Microelectronic mechanical system structure forming method

A technology of microelectronic machinery and system structure, applied in microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of reduced etching rate, difficult to control, fast etching rate, etc., to improve the removal rate, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

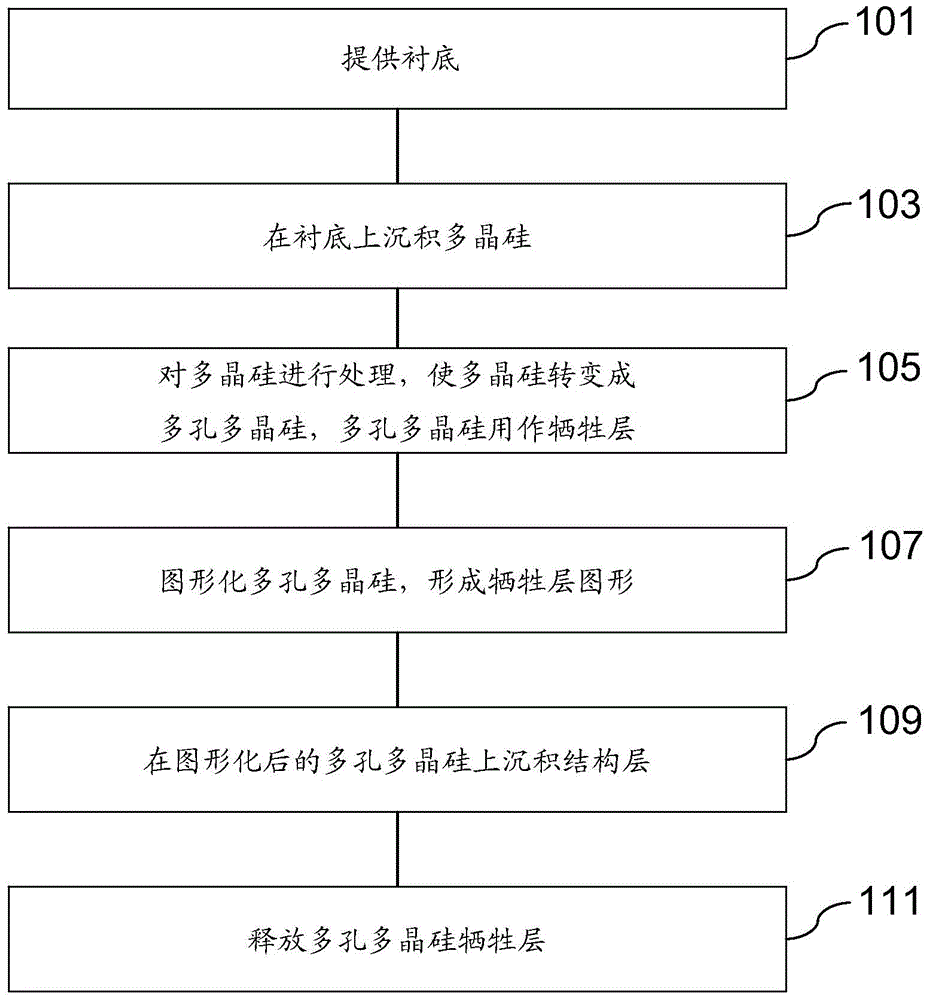

[0013] refer to figure 1 , discloses a flowchart of an embodiment of the MEMS structure forming method of the present invention. The method comprises the steps of:

[0014] Step S101, providing a substrate;

[0015] Step S103, depositing polysilicon on the substrate;

[0016] Step S105, processing the polysilicon to transform the polysilicon into porous polysilicon, and the porous polysilicon is used as a sacrificial layer;

[0017] Step S107, patterning the porous polysilicon to form a sacrificial layer pattern;

[0018] Step S109, depositing a structural layer on the patterned porous polysilicon;

[0019] Step S111 , releasing the porous polysilicon sacrificial layer.

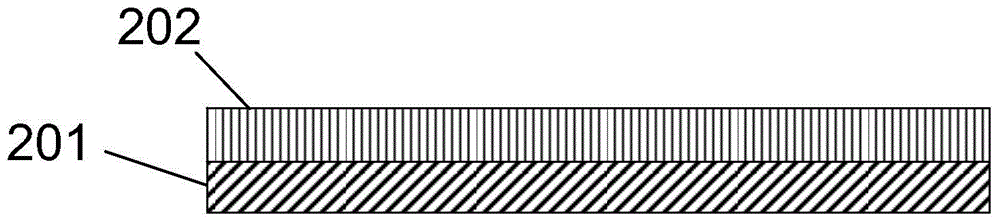

[0020] refer to Figure 2A-2I , reveals a schematic cross-sectional structure corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com