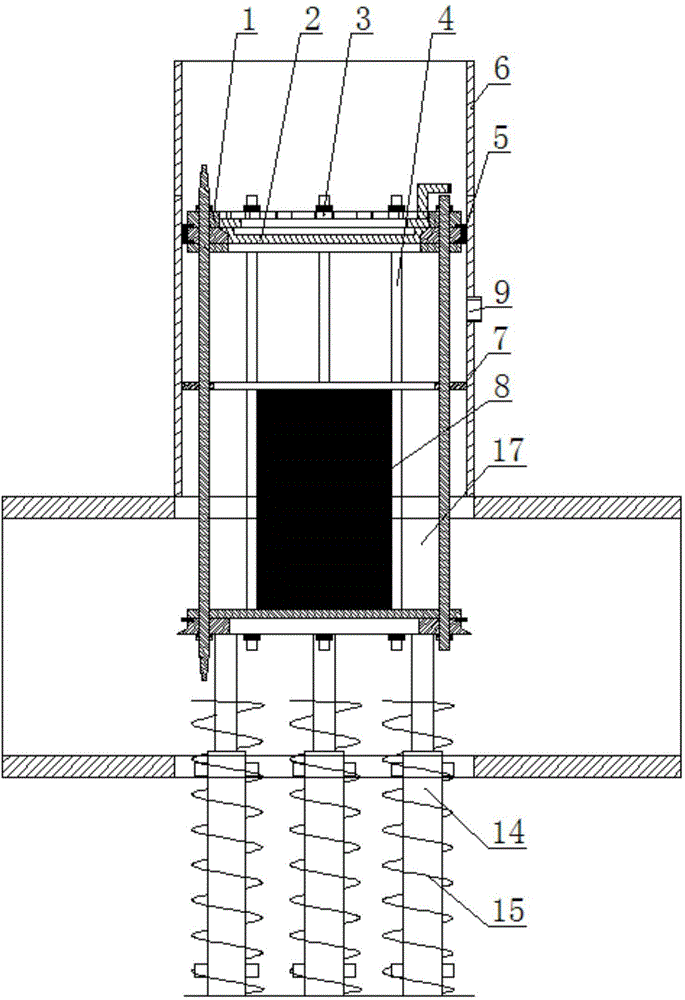

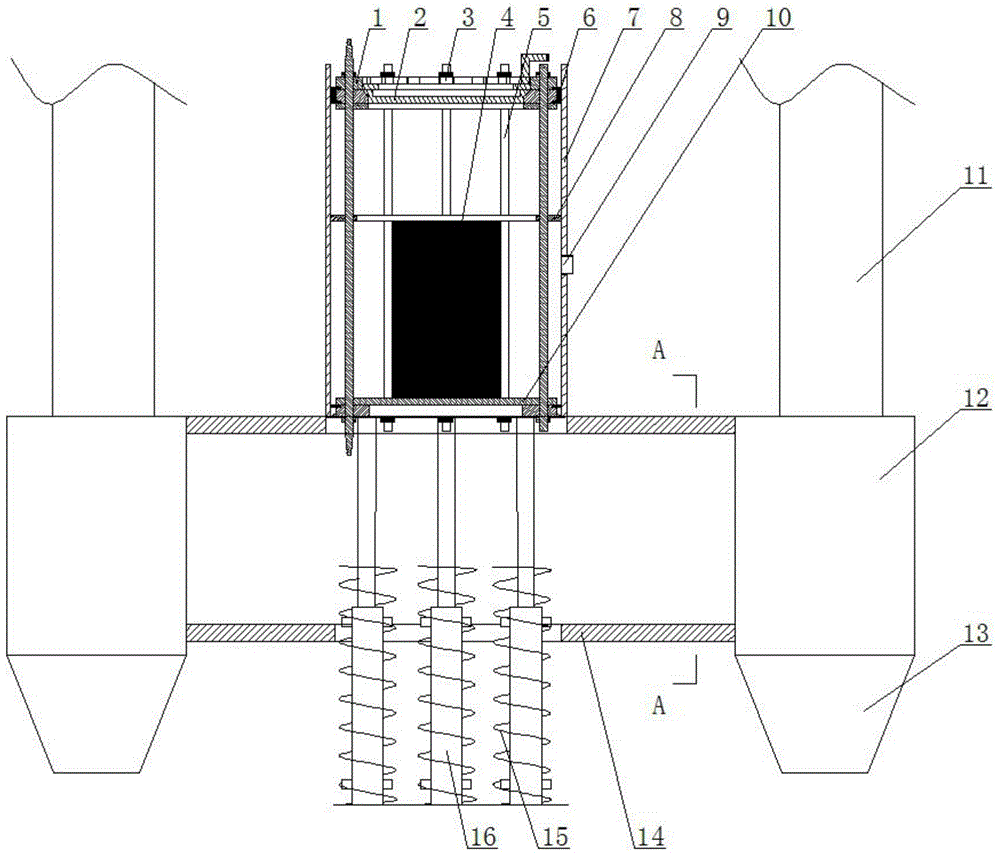

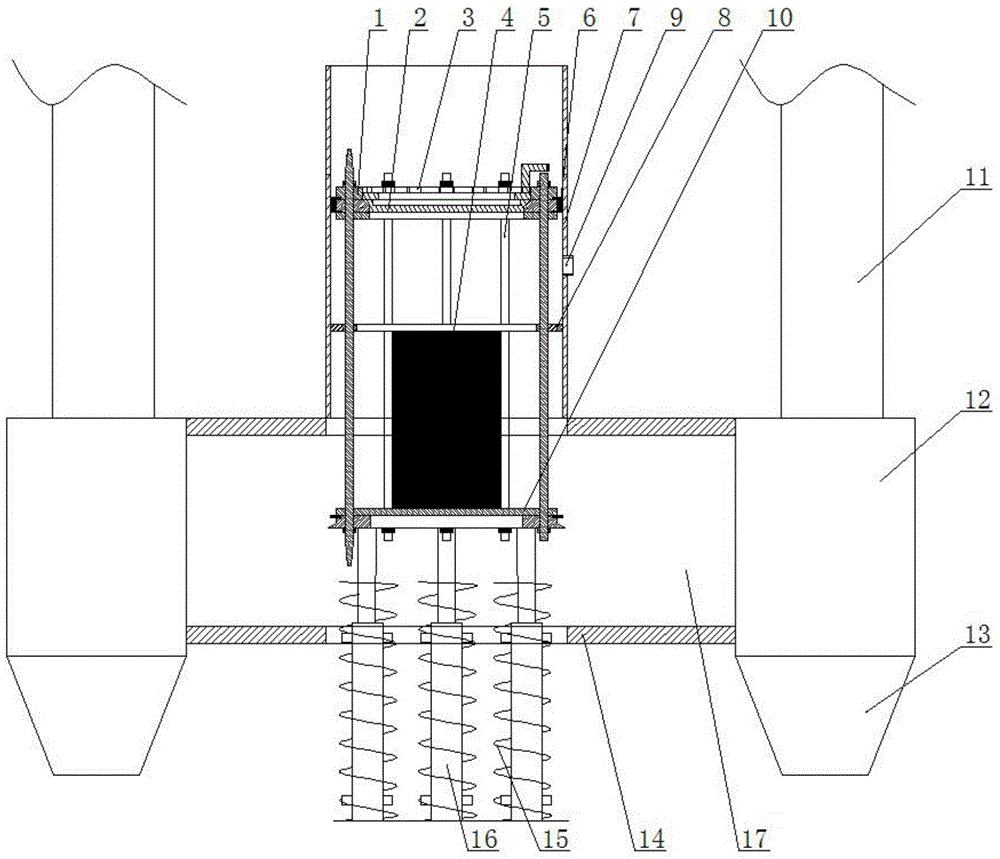

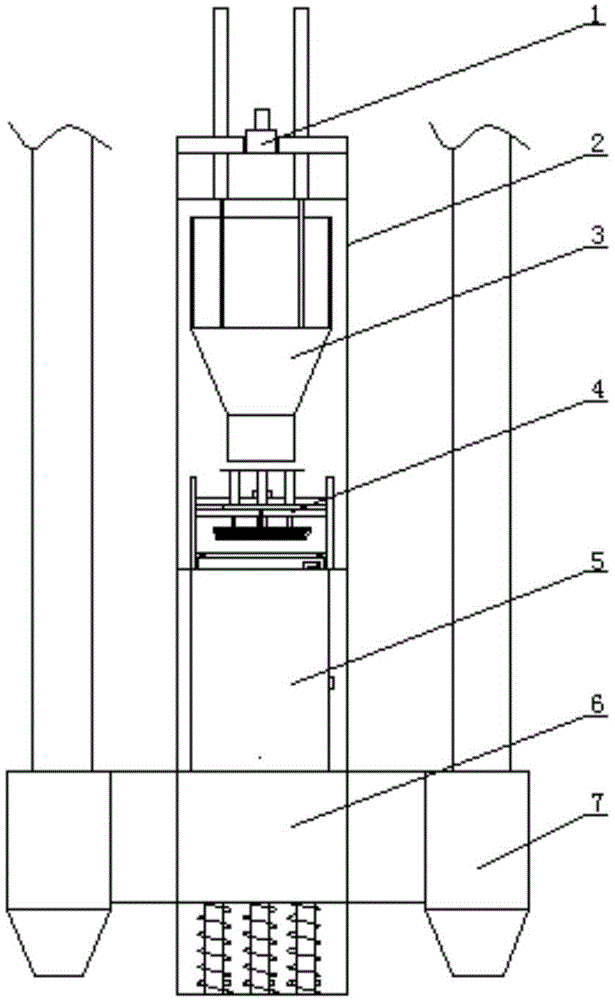

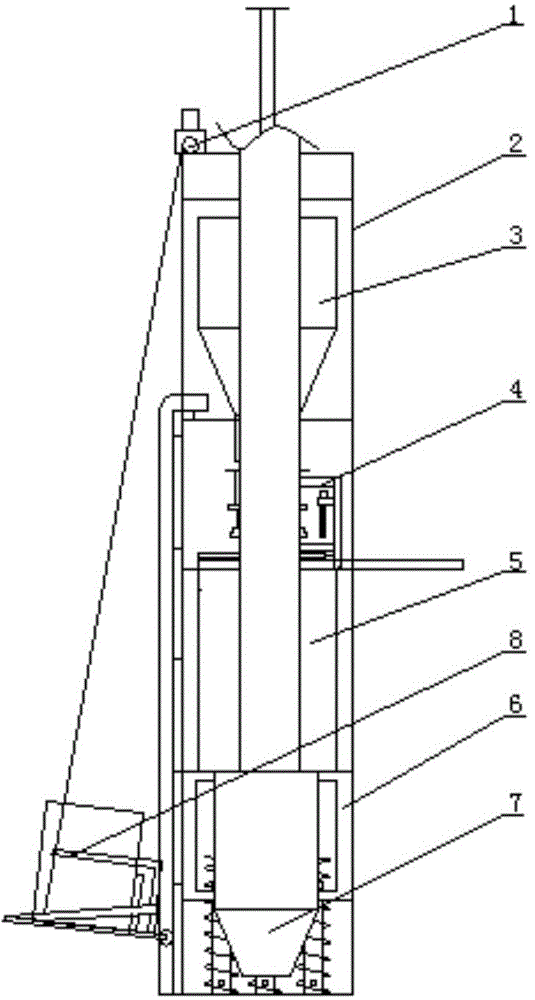

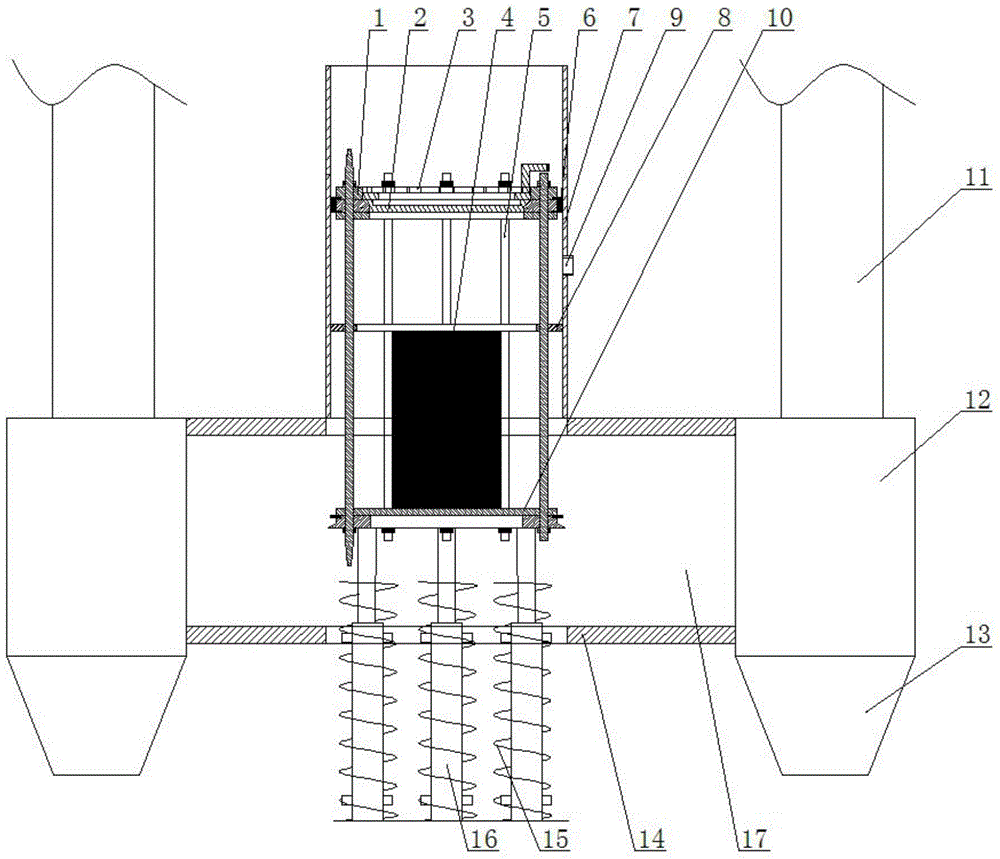

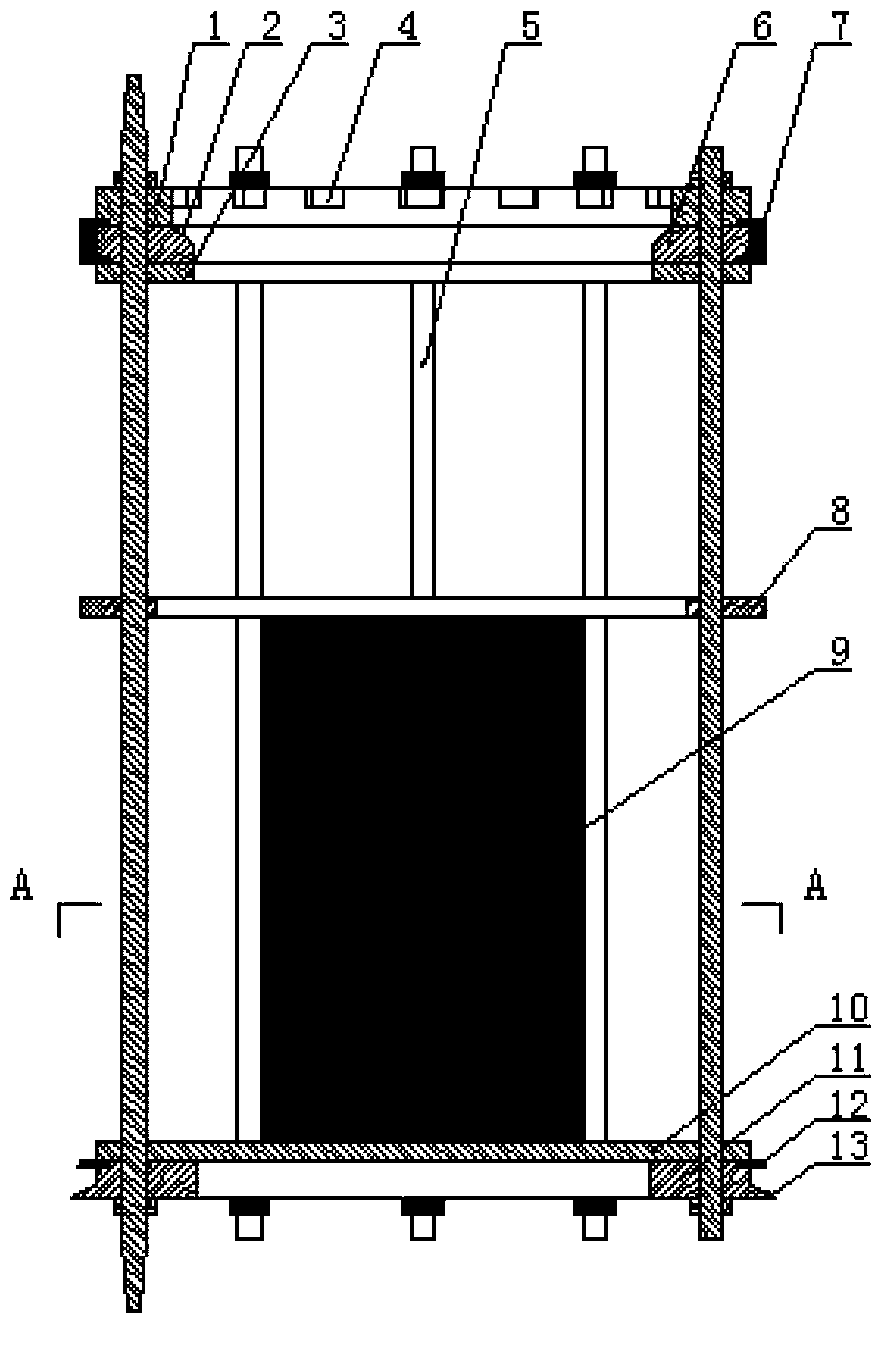

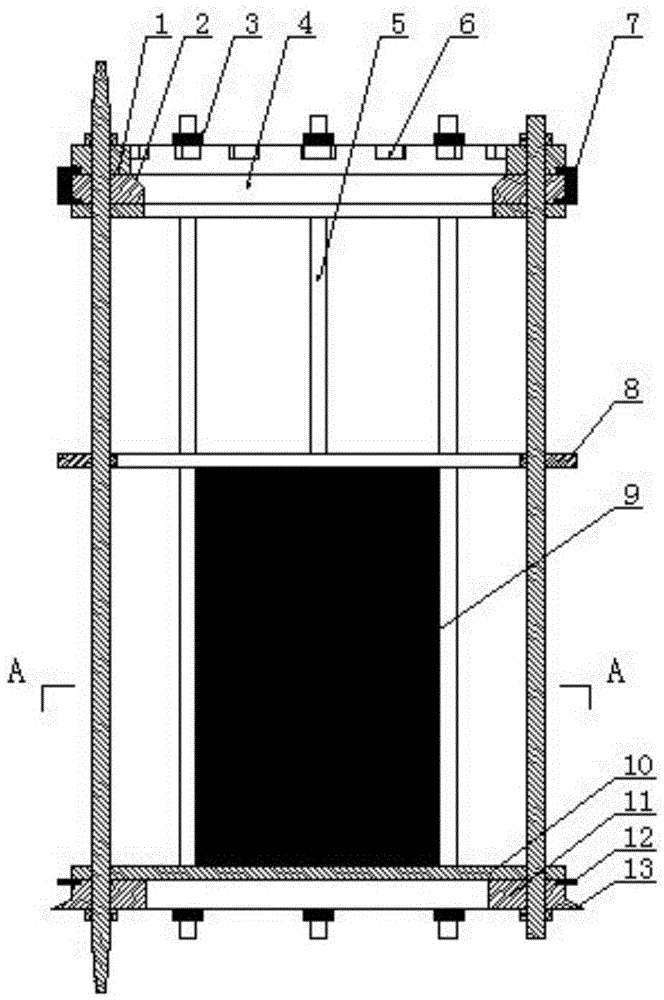

The invention relates to a steam-catapulting-type organic matter garbage disposal system. The system comprises a system frame, a pressure-maintaining catapulting device, a pressure-maintaining catapulting device screw cover controller, a liftable feeding funnel, a feeding lifting device, a discharging guide barrel and a steam-solid separator. The pressure-maintaining catapulting device, the pressure-maintaining catapulting device screw cover controller and the liftable feeding funnel are sequentially installed in the system frame from bottom to top, the feeding lifting device is installed on one side of the system frame, the discharging guide barrel is installed on the lower portion of the pressure-maintaining catapulting device, and the discharging guide barrel is connected with the steam-solid separator. The system is scientific and reliable in design, adaptable to instant catapulting, resistant to high pressure and high in strength, feeding is facilitated. When the steam catapulting is performed, discharging is uniformly and orderly, and the catapulting sliding is more stable.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

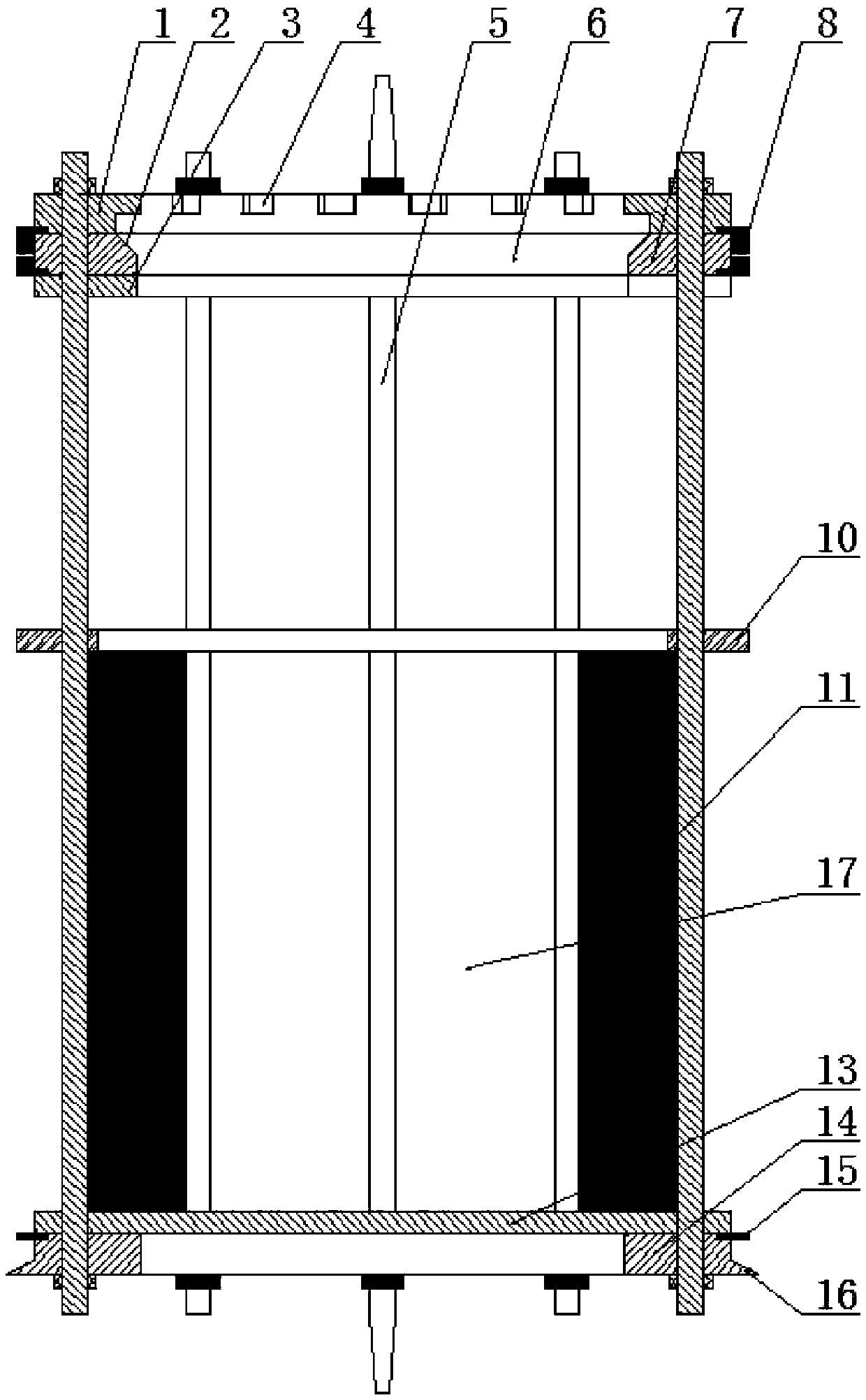

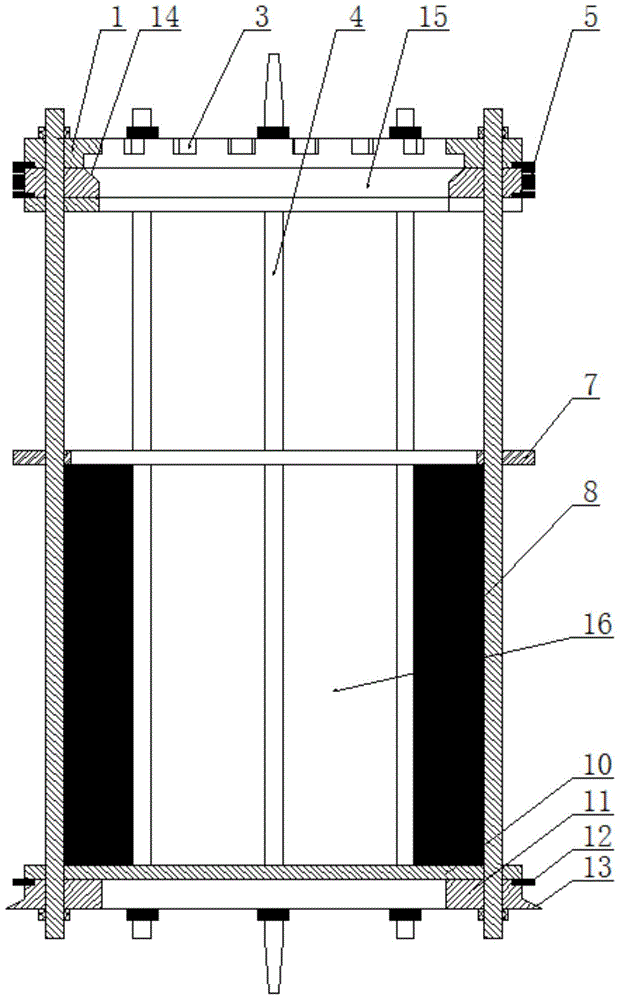

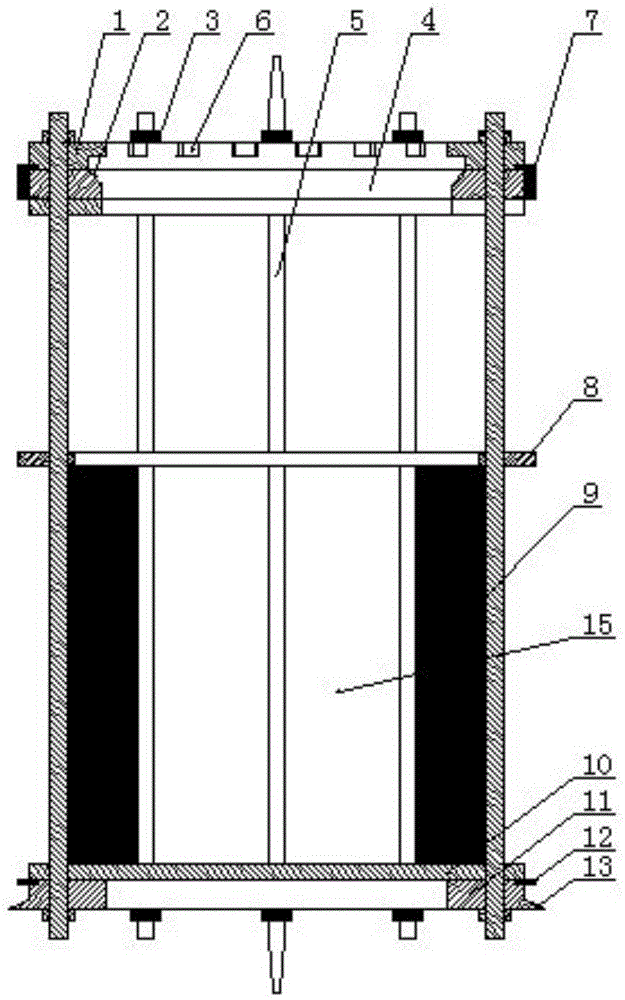

Steam ejection type organic waste disposer with discharge guide holes

ActiveCN103406334AEasy feedingSmooth feedingTransportation and packagingSolid waste disposalSteam pressureEngineering

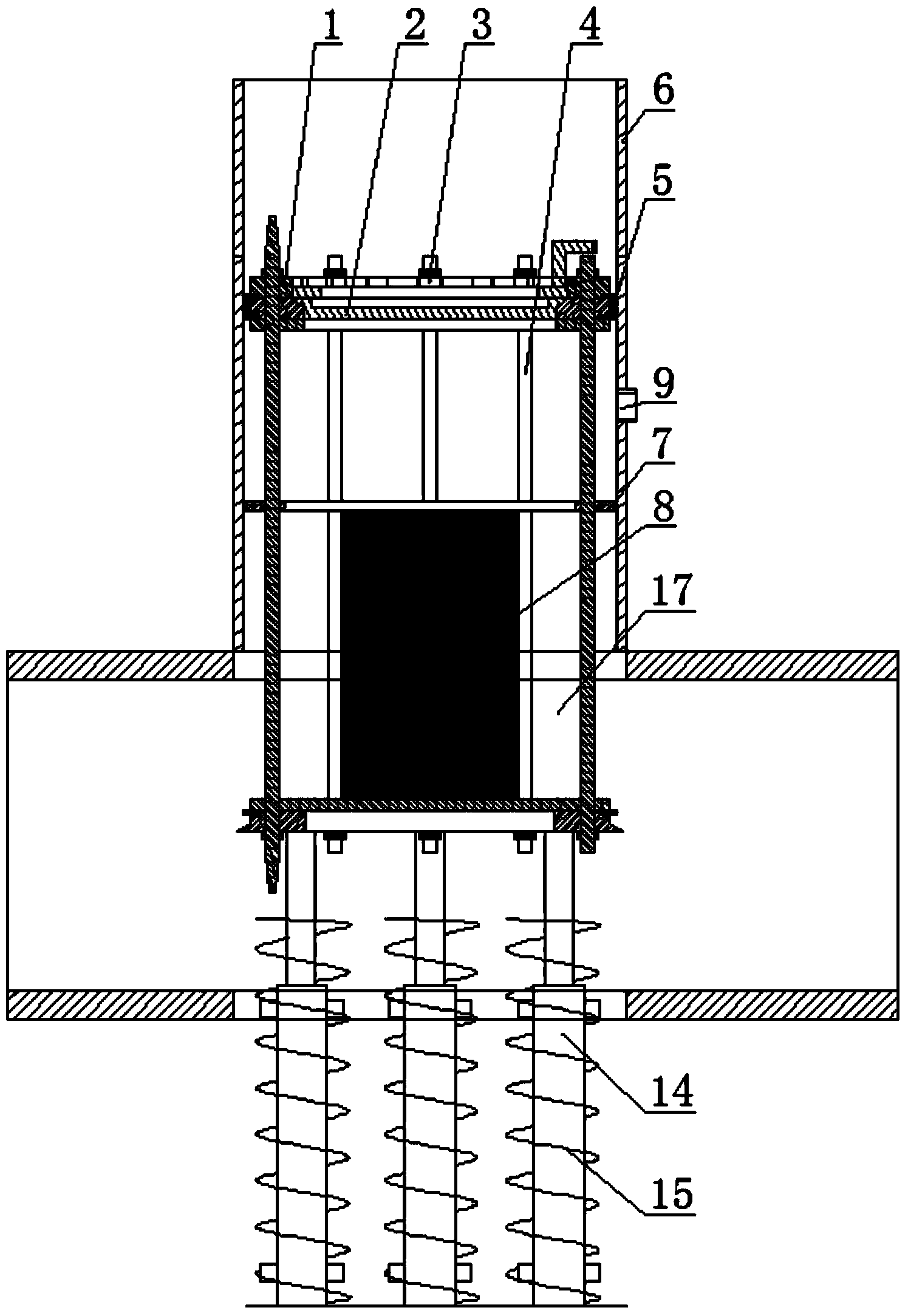

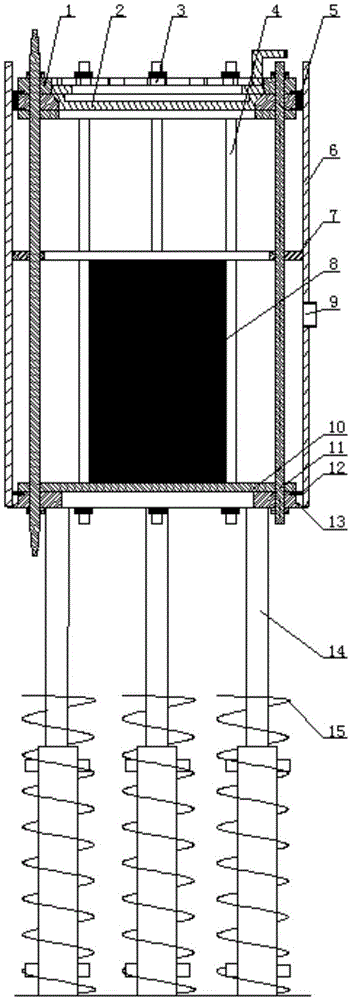

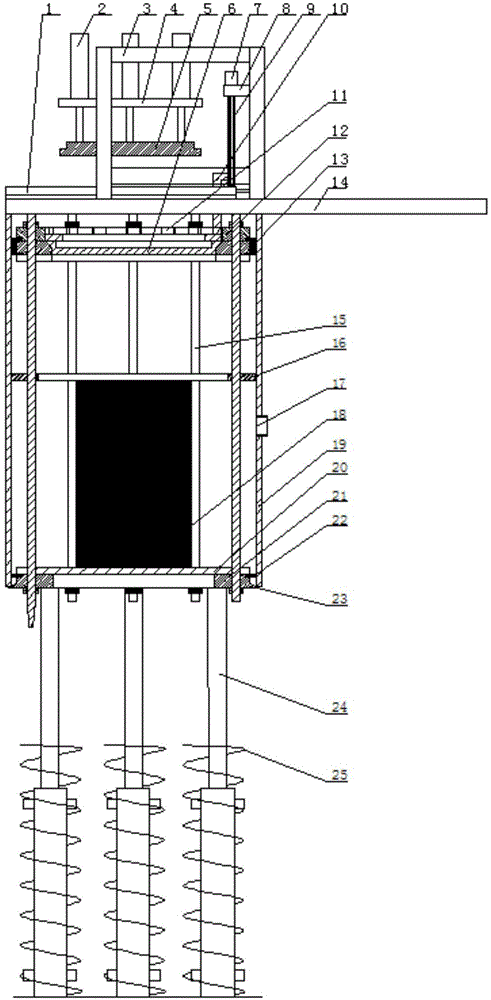

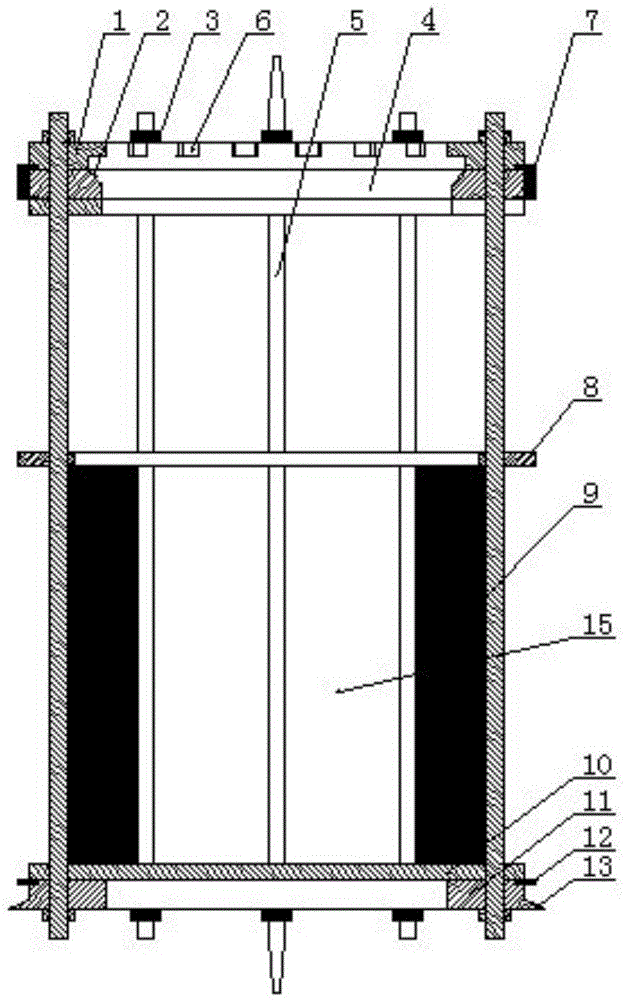

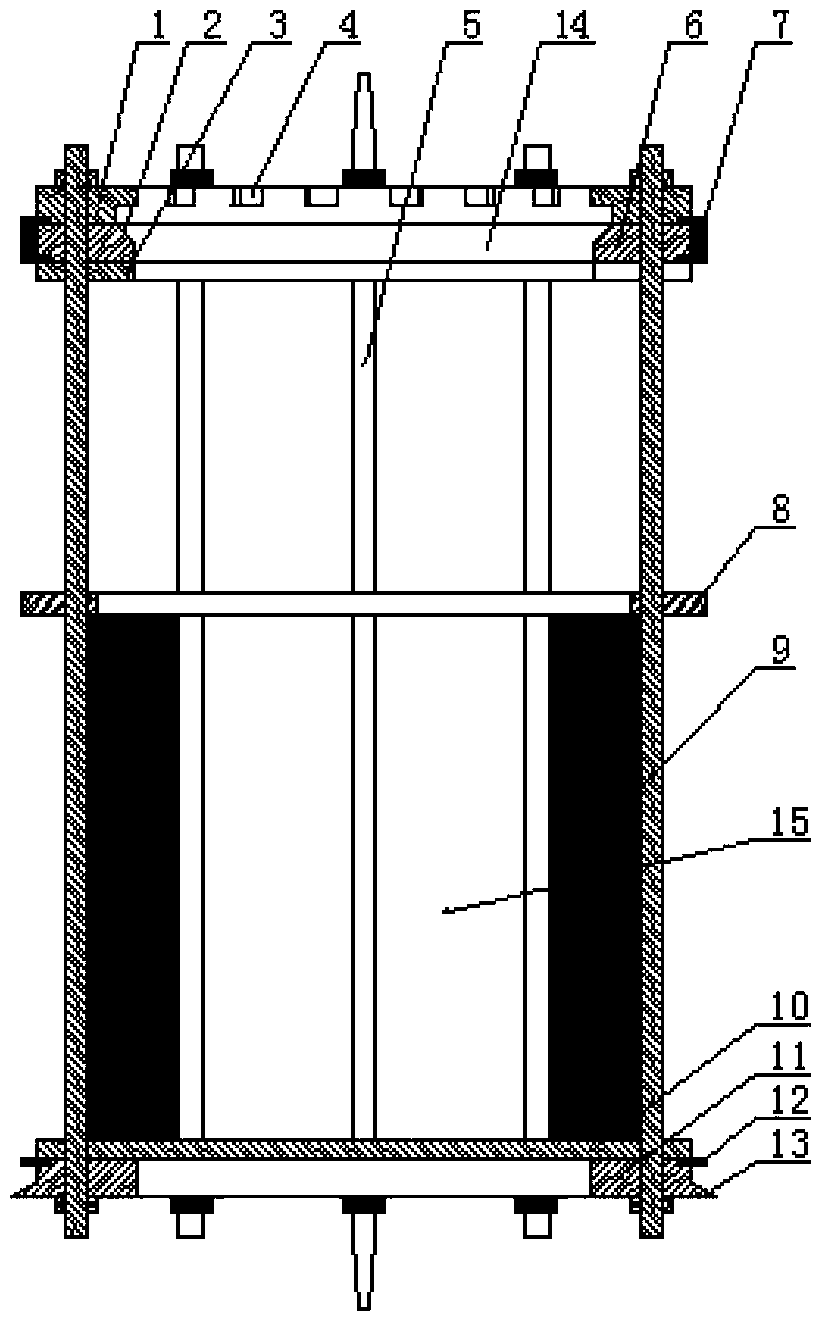

The invention relates to a steam ejection type organic waste disposer with discharge guide holes. The organic waste disposer comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap and ejection triggering cylinders, wherein the ejection steel cage is installed in the steam pressure maintaining steel cylinder in a sliding manner; a steam inlet is formed in the steam pressure maintaining steel cylinder; a feeding hole is formed at the upper end of the ejection steel cage; the lower end of the ejection steel cage and piston rods of the ejection triggering cylinders are fixedly installed; the feeding screw cap is installed at the feeding hole of the ejection steel cage; a discharge guide cylinder is installed at the lower end of the steam pressure maintaining steel cylinder; the ejection triggering cylinders pass through the discharge guide cylinder; and guide discharge holes are formed at the two ends of the discharge guide cylinder. The organic waste disposer has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength, is convenient for loading, is uniform and orderly in discharging during steam ejection, and is more stable in ejection sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

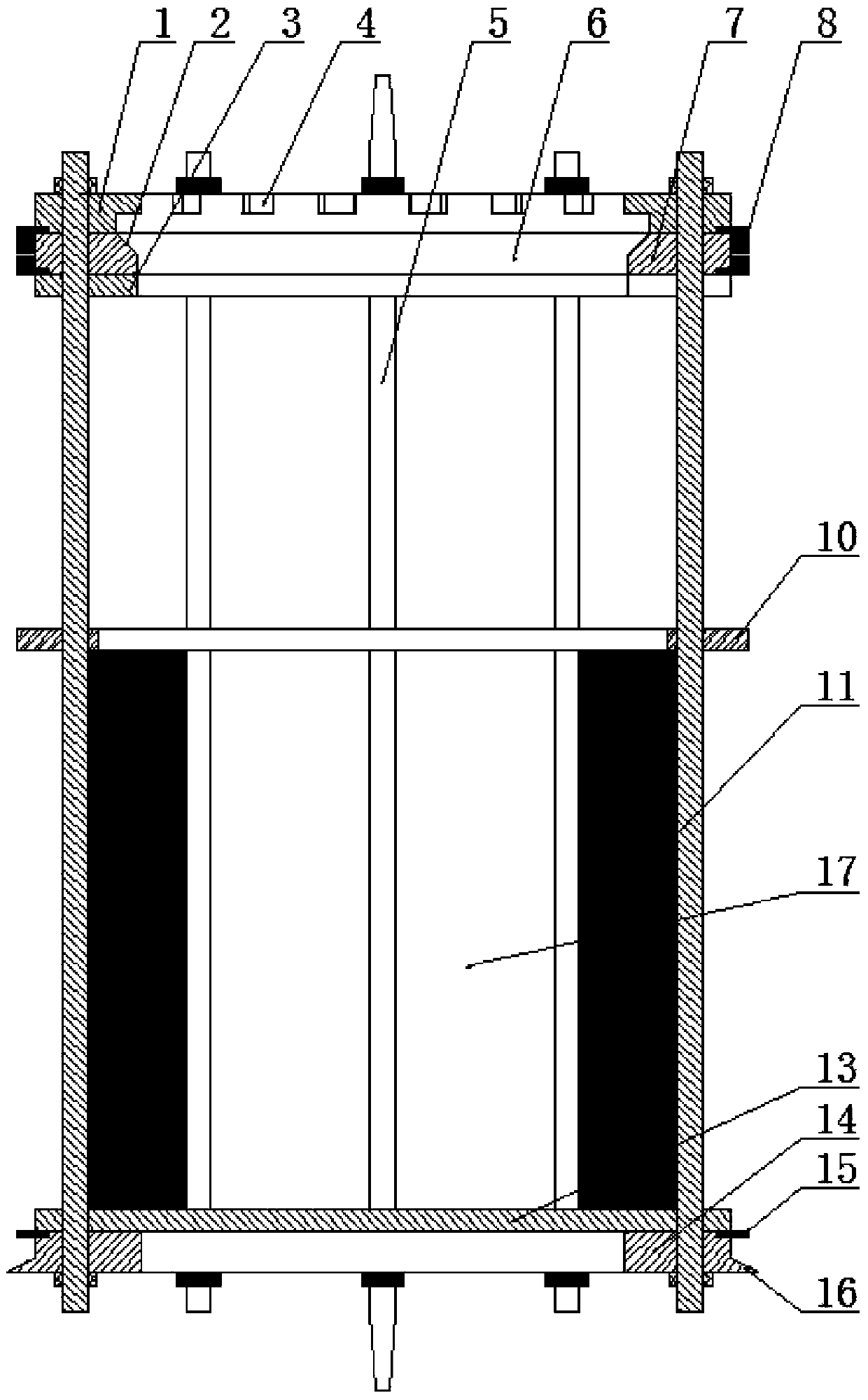

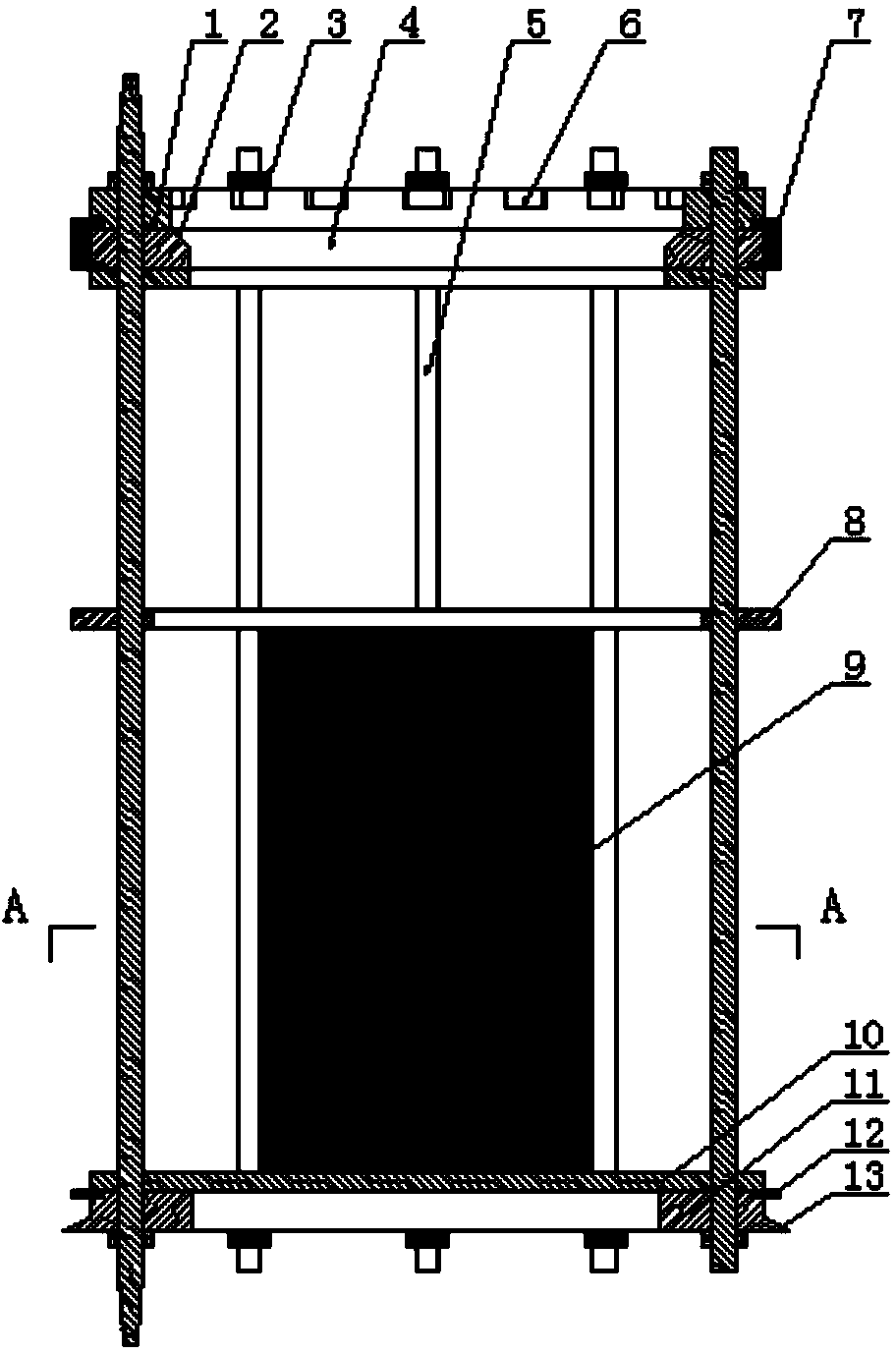

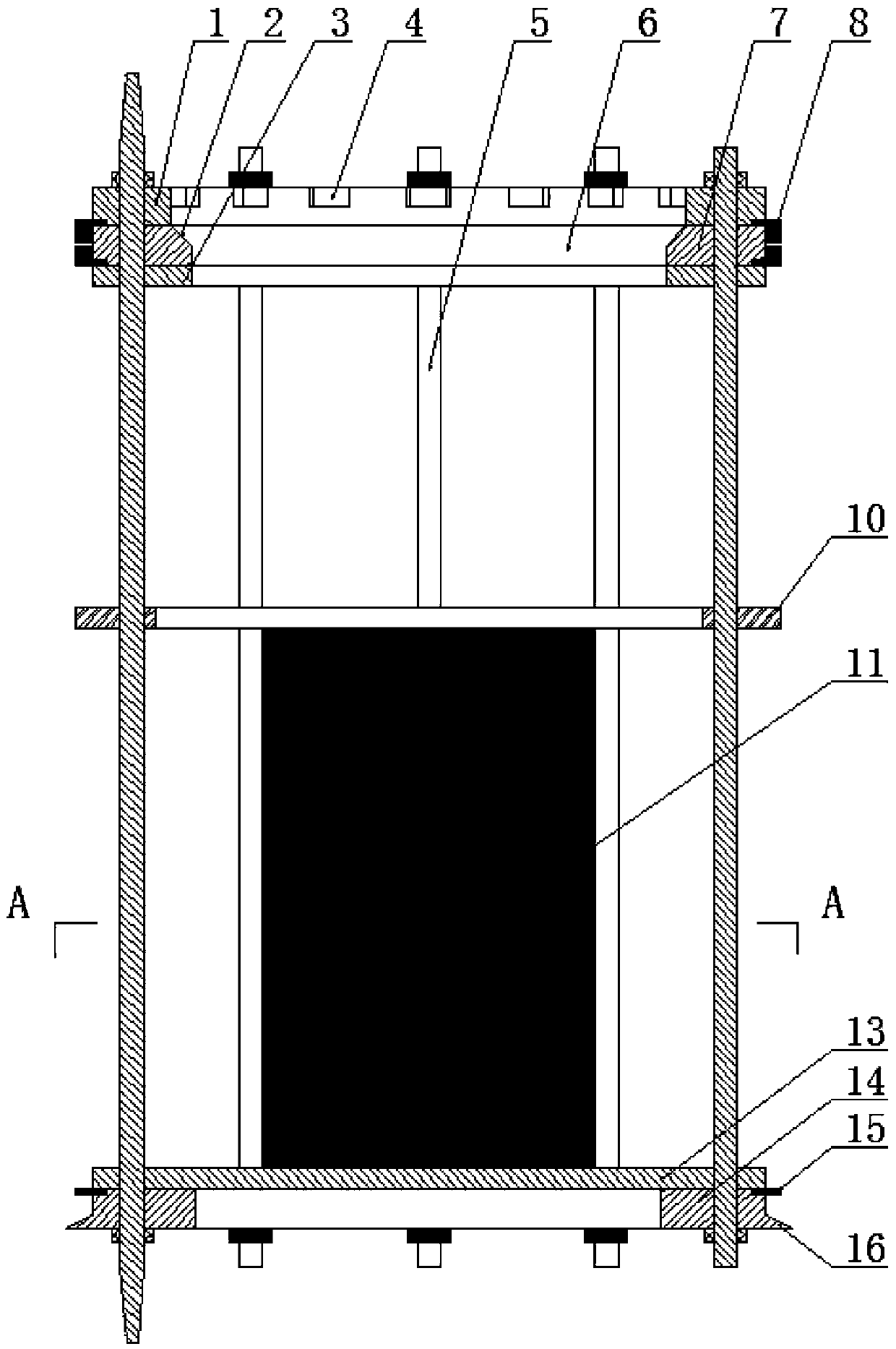

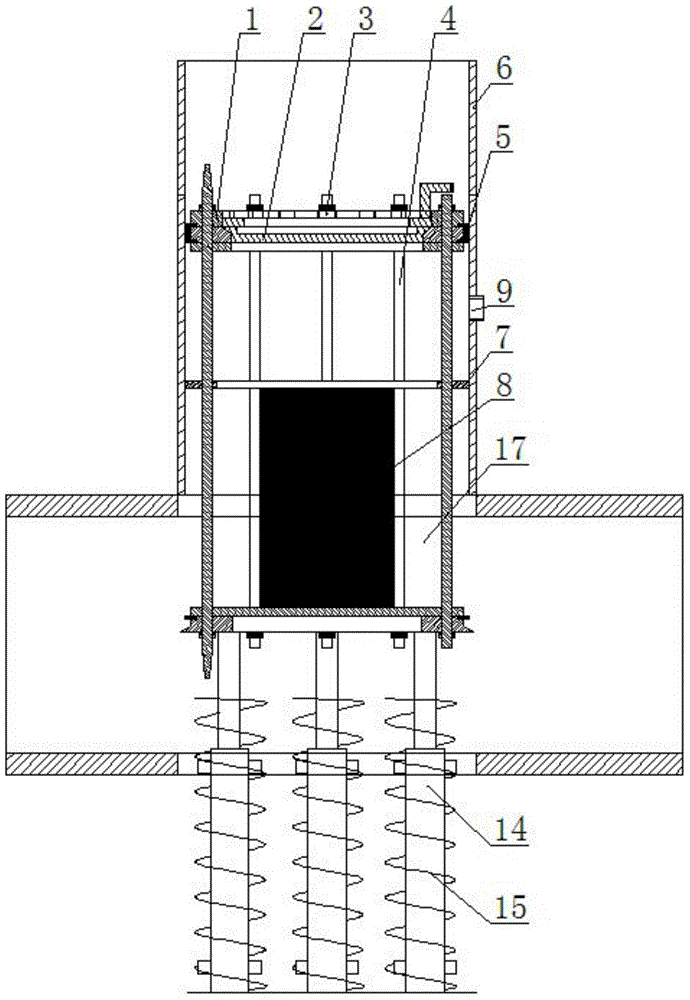

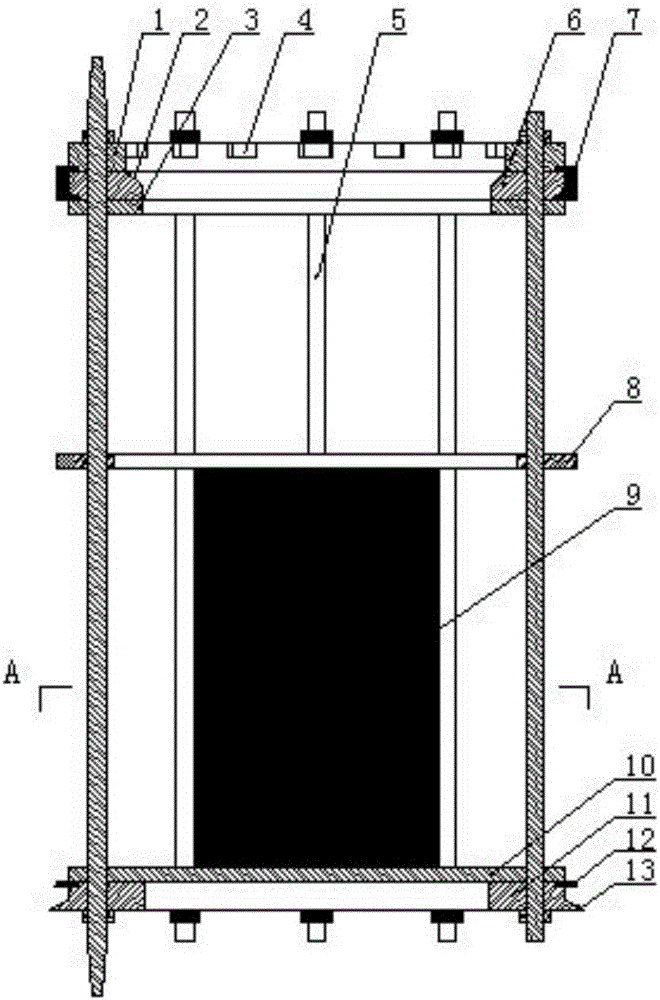

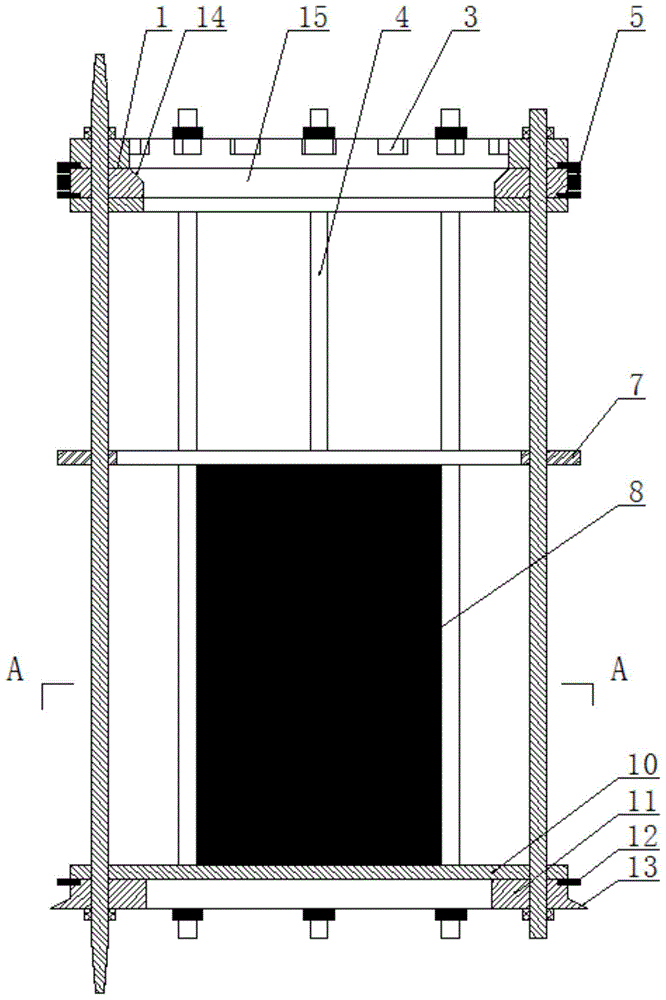

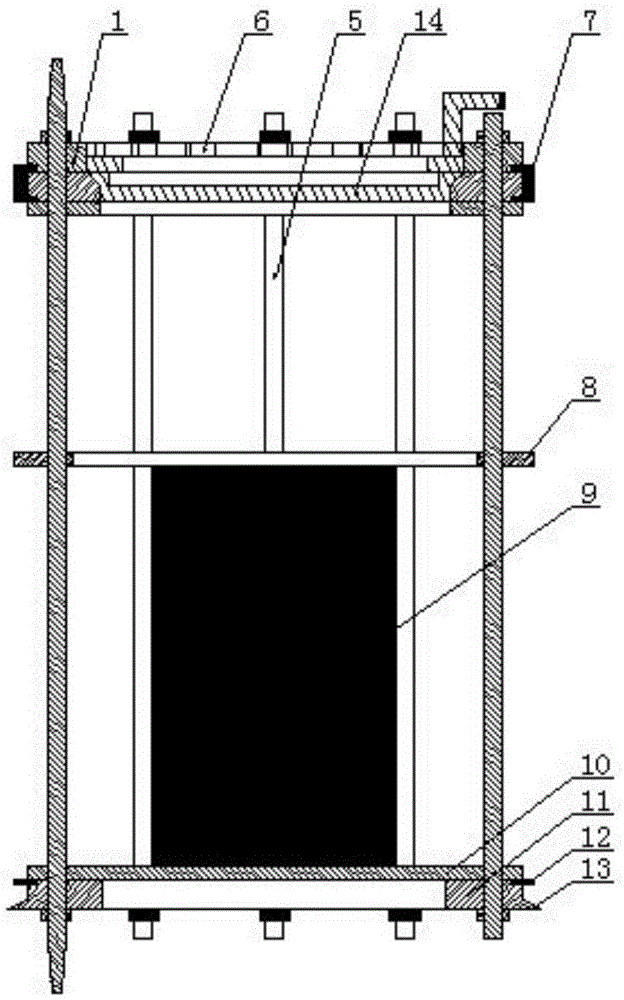

Pressure-maintaining ejection structure for steam ejection type organic matter garbage disposer

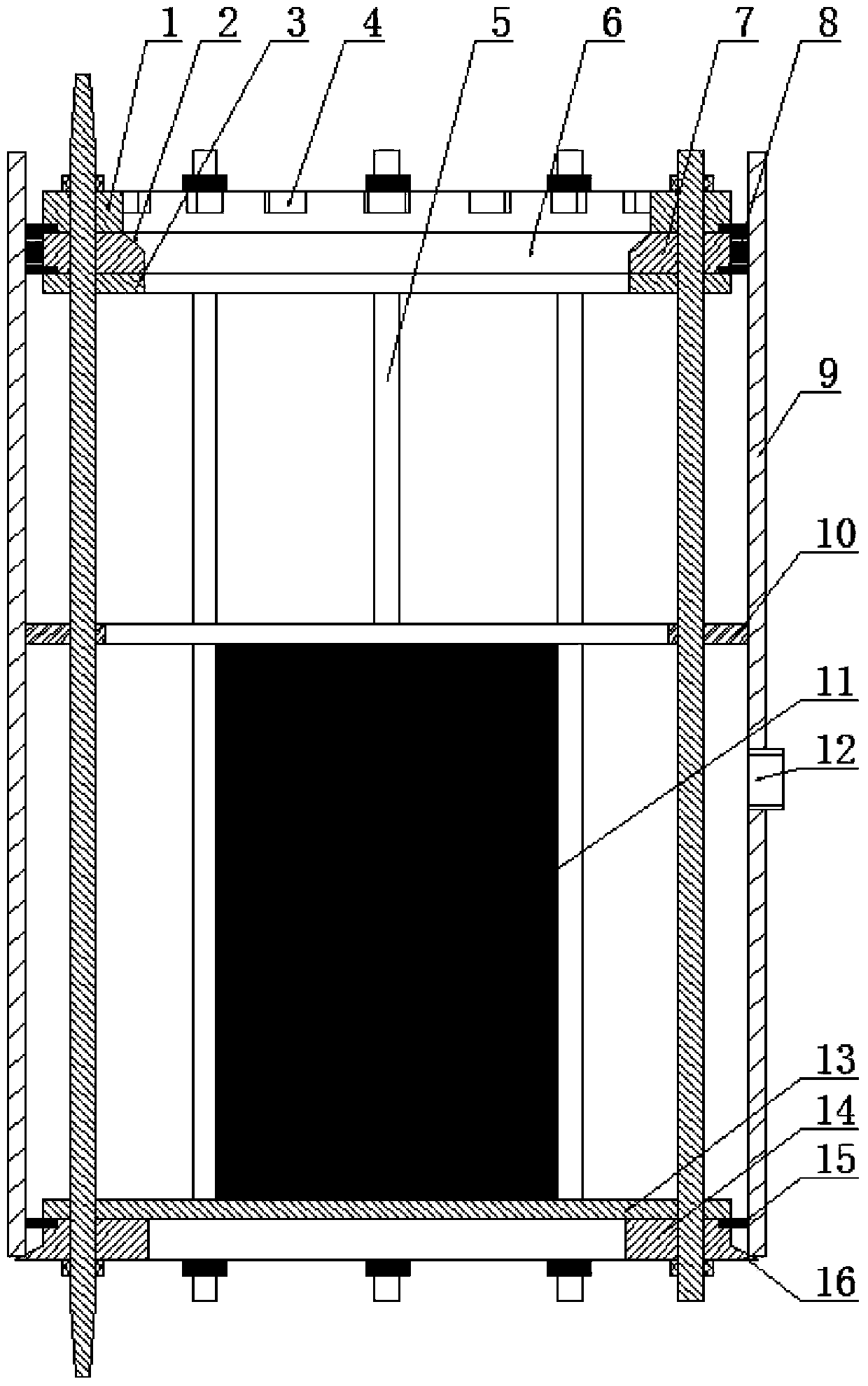

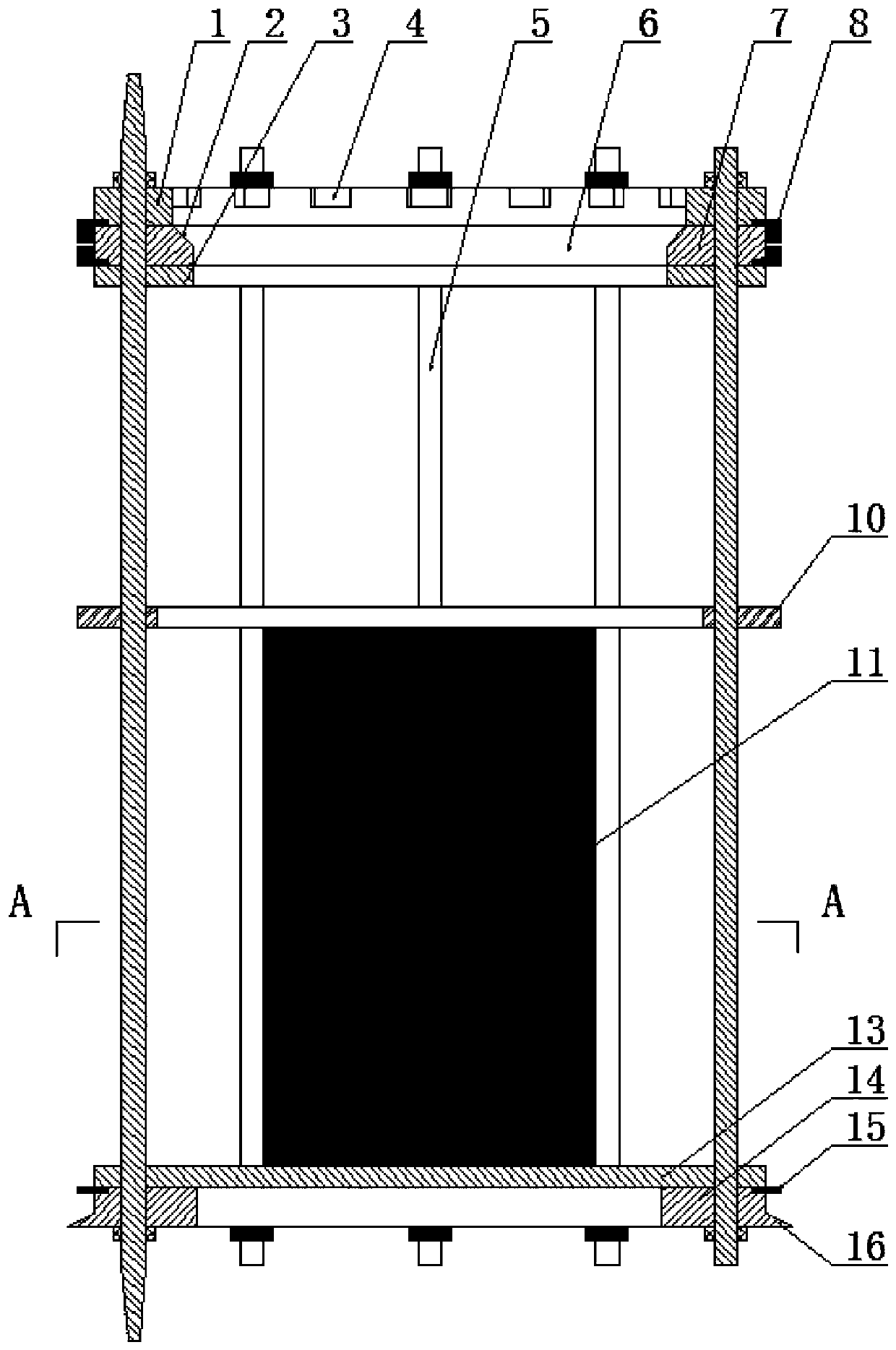

ActiveCN103433269AEasy feedingIncrease the feeding speedSolid waste disposalTransportation and packagingThermodynamicsSteam pressure

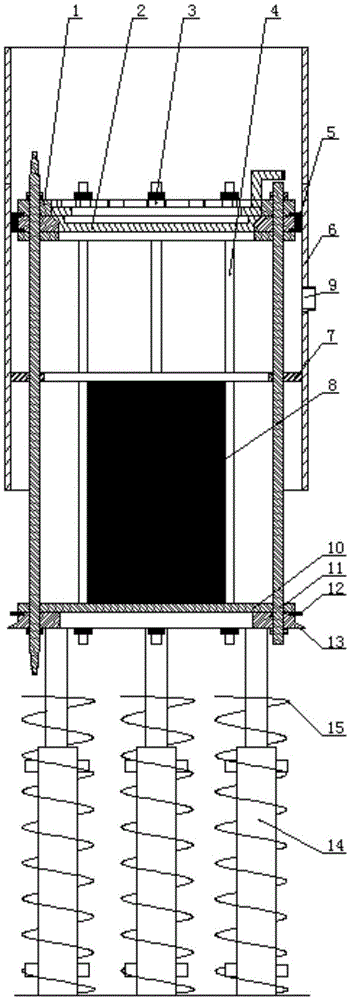

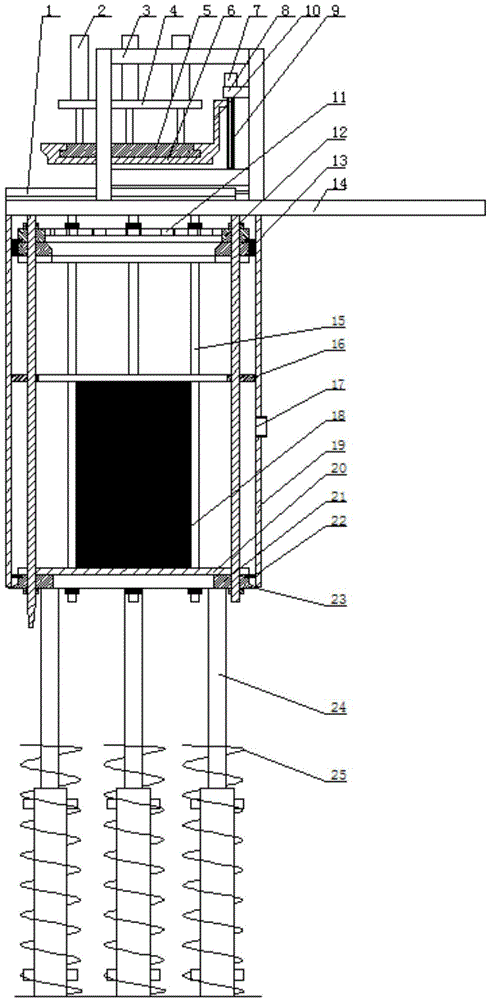

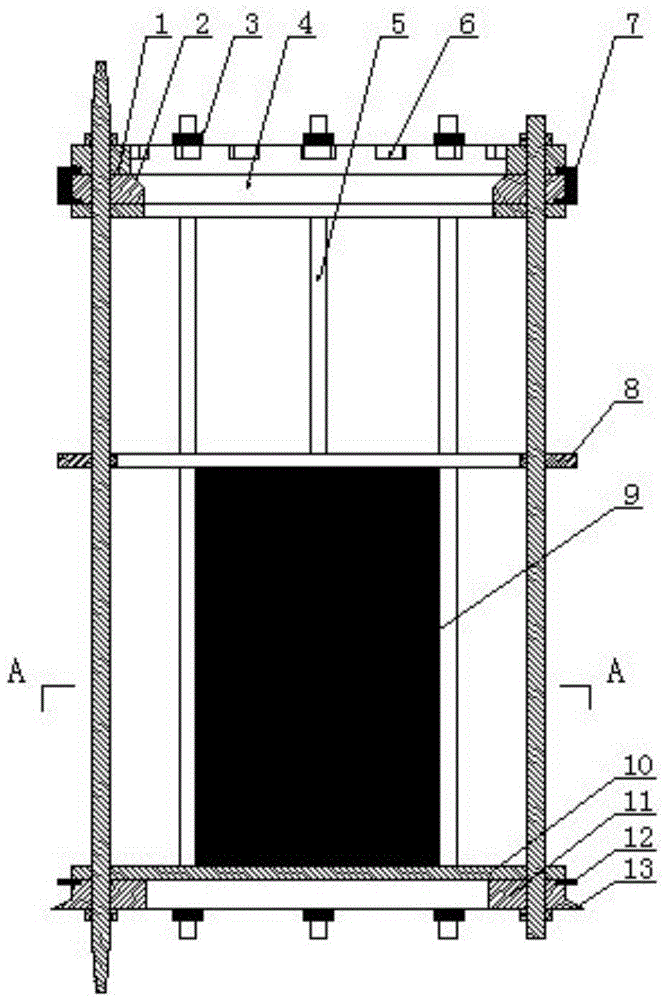

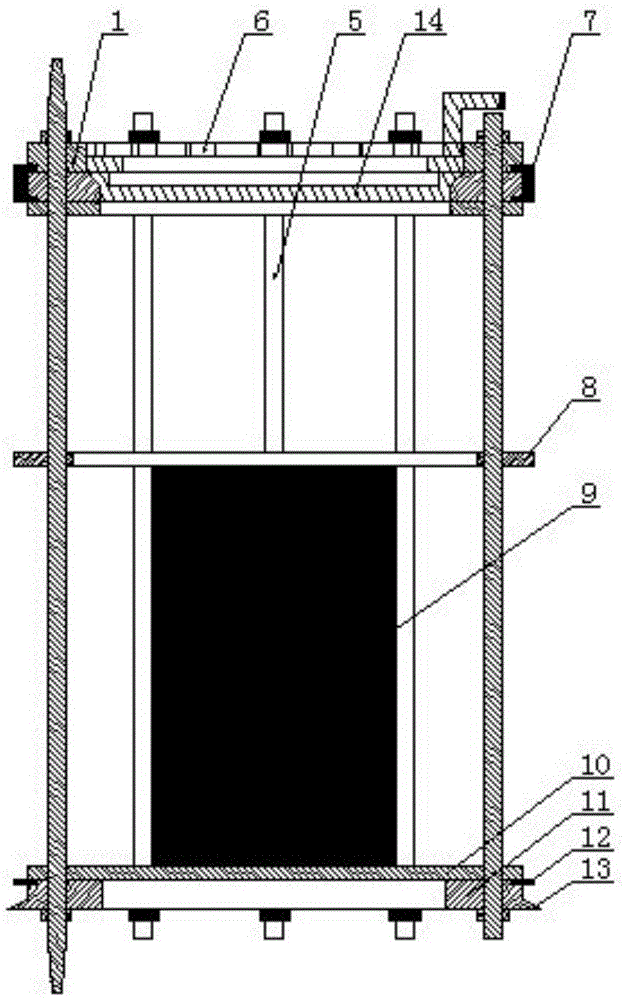

The invention relates to a pressure-maintaining ejection device for a steam ejection type organic matter garbage disposer. The pressure-maintaining ejection device comprises a steam pressure-maintaining steel cylinder, an ejection steel cage and a charging screwing cover, wherein the ejection steel cage is slidably arranged in the steam pressure-maintaining steel cylinder and comprises an upper sliding disk, a lower sliding disk and supporting columns; a charging hole is formed in the upper sliding disk; the charging screwing cover is arranged in a manner of being matched with the charging hole; material port limiting teeth are uniformly distributed at the upper edge of the inner wall of the charging hole; an inclined material port sealing wall is arranged on the inner wall of the charging hole below the material port limiting teeth; screwing cover locking teeth are arranged on the charging screwing cover corresponding to the material port limiting teeth; an inclined screwing cover sealing wall is arranged on the charging screwing cover corresponding to the inclined material port sealing wall; the supporting columns are fixedly arranged between the upper sliding disk at the periphery of the charging hole and the lower sliding disk. The pressure-maintaining ejection device is simple in structure, suitable for instant ejection, resistant to high pressure and high in strength; materials can be conveniently fed; when a steel cage structure is subjected to steam ejection, by virtue of the steel cage structure, the materials are discharged uniformly and orderly, and the steel cage steadily slides.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

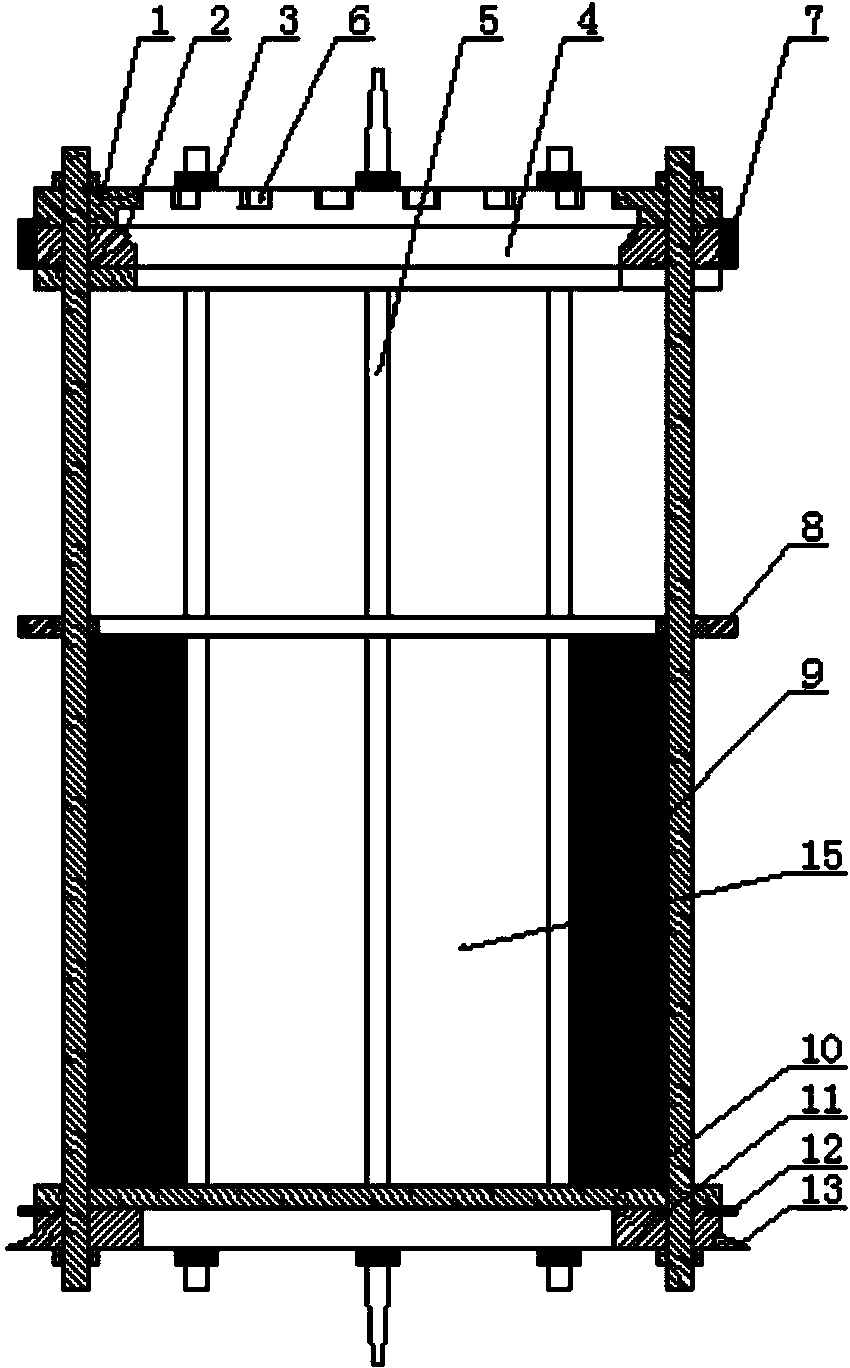

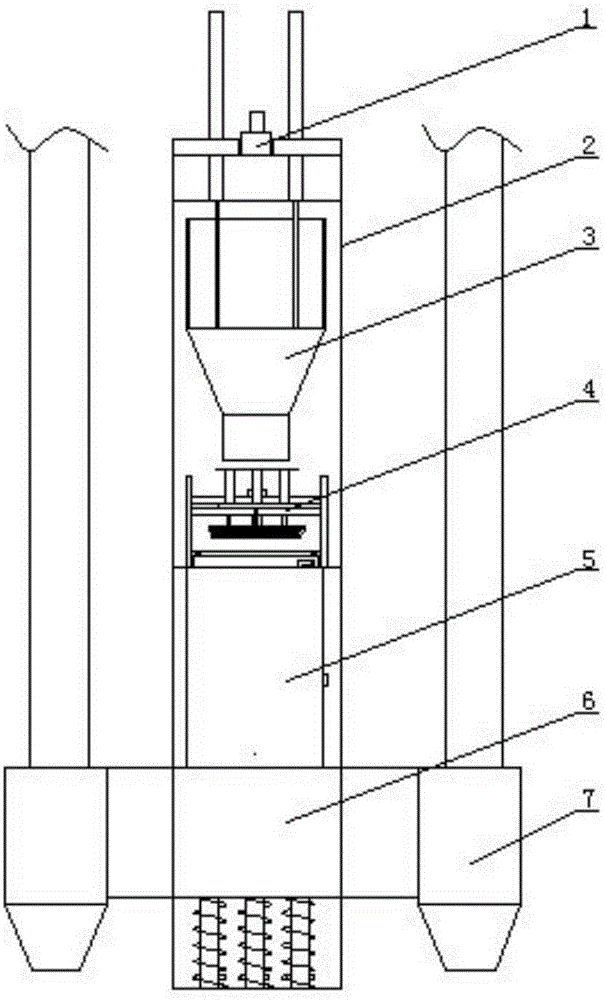

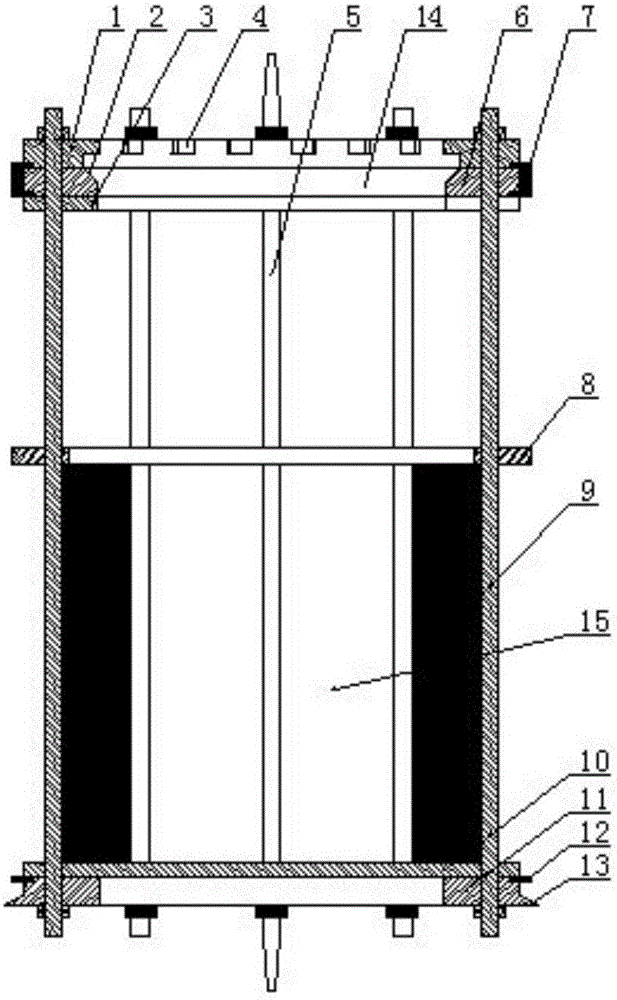

Steam ejection type organic garbage processor with steam-solid separation function

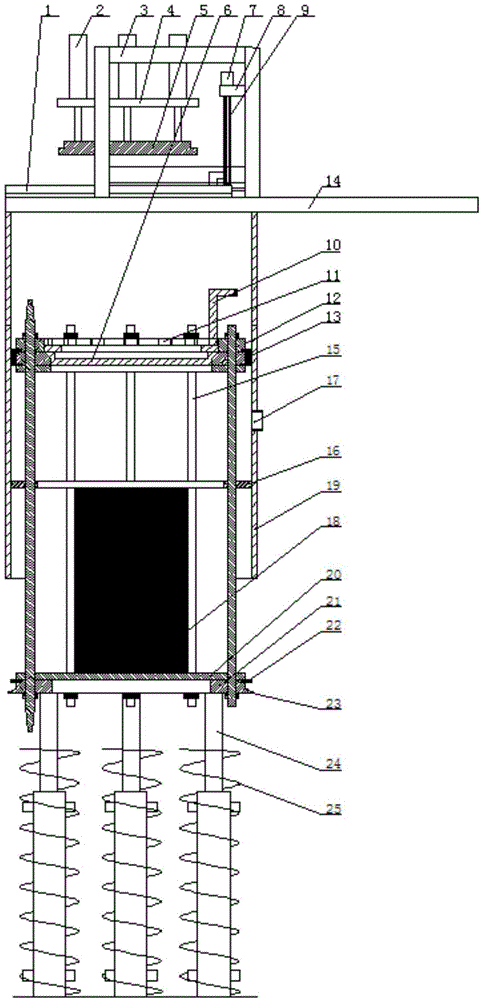

The invention relates to a steam ejection type organic garbage processor with a steam-solid separation function. The steam ejection type organic garbage processor comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap, an ejection trigger cylinder, a discharge guide cylinder and a steam-solid separator, wherein the ejection steel cage is arranged in the steam pressure maintaining steel cylinder in a sliding way; the upper end of the ejection steel cage has a feeding hole; the lower end of the ejection steel cage is fixed with a piston rod of the ejection trigger cylinder; the feeding screw cap is arranged on the feeding hole of the ejection steel cage; the lower end of the steam pressure maintaining steel cylinder is connected with the steam-solid separator by the discharge guide cylinder; the steam pressure maintaining steel cylinder is provided with a steam inlet. The steam ejection type organic garbage processor is simple in structure, can adapt to instantaneous ejection, is high pressure resistant, high in strength and convenient in feeding, is even and orderly in discharging during steam ejection, can effectively separate the steam from slurry material, and is more stable in ejection and slide.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

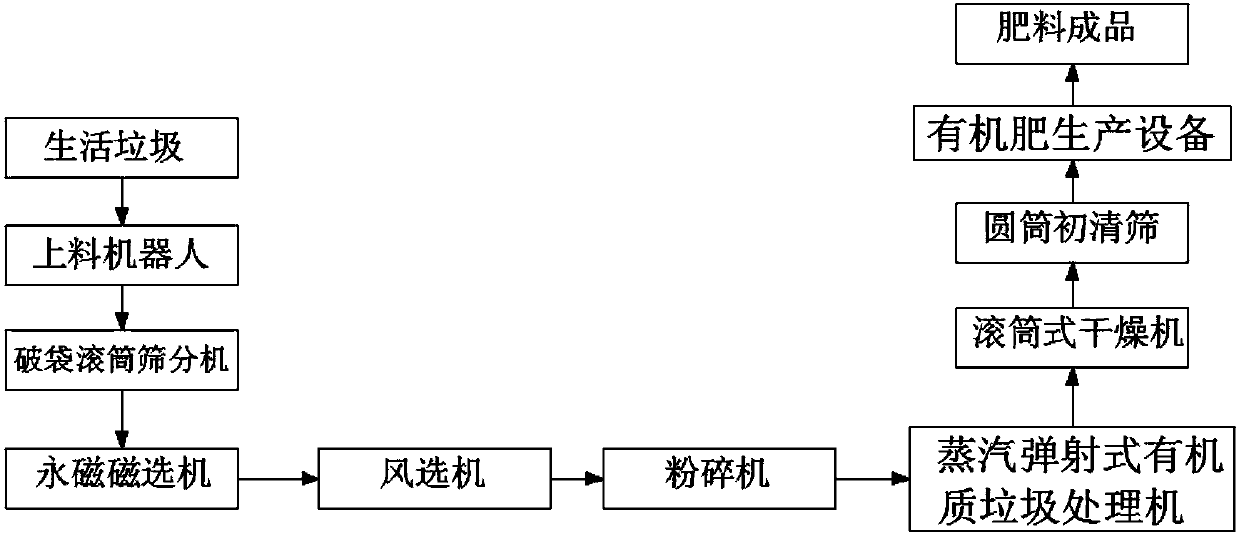

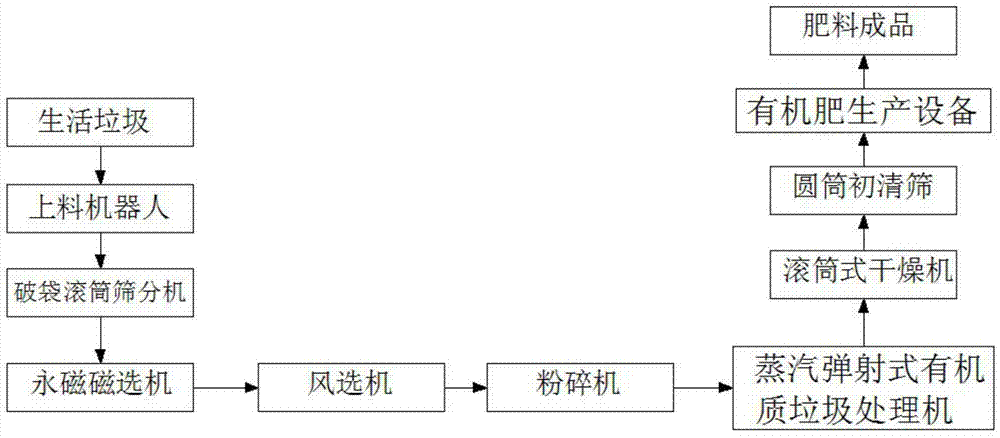

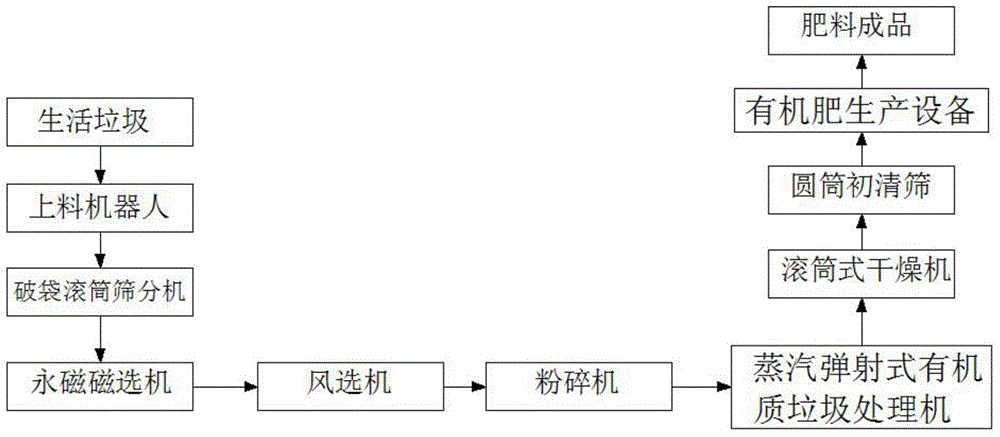

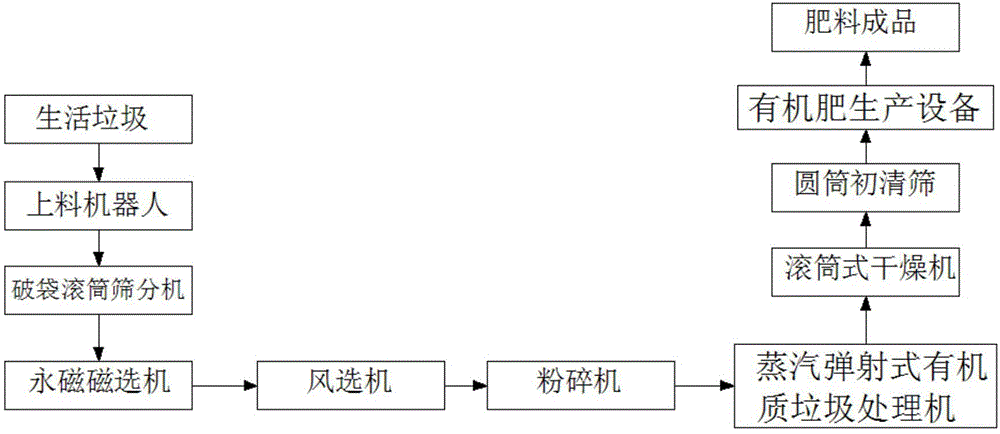

System for using household garbage for making fertilizer rapidly

InactiveCN103420690AShort throughputLarge amount of processingBio-organic fraction processingProductsMagnetic separatorPulp and paper industry

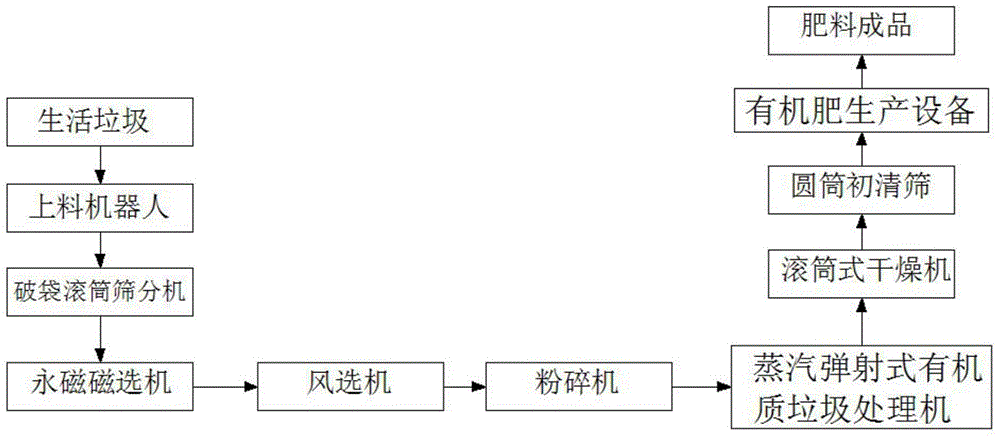

The invention relates to a system for using household garbage for making fertilizer rapidly. The system comprises a feeding robot, a bag-breaking roller screening machine, a permanent magnet magnetic separator, a winnowing machine, a steam pop-up organic matter garbage disposer, a roller drier, a cylinder precleaner, a conveyor and organic fertilizer production equipment. The feeding robot is connected with an inlet of the bag-breaking roller screening machine through the conveyor, an outlet of the bag-breaking roller screening machine is connected with an inlet of the permanent magnet magnetic separator, an outlet of the permanent magnet magnetic separator is connected with an inlet of the winnowing machine, the winnowing machine is connected with the steam pop-up organic matter garbage disposer which is connected with an inlet of the roller drier, an outlet of the roller drier is connected with an inlet of the cylinder precleaner through the conveyor, and the cylinder precleaner is connected with the organic fertilizer production equipment through the conveyor. The system for using the household garbage for making the fertilizer rapidly is short in fertilizer making time, large in treating amount of the garbage, high in fertilizer efficiency, convenient to produce, high in operability and environmentally friendly, effectively solves the problems that the garbage pollutes the environment and harm the ecology and achieves cycle use.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Organic refuse treatment system with feeding rotary cover provided with rotary shifting handle

InactiveCN105964374AEasy feedingIncrease the feeding speedTransportation and packagingGrain treatmentsSystems designHigh pressure

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

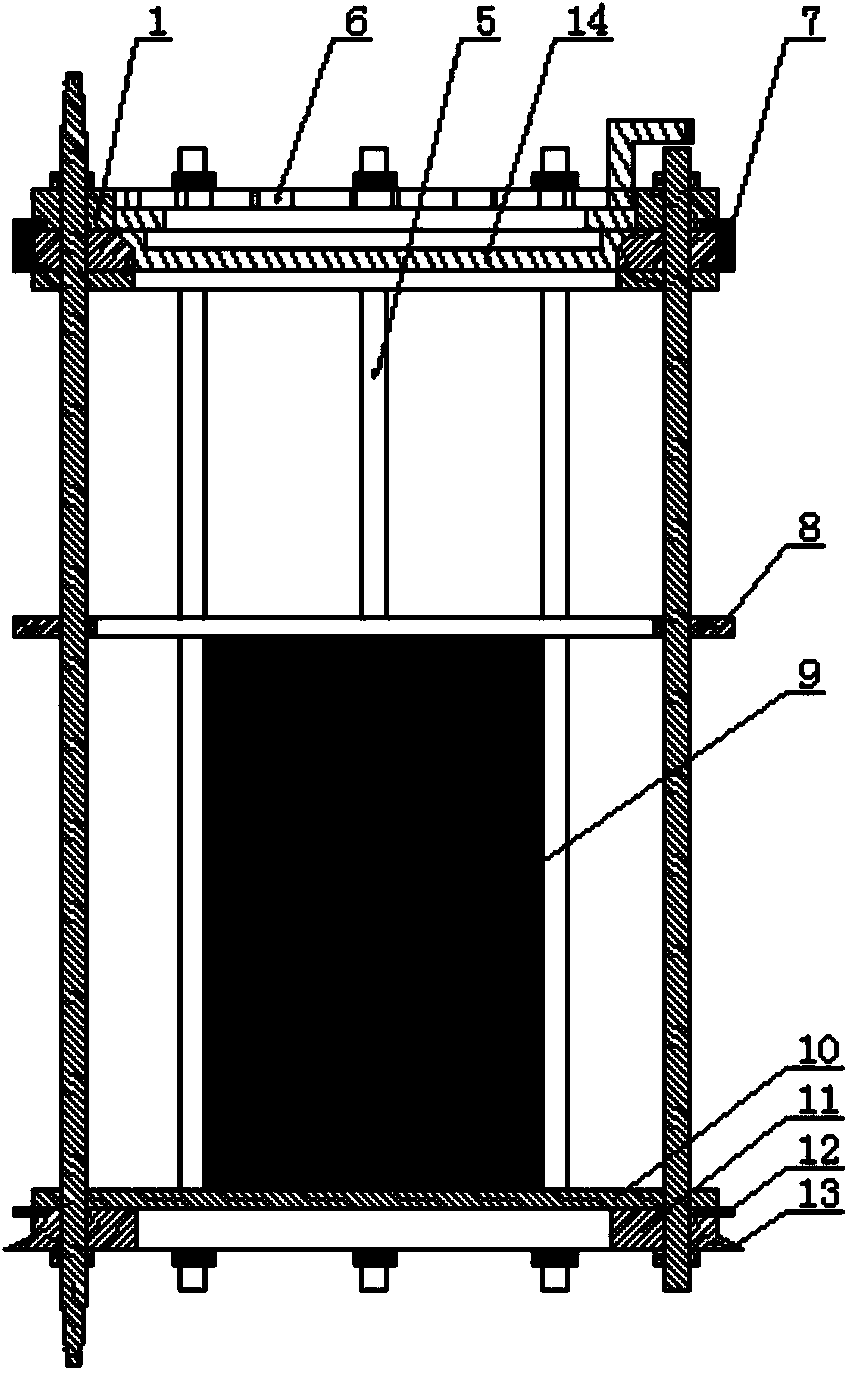

Steam ejection type organic waste disposer with feeding screw cap screwing function

ActiveCN103406336AEasy feedingFast feeding speedSolid waste disposalTransportation and packagingEngineeringScrew cap

The invention relates to a steam ejection type organic waste disposer with a feeding screw cap screwing function. The organic waste disposer comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap, a cap screwing control device and ejection triggering cylinders, wherein the ejection steel cage is installed in the steam pressure maintaining steel cylinder in a sliding manner; a steam inlet is formed in the steam pressure maintaining steel cylinder; a feeding hole is formed at the upper end of the ejection steel cage; the lower end of the ejection steel cage and piston rods of the ejection triggering cylinders are fixedly installed; the feeding screw cap is installed at the feeding hole of the ejection steel cage; and the cap screwing control device is installed on the steam pressure maintaining steel cylinder above the feeding screw cap. The organic waste disposer has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength, is convenient for loading, is uniform and orderly in discharging during steam ejection, and is more stable in ejection sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam catapult organic waste disposer

ActiveCN103406339BEasy feedingSmooth feedingSolid waste disposalTransportation and packagingSteam pressureEngineering

The invention relates to a steam ejection type organic waste disposer, which comprises a steam pressure-holding steel cylinder, an ejection steel cage, a feed screw cap and an ejection triggering cylinder. The ejection steel cage is slidingly installed in the steam pressure-holding steel cylinder, and the steam pressure A steam inlet is formed on the steel cylinder, a feed inlet is formed on the upper end of the ejection steel cage, the lower end of the ejection steel cage is fixedly mounted with the piston rod of the ejection trigger cylinder, and the feed screw cap is installed on the feed inlet of the ejection steel cage. The invention has the advantages of simple structure, adaptability to instantaneous ejection, high pressure resistance, high strength, convenient material feeding, even and orderly discharge during steam ejection, and more stable ejection sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam catapulting type organic matter garbage disposal machine with discharge guide plate

PendingCN104646401AEasy feedingSmooth feedingSolid waste disposalSteam pressurePulp and paper industry

The invention relates to a steam catapulting type organic matter garbage disposal machine with a discharge guide plate. The steam catapulting type organic matter garbage disposal machine comprises a steam pressure-keeping steel cylinder, a catapulting steel cage, a feed rotary cover and a catapulting initiation cylinder, wherein the catapulting steel cage is mounted in the steam pressure-keeping steel cylinder in a sliding manner, a steam inlet is formed in the steam pressure-keeping steel cylinder, a feed inlet is formed in the upper end of the catapulting steel cage, the lower end of the catapulting steel cage and a piston rod of the catapulting initiation cylinder are fixedly arranged, the feed rotary cover is mounted on the feed inlet of the catapulting steel cage, a discharge guide cylinder is mounted at the lower end of the steam pressure-keeping steel cylinder, the catapulting initiation cylinder penetrates through the discharge guide cylinder, guide discharge outlets are formed in two ends of the discharge guide cylinder, and the catapulting steel cage comprises an upper sliding disc, a lower sliding disc and a support column. The steam catapulting type organic matter garbage disposal machine provided by the invention has the advantages of simple structure, effect of being suitable for instantaneous catapulting, high pressure resistance, high strength, convenience in charging, uniform and ordered discharge during stream catapulting, and more smooth catapulting sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Fertilizer preparation system for organic garbage disposal unit with sliding guide ring

PendingCN104649730ALarge amount of processingFertilizer time is shortClimate change adaptationOrganic fertilisersMagnetic separatorPulp and paper industry

The invention relates a fertilizer preparation system for an organic garbage disposal unit with a sliding guide ring. A charging robot is connected with the inlet of a bag breaking roller screening machine through a conveyer, the outlet of the bag breaking roller screening machine is connected with the inlet of a permanent magnetic separator, the outlet of the permanent magnetic separator is connected with the inlet of a winnowing machine, the winnowing machine is connected with a gas-steam ejecting organic garbage disposal unit, the gas-steam ejecting organic garbage disposal unit is connected with the inlet of a roller drier, the outlet of the roller drier is connected with the inlet of a cylinder precleaner through the conveyer, the cylinder precleaner is connected with organic fertilizer production equipment through the conveyer, and the gas-steam ejecting organic garbage disposal unit comprises a system frame, a pressurizing ejecting device, a spiral cover controller of the pressurizing ejecting device, a liftable feeding funnel, a charging lifting device, a discharging guide cylinder and a gas-solid separator. The system provided by the invention is short in fertilizer preparation time, great in garbage disposal amount, high in efficiency, convenient to produce and strong in operability, solves the problem that garbage pollutes the environment and causes ecological hazards, and realizes cyclic utilization, so that the system is green and environmentally friendly.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Vapor-solid separation type organic garbage disposal machine

The invention relates to a steam ejection type organic garbage processor with a steam-solid separation function. The steam ejection type organic garbage processor comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap, an ejection trigger cylinder, a discharge guide cylinder and a steam-solid separator, wherein the ejection steel cage is arranged in the steam pressure maintaining steel cylinder in a sliding way; the upper end of the ejection steel cage has a feeding hole; the lower end of the ejection steel cage is fixed with a piston rod of the ejection trigger cylinder; the feeding screw cap is arranged on the feeding hole of the ejection steel cage; the lower end of the steam pressure maintaining steel cylinder is connected with the steam-solid separator by the discharge guide cylinder; the steam pressure maintaining steel cylinder is provided with a steam inlet. The steam ejection type organic garbage processor is simple in structure, can adapt to instantaneous ejection, is high pressure resistant, high in strength and convenient in feeding, is even and orderly in discharging during steam ejection, can effectively separate the steam from slurry material, and is more stable in ejection and slide.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam ejection type organic waste disposer with feeding cap screwing function

InactiveCN103406336BEasy feedingSmooth feedingSolid waste disposalTransportation and packagingSteam pressureEngineering

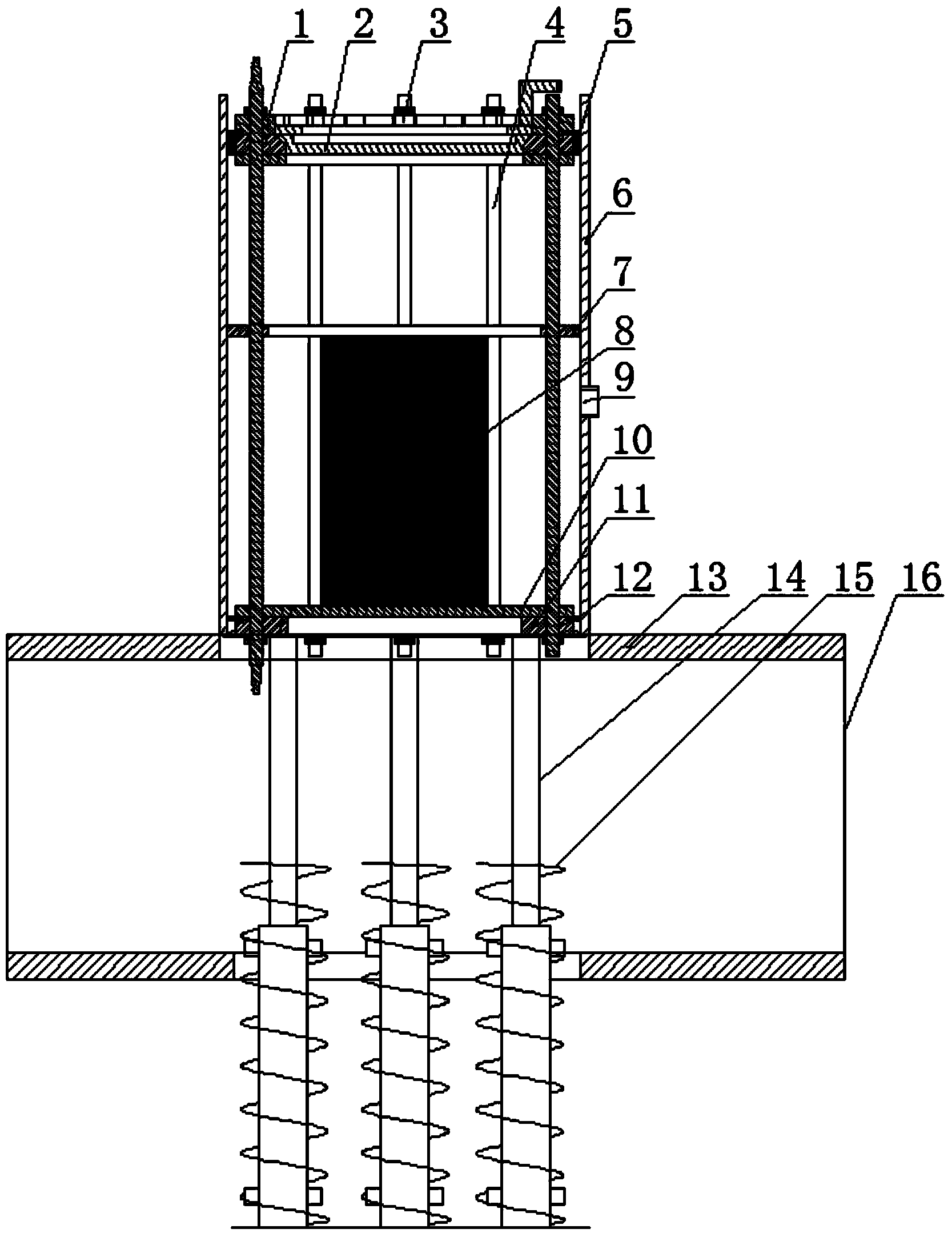

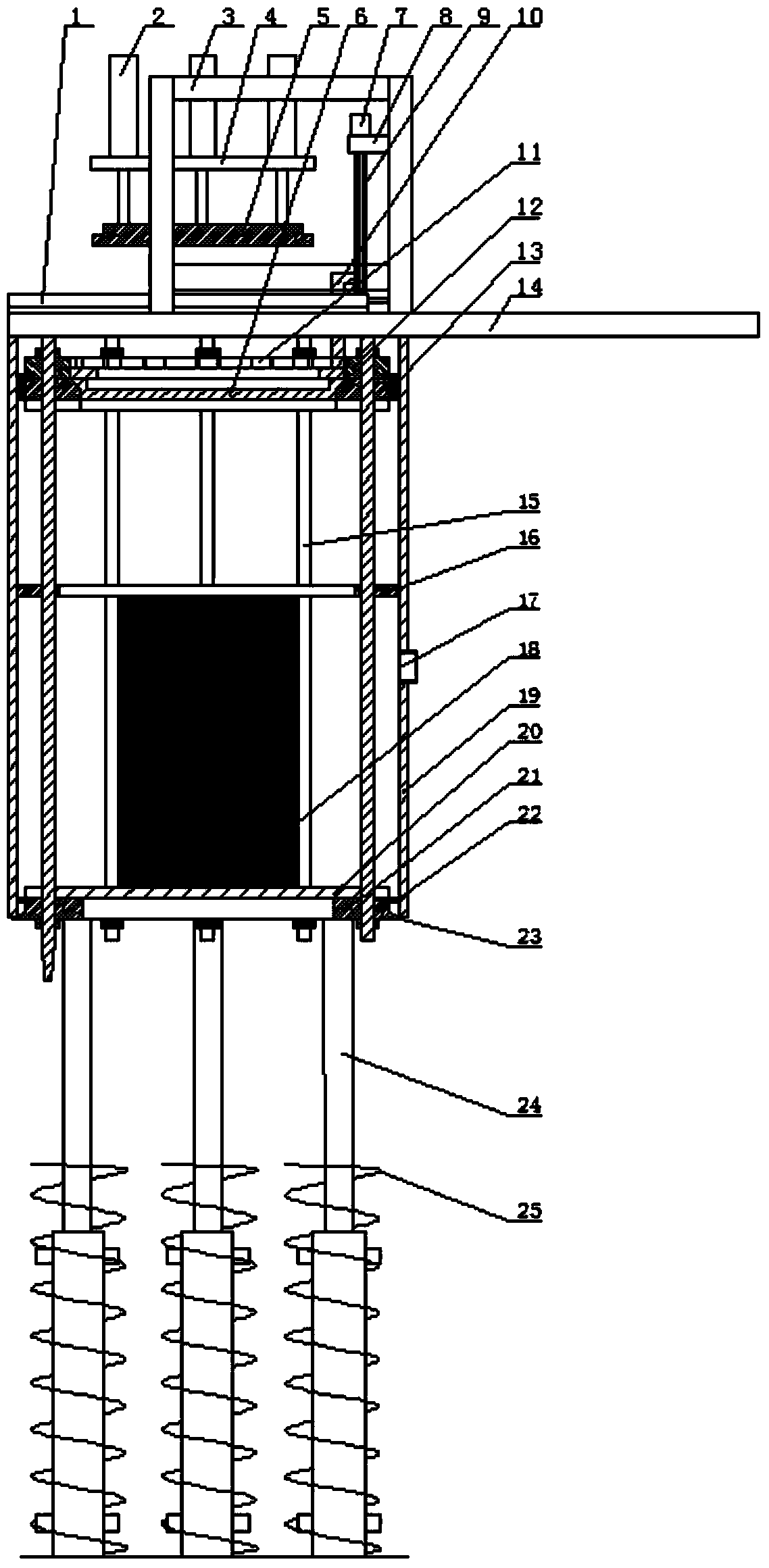

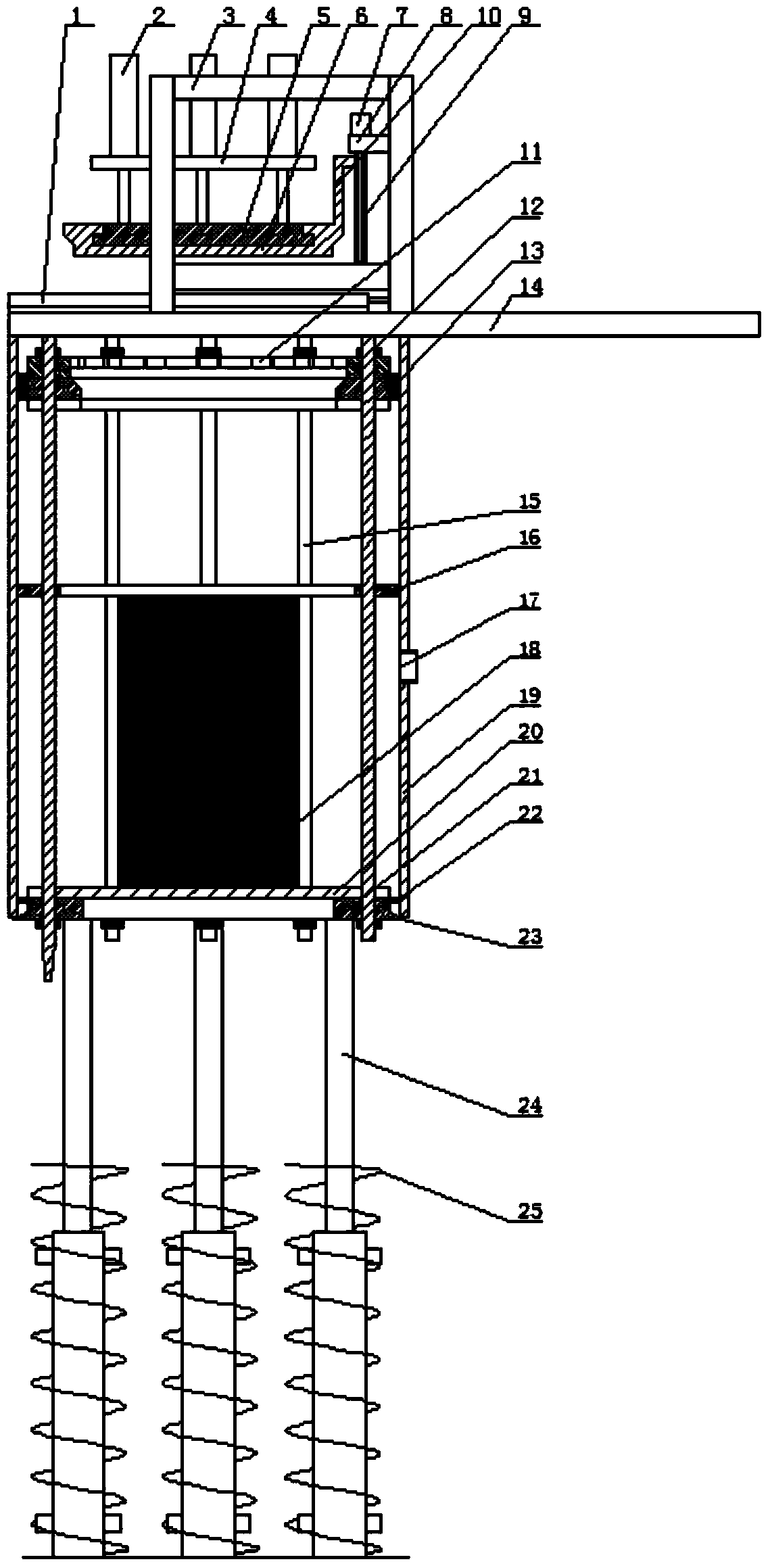

Disclosed is a steam ejection type organic garbage disposer with a screwing function of a feed screw cap, which comprises a steam pressure maintaining steel cylinder (19), an ejection steel cage, a feed screw cap (6), a screw cap control device and an ejection initiating cylinder (24), wherein the ejection steel cage is slidingly installed in the steam pressure maintaining steel cylinder (19); a steam inlet (17) is provided on the steam pressure maintaining steel cylinder (19); a feed inlet (27) is provided at the upper end of the ejection steel cage; the lower end of the ejection steel cage is fixedly installed with a piston rod of the ejection initiating cylinder (24); the feed screw cap (6) is installed on the feed port (27) of the ejection steel cage; and the screw cap control device is installed on the steam pressure maintaining steel cylinder (19) above the feed screw cap (6). The garbage disposer has a simple structure, convenient loading and high-pressure resistance, is suitable for instantaneous ejection, and has uniform and ordered discharge and a more stable ejection slide during steam ejection.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

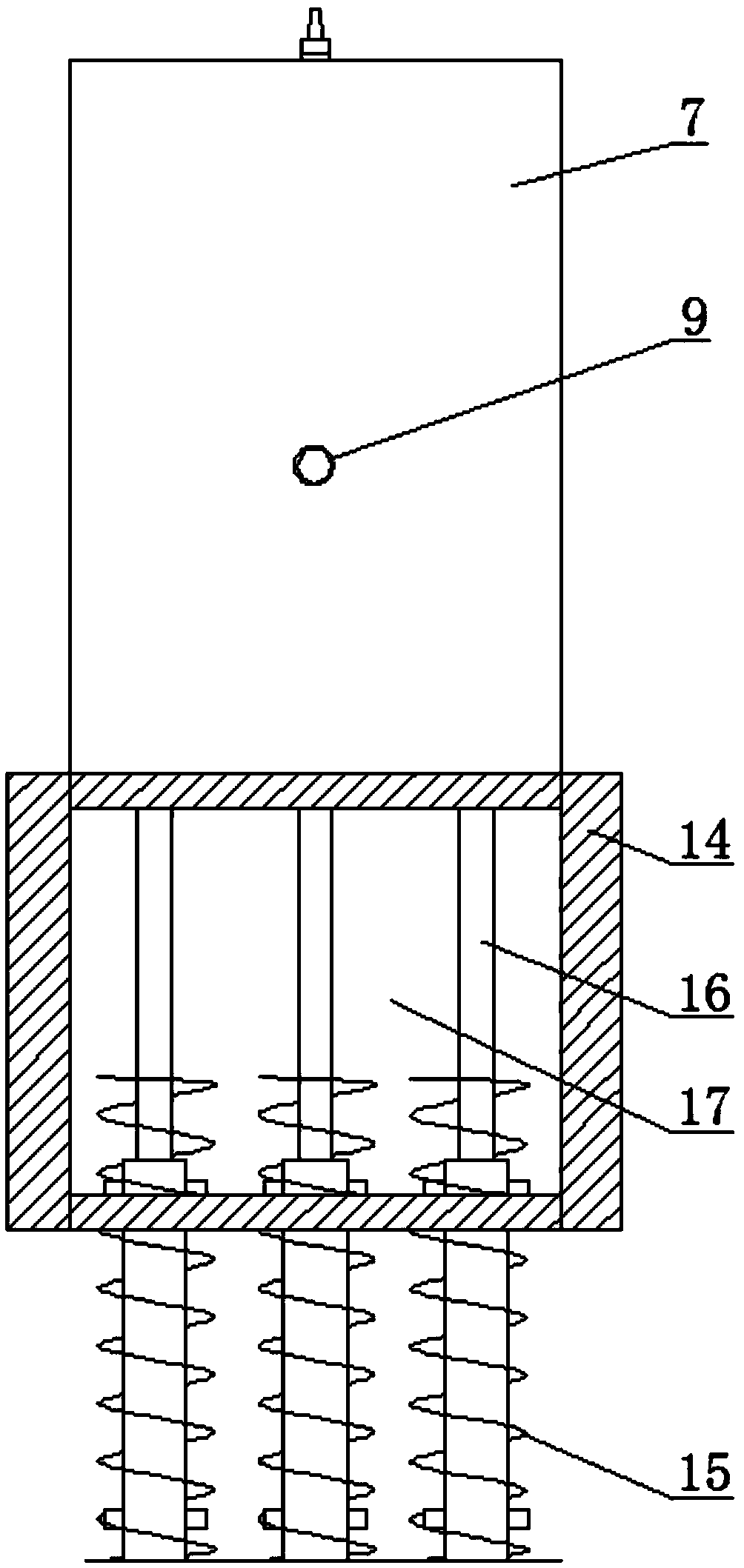

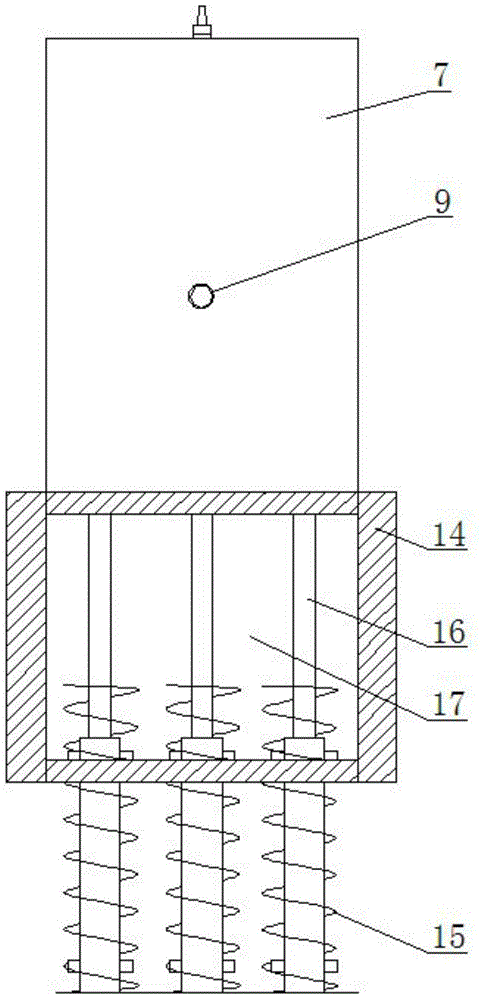

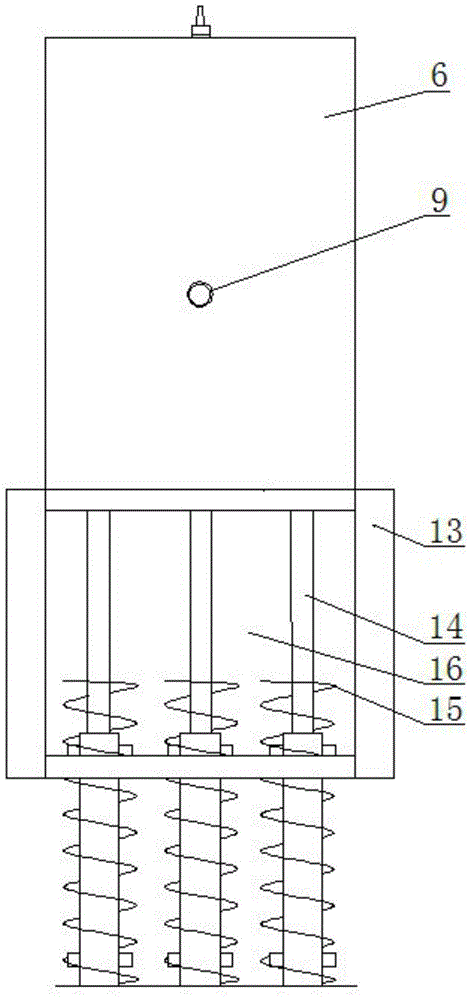

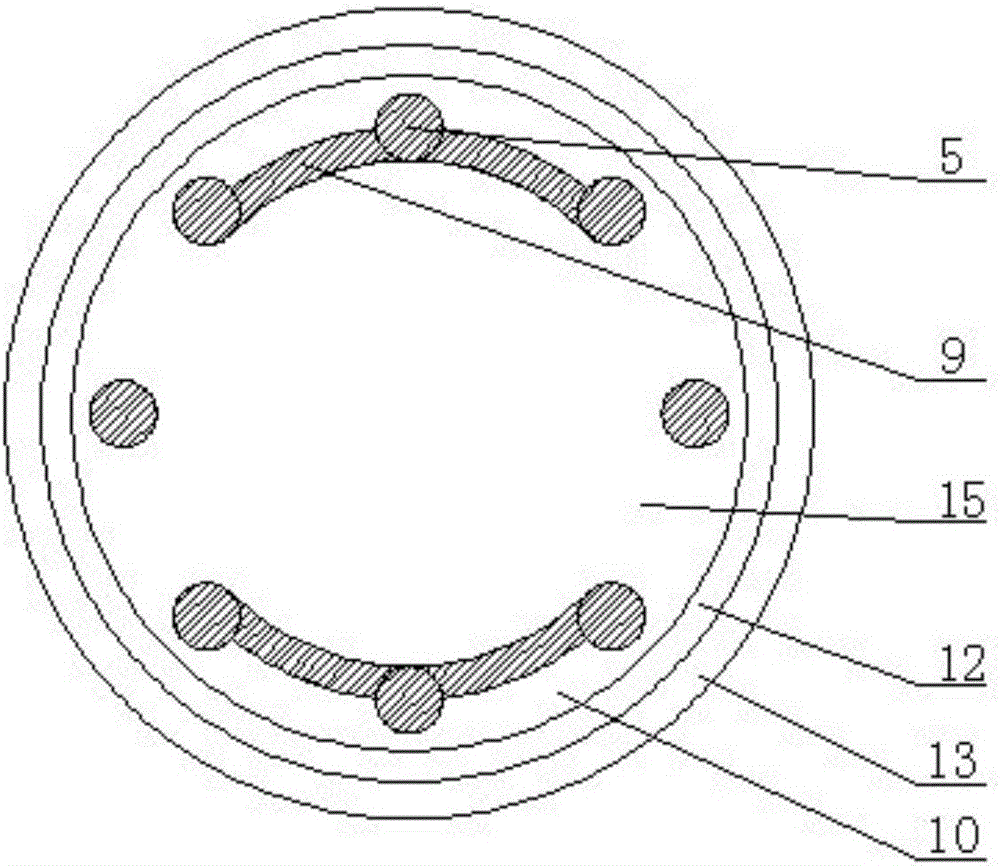

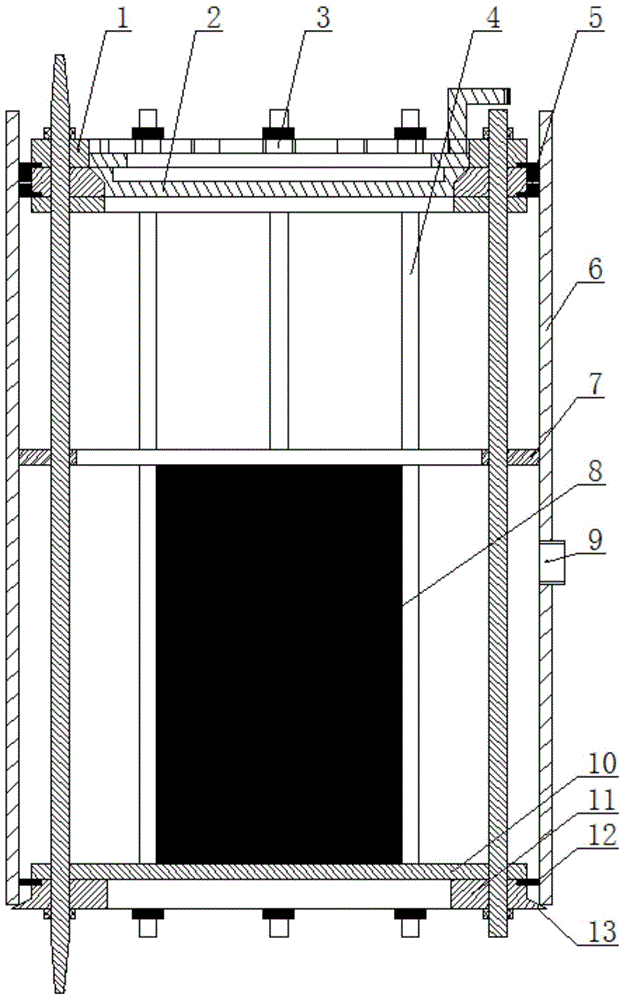

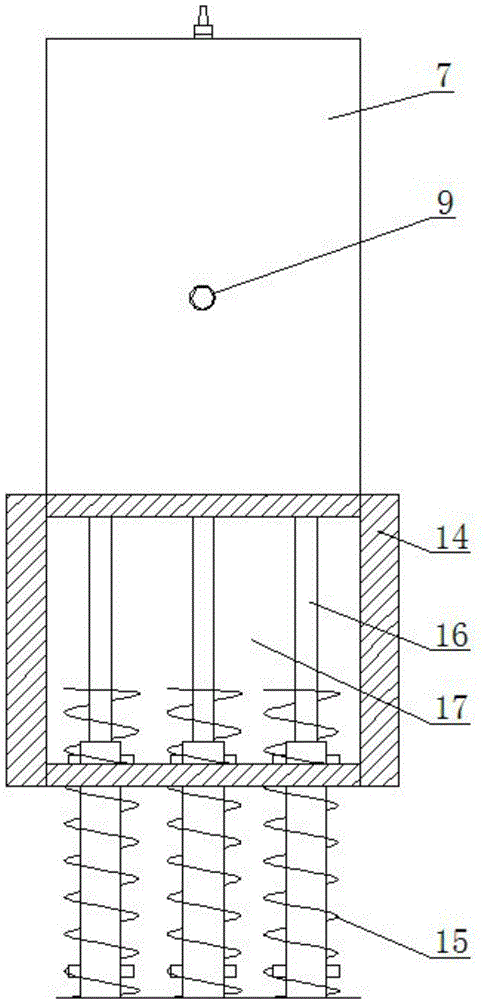

Screw cap provided ejection steel cage for steam ejection type organic waste disposer

PendingCN103406342AEasy feedingStable supportSolid waste disposalTransportation and packagingEngineeringHigh pressure

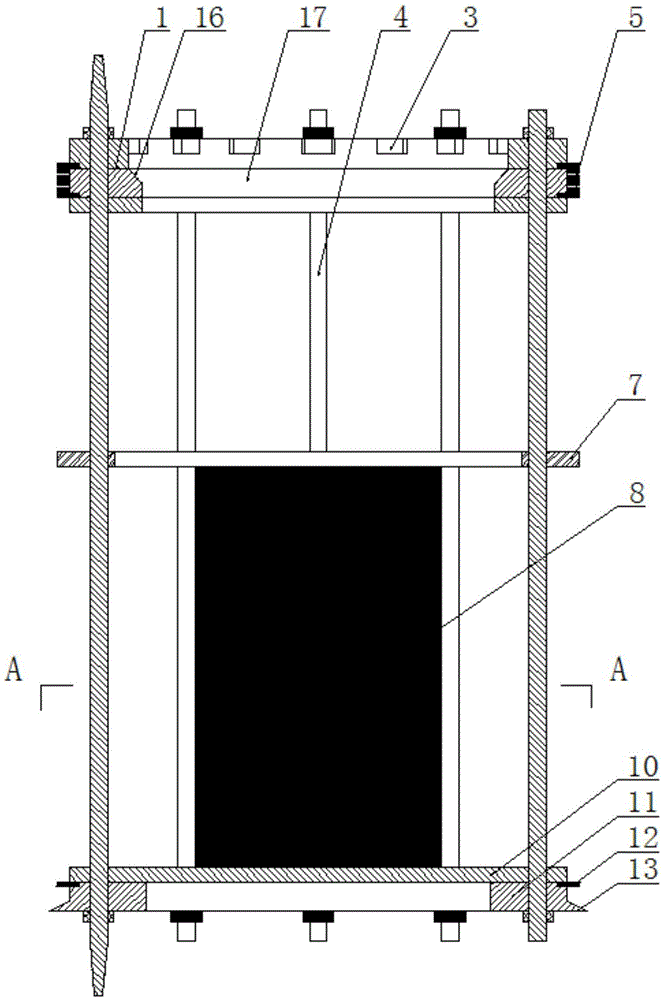

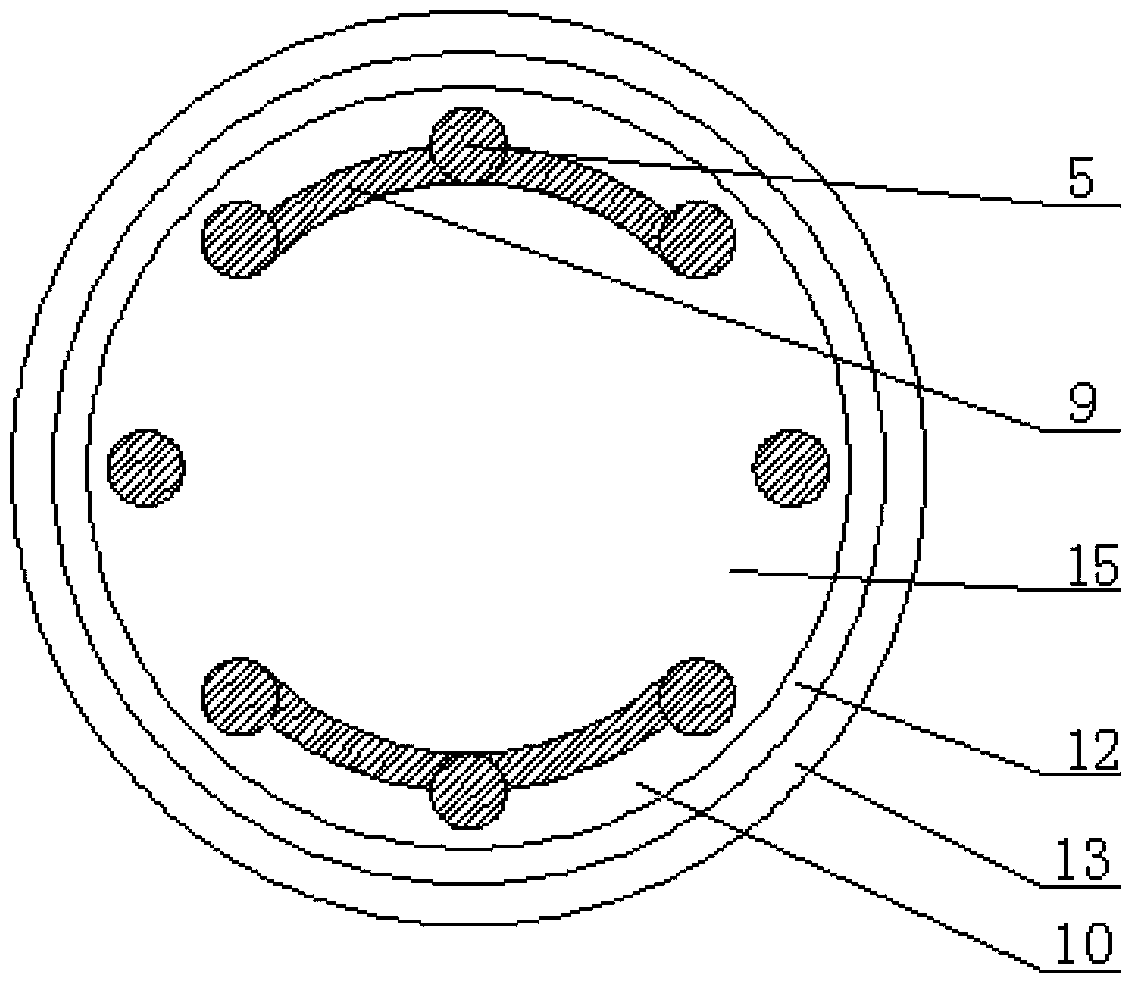

The invention relates to a screw cap provided ejection steel cage for a steam ejection type organic waste disposer. The steel cage comprises an upper sliding disk, a lower sliding disk and support pillars, wherein the support pillars are fixedly installed between the upper and lower sliding disks; a feeding hole is formed in the upper sliding disk; a feeding screw cap is installed to be matched with the feeding hole; material opening limiting teeth are uniformly distributed at the upper edge of the inner wall of the feeding hole; material opening sealing skew walls are arranged on the inner wall of the feeding hole, below the material opening limiting teeth; screw cap locking teeth are arranged on the feeding screw cap corresponding to the material opening limiting teeth; screw cap sealing skew walls are arranged on the feeding screw cap corresponding to the material opening sealing skew walls; and the support pillars are uniformly distributed and fixedly installed between the upper sliding disk on the periphery of the feeding hole and the lower sliding disk. The steel cage has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength, is convenient for loading, is uniform and orderly in discharging when undergoing steam ejection, and is more stable in sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Organic substance garbage disposer with steam-solid separator

InactiveCN104722565AEasy feedingSmooth feedingSolid waste disposalSteam pressurePulp and paper industry

The invention relates to an organic substance garbage disposer with a steam-solid separator, which comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap, an ejection initiating cylinder, a discharge guide cylinder and the steam-solid separator, wherein the ejection steel cage is arranged in the steam pressure maintaining steel cylinder in a sliding manner, the upper end of the ejection steel cage is provided with a feed inlet, the lower end of the ejection steel cage is fixedly connected with a piston rod of the ejection initiating cylinder, the feeding screw cap is arranged at the feed inlet of the ejection steel cage, the lower end of the steam pressure maintaining steel cylinder is connected with the steam-solid separator by the discharge guide cylinder, a steam inlet is formed in the steam pressure maintaining steel cylinder, support pillars are fixedly arranged and uniformly distributed between an upper sliding disk and a lower sliding disk at the periphery of the feed inlet, and the bottom of the lower sliding disk is fixedly connected with the piston rod of the ejection initiating cylinder. The organic substance garbage disposer disclosed by the invention is simple in structure, high pressure resistant and high in strength, facilitates material loading, and adapts to instantaneous ejection; and in the process of steam ejection, discharging is uniform and orderly, steam and slurry materials are effectively separated, and ejection sliding is smooth and steady.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Fertilizer making system of organic matter waste treatment machine provided with ejection steel keel

PendingCN104710200ALarge amount of processingImprove fertilizer efficiencyClimate change adaptationOrganic fertilisersKeelOperability

The invention relates to a fertilizer making system of an organic matter waste treatment machine provided with an ejection steel keel. A charging robot is connected with an inlet of a broken bag drum screening machine through a conveying machine; an outlet of the broken bag drum screening machine is connected with an inlet of a permanent magnetic separation machine; an outlet of the permanent magnetic separation machine is connected with an inlet of an air separation machine; the air separation machine is connected with the steam ejection type organic matter waste treatment machine; the steam ejection type organic matter waste treatment machine is connected with an inlet of a drum-type drying machine; an outlet of the drum-type drying machine is connected with an inlet of a drum pre-cleaner through the conveying machine; the drum pre-cleaner is connected with organic fertilizer production equipment through the conveying machine; the steam ejection type organic matter waste treatment machine comprises a system frame, a pressure-maintaining ejection device, a pressure-maintaining ejection device screw cap controller, a liftable conveying hopper, a charging lifting device, a discharging guide barrel and a steam-solid separator. The fertilizer making system is short in fertilizer making time, large in waste treatment amount, high in fertilizer efficiency, convenient for production and strong in operability, solves problems of environmental pollution and ecological hazard caused by wastes, and realizes cyclic utilization and environmental protection.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Fertilizer preparation system of organic solid waste processor with limiting bevel edge

PendingCN104692841ALarge amount of processingImprove fertilizer efficiencyClimate change adaptationOrganic fertilisersWaste processingMagnetic separator

The invention relates to a fertilizer preparation system of an organic solid waste processor with a limiting bevel edge. A loading robot is connected with the inlet of a bag breaking roller screening machine through a conveyer, the outlet of the bag breaking roller screening machine is connected with the inlet of a permanent magnetic separator, the outlet of the permanent magnetic separator is connected with the inlet of a winnower, the winnower is connected with the steam ejection type organic solid waste processor which is connected with the inlet of a roller drier, the outlet of the roller drier is connected with the inlet of a cylinder initial screen through a conveyer, the cylinder initial screen is connected with organic fertilizer production equipment through a conveyer, and the steam ejection type organic solid waste processor comprises a system frame, a pressure-maintaining ejection device, a spin cover controller of the pressure-maintaining ejection device, a liftable feeding funnel, a loading lifting device, a discharging guide cylinder and a steam-solid separator. The system provided by the invention is short in fertilizer preparation time, great in waste processing amount, high in fertilizer efficiency, convenient to produce and strong in operability, can be used for solving the problems that wastes pollute the environment and harm ecology and realizing cyclic utilization and is environmentally friendly.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

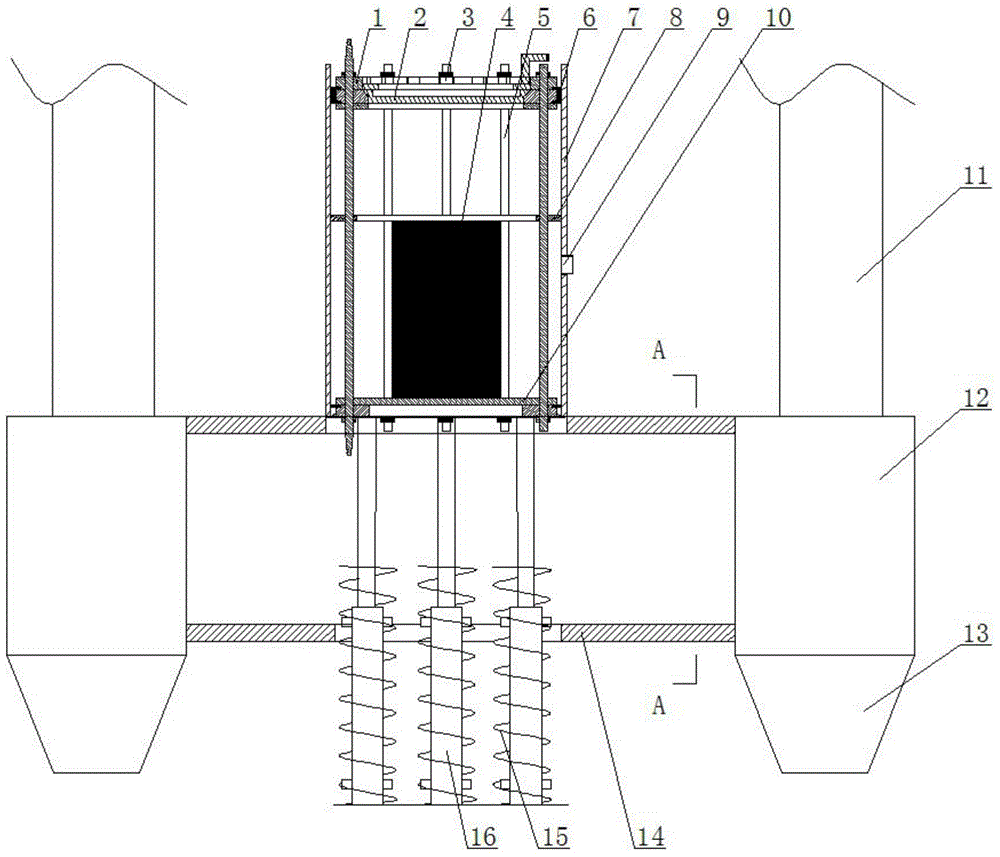

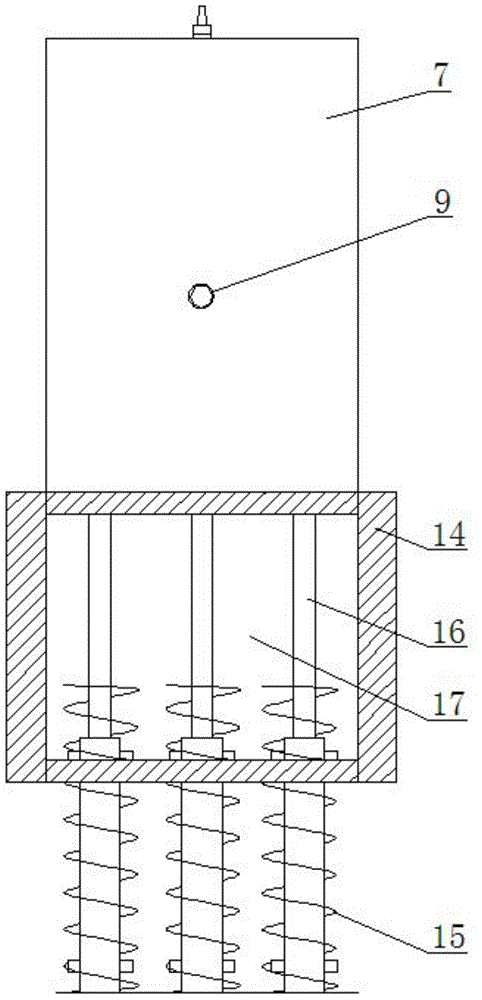

Pressure maintaining ejection device for steam ejection type organic waste disposer

ActiveCN103406335ASmooth feedingIncrease the feeding speedSolid waste disposalSteam pressureHigh pressure

The invention relates to a pressure maintaining ejection device for a steam ejection type organic waste disposer. The device comprises a steam pressure maintaining steel cylinder, an ejection steel cage and a feeding screw cap, wherein the ejection steel cage is installed in the steam pressure maintaining steel cylinder in a sliding manner and comprises an upper sliding disk, a lower sliding disk and support pillars; a feeding hole is formed in the upper sliding disk; the feeding screw cap is installed to be matched with the feeding hole; material opening limiting teeth are uniformly distributed at the upper edge of the inner wall of the feeding hole; material opening sealing skew walls are arranged on the inner wall of the feeding hole, below the material opening limiting teeth; screw cap locking teeth are arranged on the feeding screw cap corresponding to the material opening limiting teeth; screw cap sealing skew walls are arranged on the feeding screw cap corresponding to the material opening sealing skew walls; and the support pillars are uniformly distributed and fixedly installed between the upper sliding disk on the periphery of the feeding hole and the lower sliding disk. The device has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength and is convenient for loading. A steel cage structure is uniform and orderly in discharging when undergoing steam ejection. The steel cage is more stable in sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Pressure-holding ejection structure for steam ejection organic waste disposer

ActiveCN103433269BEasy feedingIncrease the feeding speedSolid waste disposalTransportation and packagingSlurry wallSteam pressure

The invention relates to a pressure-holding ejection device for a steam-ejection type organic waste disposer, which comprises a steam-holding steel cylinder, an ejection steel cage and a feeding screw cap, the ejection steel cage is slidably installed in the steam pressure-holding steel cylinder, and the ejection steel The cage includes an upper sliding plate, a lower sliding plate and a support column. A feeding port is made on the upper sliding plate, and a feeding screw cap is installed to match the feeding port. , the inner wall of the feed port below the limit tooth of the feed port is formed with a sealing inclined wall of the feed port, and the feed screw cap corresponding to the stop tooth of the feed port is formed with a cap locking tooth, which is connected with the inclined wall of the sealing port of the feed port. The corresponding feeding screw cap is formed with a screw cap sealing inclined wall, and fixed support columns are uniformly arranged between the upper sliding plate and the lower sliding plate on the periphery of the feeding port. The invention has the advantages of simple structure, adaptability to instantaneous ejection, high pressure resistance, high strength, and convenient feeding. When the steel cage structure is ejected by steam, the steel cage structure is evenly and orderly discharged, and the steel cage slides more smoothly.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam ejecting type organic garbage disposer with limiting inclined edge

The invention relates to a steam ejecting type organic garbage disposer with a limiting inclined edge. The steam ejecting type organic garbage disposer comprises a steam pressure-maintaining steel cylinder, an ejecting steel cage, a feed screw cover and an ejection triggering air cylinder, wherein the ejecting steel cage is slidably arranged in the steam pressure-maintaining steel cylinder; the steam pressure-maintaining steel cylinder is provided with a steam inlet; the upper end of the ejecting steel cage is provided with a feed opening, and the lower end of the ejecting steel cage is fixed with a piston rod of the ejection triggering air cylinder; the feed screw cover is arranged on the feed opening of the ejecting steel cage; the lower end of the steam pressure-maintaining steel cylinder is provided with a discharge guide cylinder, the ejection triggering air cylinder penetrates through the discharge guide cylinder, and two ends of the discharge guide cylinder are provided with guide discharge openings; the ejecting steel cage comprises an upper sliding disc, a lower sliding disc and a support column; and the upper sliding disc is provided with the feed opening, the feed screw cover is arranged by being matched with the feed opening, and material opening limiting teeth are uniformly distributed on the upper edge of the inner wall of the feed opening. The steam ejecting type organic garbage disposer disclosed by the invention has the advantages of simple structure, suitability for instant ejection, high pressure resistance, high strength, convenience for feeding, uniformity and orderliness in discharge during steam ejection and more smoothness in ejection sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

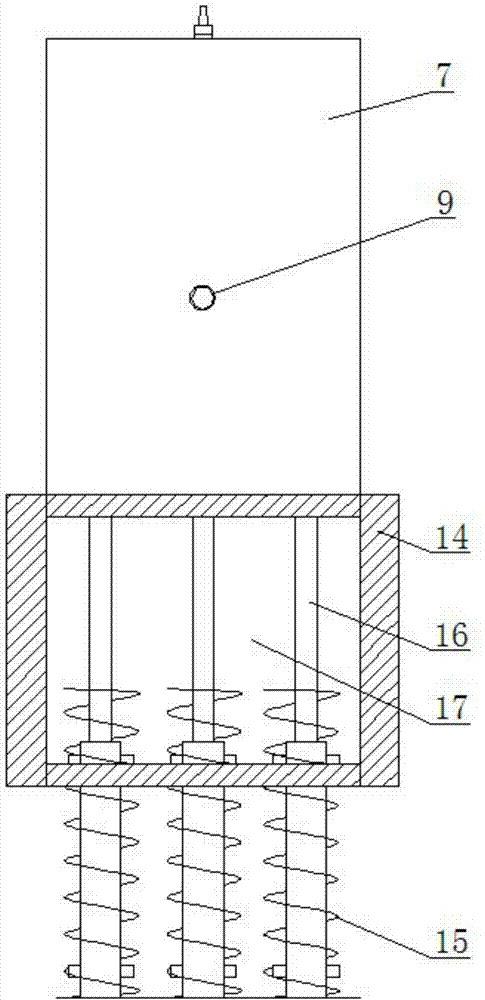

Organic matter garbage disposal system provided with slide guide ring

InactiveCN105921485AEasy feedingIncrease the feeding speedSolid waste disposalTransportation and packagingSystems designLitter

The invention relates to an organic matter garbage disposal system provided with a slide guide ring. The organic matter garbage disposal system provided with the slide guide ring comprises a system framework, a pressure-maintaining ejection device, a pressure-maintaining ejection device screw cap controller, a lifting feed hopper, a loading lifting device, a discharge guide cylinder and steam solid separators. The pressure-maintaining ejection device, the pressure-maintaining ejection device screw cap controller and the lifting feed hopper are sequentially installed inside the system framework from bottom to top. The loading lifting device is installed on one side of the system framework. The discharge guide cylinder is installed on the lower portion of the pressure-maintaining ejection device and connected with the steam solid separators. The organic matter garbage disposal system provided with the slide guide ring is scientific and reliable in design, suitable for instantaneous ejection, resistant to high pressure and high in strength; loading can be conducted conveniently; and in the process of steam ejection, discharge is even and orderly and ejection sliding is more stable.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Organic matter rubbish disposer ejecting steel cage with silicon seals

The invention relates to an organic matter rubbish disposer ejecting steel cage with silicon seals. The steel cage comprises an upper sliding plate, a lower sliding plate and supporting columns. The supporting columns are fixedly installed between the upper sliding plate and the lower sliding plate. A material inlet is formed in the upper sliding plate. The supporting columns are evenly distributed and fixedly installed between the part, on the periphery of the material inlet, of the upper sliding plate and the lower sliding plate. The steel cage is simple in structure, suitable for instant ejection, resistant to high pressure and high in strength and facilitates charging; and during vapor ejection of the steel cage structure, the steel cage structure is even and ordered in discharging, and the steel cage slides more steadily.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Gas-solid separating garbage disposal machine provided with sliding guiding rings

The invention relates to a gas-solid separating garbage disposal machine provided with sliding guiding rings. According to the machine, a feed inlet is formed in the upper end of an ejection steel cage, the lower end of the ejection steel cage and a piston rod of an ejection triggering cylinder are fixed together, a feeding screw cap is installed on the feed inlet of the ejection steel cage, a gas-solid separator is connected to the lower end of a steam pressure maintaining steel cylinder through a discharging guiding cylinder, a steam inlet is formed in the steam pressure maintaining steel cylinder, supporting pillars are evenly and fixedly installed between an upper sliding disc and a lower sliding disc around the feed inlet, the bottom of the lower sliding disc and the piston rod of the ejection triggering cylinder are fixed together, the sliding guiding rings are arranged on the middle portions of the supporting pillars, an upper sealing rubber ring is fixedly installed on the outer wall of the upper sliding disc, and a lower sealing rubber ring is fixedly installed on the outer wall of the lower sliding disc. The machine is simple in structure, adaptable to instant ejection, resistant to high pressure and high in strength, feeding is convenient, discharging is even and orderly during steam ejection, steam and slurry can be effectively separated, and ejection sliding is more stable.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam ejection type organic waste disposer with discharge guide holes

ActiveCN103406334BEasy feedingSmooth feedingSolid waste disposalTransportation and packagingSteam pressurePulp and paper industry

Disclosed is a steam ejection type organic garbage disposer with discharge guiding ports, which comprises a steam pressure maintaining steel cylinder (6), an ejection steel cage, a feed screw cap (2) and an ejection initiating cylinder (14), wherein the ejection steel cage is slidingly installed in the steam pressure maintaining steel cylinder (6); a steam inlet (9) is provided on the steam pressure maintaining steel cylinder (6); a feed inlet (19) is provided at the upper end of the ejection steel cage; the lower end of the ejection steel cage is fixedly installed with a piston rod of the ejection initiating cylinder; the feed screw cap (2) is installed on the feed port of the ejection steel cage; a discharge guiding cylinder is installed at the lower end of the steam pressure maintaining steel cylinder (6); and the ejection initiating cylinder passes through the discharge guiding cylinder, and a discharge guiding port (16) is arranged at each of the two ends of the discharge guiding cylinder. The steam ejection type organic garbage disposer with discharge guiding ports is suitable for instantaneous ejection, has high-pressure resistance, high strength and convenient loading, and has uniform and ordered discharge and a more stable ejection slide during steam ejection.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Vapor-solid separation garbage disposal machine with circular groove feed screw cap

The invention relates to a steam ejection type organic garbage processor with a steam-solid separation function. The steam ejection type organic garbage processor comprises a steam pressure maintaining steel cylinder, an ejection steel cage, a feeding screw cap, an ejection trigger cylinder, a discharge guide cylinder and a steam-solid separator, wherein the ejection steel cage is arranged in the steam pressure maintaining steel cylinder in a sliding way; the upper end of the ejection steel cage has a feeding hole; the lower end of the ejection steel cage is fixed with a piston rod of the ejection trigger cylinder; the feeding screw cap is arranged on the feeding hole of the ejection steel cage; the lower end of the steam pressure maintaining steel cylinder is connected with the steam-solid separator by the discharge guide cylinder; the steam pressure maintaining steel cylinder is provided with a steam inlet. The steam ejection type organic garbage processor is simple in structure, can adapt to instantaneous ejection, is high pressure resistant, high in strength and convenient in feeding, is even and orderly in discharging during steam ejection, can effectively separate the steam from slurry material, and is more stable in ejection and slide.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Rapid Fertilizer System Using Household Garbage

InactiveCN103420690BShort throughputLarge amount of processingProductsBio-organic fraction processingAgricultural scienceAgricultural engineering

The invention relates to a system for rapidly making fertilizer using household waste. The system comprises a feeding robot, a bag-breaking drum screening machine, a permanent magnetic separator, a winnowing machine, a steam ejection-type organic waste disposer, a drum drier, a cylinder pre-cleaning screen, a conveyor and organic fertilizer production equipment. The feeding robot is connected with an inlet of the bag-breaking drum screening machine through the conveyor, an outlet of the bag-breaking drum screening machine is connected with an inlet of the permanent magnetic separator, an outlet of the permanent magnet magnetic separator is connected with an inlet of the winnowing machine, the winnowing machine is connected with the steam ejection-type organic waste disposer, which is connected with an inlet of the drum drier, an outlet of the drum drier is connected with an inlet of the cylinder pre-cleaning screen through the conveyor, and the cylinder pre-cleaning screen is connected with the organic fertilizer production equipment through the conveyor. The present invention features a short fertilizer-making time, a large waste throughput, a high fertilizer efficiency, convenient production, high operability, effectively solves the problems that the waste pollutes the environment and harms the ecology, realizes recycling, and is environmentally friendly.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Pressure maintaining ejection device for steam ejection type organic waste disposer

ActiveCN103406335BSmooth feedingIncrease the feeding speedSolid waste disposalThermodynamicsSteam pressure

The invention relates to a pressure maintaining ejection device for a steam ejection type organic waste disposer. The device comprises a steam pressure maintaining steel cylinder, an ejection steel cage and a feeding screw cap, wherein the ejection steel cage is installed in the steam pressure maintaining steel cylinder in a sliding manner and comprises an upper sliding disk, a lower sliding disk and support pillars; a feeding hole is formed in the upper sliding disk; the feeding screw cap is installed to be matched with the feeding hole; material opening limiting teeth are uniformly distributed at the upper edge of the inner wall of the feeding hole; material opening sealing skew walls are arranged on the inner wall of the feeding hole, below the material opening limiting teeth; screw cap locking teeth are arranged on the feeding screw cap corresponding to the material opening limiting teeth; screw cap sealing skew walls are arranged on the feeding screw cap corresponding to the material opening sealing skew walls; and the support pillars are uniformly distributed and fixedly installed between the upper sliding disk on the periphery of the feeding hole and the lower sliding disk. The device has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength and is convenient for loading. A steel cage structure is uniform and orderly in discharging when undergoing steam ejection. The steel cage is more stable in sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Steam-solid separation type waste disposal machine based on arc discharging guide plates

PendingCN104690078AEasy feedingSmooth feedingSolid waste disposalSteam pressurePulp and paper industry

The invention relates to a steam-solid separation type waste disposal machine based on arc discharging guide plates. A rotating feeding cover is installed on a feeding port of a popping-up steel cage. The lower end of a steam pressure-maintaining steel cylinder is connected with steam-solid separators through a discharging guide cylinder. A steam inlet is formed in the steam pressure-maintaining steel cylinder. Supporting columns are evenly and fixedly installed between an upper sliding disk and a lower sliding disk on the periphery of the feeding port, The bottom of the lower sliding disk is fixed to piston rods of popping-up triggering air cylinders. The two discharging guide plates are symmetrically and fixedly installed on the lower portions of the supporting columns and are in arc shape. The two ends, on the same side, of the two discharging arc plates form a steel cage discharging port. The steel cage discharging port corresponds to a guide discharging port of the discharging guide cylinder. The steam-solid separation type waste disposal machine simple in structure, adaptable to instant popping-up, resistant to high pressure and high in strength, feeding is convenient, materials are evenly discharged in order during steam popping up, steam is effectively separated from slurry-state materials, and popping-up sliding is more stable.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Catapulting steel cage with sealing rubber ring and rotary cover

PendingCN105478453AEasy feedingSmooth feedingSolid waste disposalTransportation and packagingRubber ringStructural engineering

The invention relates to a catapulting steel cage with a sealing rubber ring and a rotary cover. The catapulting steel cage comprises an upper sliding disc, a lower sliding disc and supporting columns. The supporting columns are fixedly arranged between the upper sliding disc and the lower sliding disc, a feeding port is formed in the upper sliding disc, the rotary feeding cover is installed on the feeding port in a matched manner, port limiting teeth are evenly distributed on the upper edge of the inner wall of the feeding port, an inclined port sealing wall is manufactured at the portion, below the port limiting teeth, of the inner wall of the feeding port, rotary cover locking teeth are manufactured at the portion, corresponding to the port limiting teeth, on the rotary feeding cover, an inclined rotary cover sealing wall is manufactured at the portion, corresponding to the inclined port sealing wall, on the rotary feeding cover, and the supporting columns are evenly distributed and fixedly arranged at the portion, between the upper sliding disc and the lower sliding disc, on the periphery of the feeding port. The catapulting steel cage is simple in structure, suitable for instant catapulting, resistant to high pressure, high in strength and convenient to feed, and when the steel cage structure is catapulted through steam, the steel cage structure discharges materials evenly in order, and the steel cage slides more smoothly and steadily.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Ejection steel cage for steam ejection type organic waste disposer

The invention relates to an ejection steel cage for a steam ejection type organic waste disposer. The steel cage comprises an upper sliding disk, a lower sliding disk and support pillars, wherein the support pillars are fixedly installed between the upper and lower sliding disks; a feeding hole is formed in the upper sliding disk; and the support pillars are uniformly distributed and fixedly installed between the upper sliding disk on the periphery of the feeding hole and the lower sliding disk. The steel cage has a simple structure, adapts to instantaneous ejection, is resistant to high pressure, has high strength, is convenient for loading, is uniform and orderly in discharging when undergoing steam ejection, and is more stable in sliding.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Ejection steel cage with sliding guide ring and screw cover

PendingCN105478452AEasy feedingSmooth feedingSolid waste disposalTransportation and packagingSlide plateEngineering

The invention relates to an ejection steel cage with a sliding guide ring and a screw cover. The ejection steel ring comprises an upper sliding plate, a lower sliding plate and supporting pillars. The supporting pillars are fixedly arranged between the upper sliding plate and the lower sliding plate. A feeding port is formed in the upper sliding plate. The feeding screw cover is installed in cooperation with the feeding port. Feeding port limiting teeth are evenly distributed on the upper edge of the inner wall of the feeding port. A feeding port sealing inclined wall is manufactured on the part, below the feeding port limiting teeth, of the inner wall of the feeding port. Screw cover locking teeth are manufactured at the positions, corresponding to the feeding port limiting teeth, on the feeding screw cover. A screw cover sealing inclined wall is manufactured at the position, corresponding to the feeding port sealing inclined wall, on the feeding screw cover. The supporting pillars are evenly and fixedly arranged on the part, between the upper sliding plate and the lower sliding plate, of the periphery of the feeding port. The ejection steel cage with the sliding guide ring and the screw cover is simple in structure, capable of adapting to instantaneous injection, resistant to high pressure, large in strength and capable of facilitating feeding, when steam is used for ejecting the steel cage structure, discharging of the steel cage structure is even and orderly, and sliding of the steel cage is more stable.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com