Rare earth catalyst system for preparing high trans-diolefin homopolymer and copolymer and method for catalyzing polymerization of diolefin

A technology of diene polymer and rare earth catalysis, which is applied in the field of rare earth catalyst system and catalytic diene polymerization, to achieve good catalytic activity and facilitate application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The present invention has no special limitation on the preparation method of the rare earth catalytic composition, the rare earth compound, the conjugated diene, the first auxiliary component and the second auxiliary component can be added to an organic solvent such as a hydrocarbon solvent, or first Mix and add organic solvent. For the order of addition, the rare earth compound, the conjugated diene and the second auxiliary component can be mixed in sequence to obtain a rare earth mixture, the first auxiliary component is added to the polymerization liquid, and then the prepared rare earth mixture is added to obtain a rare earth catalytic composition It is also possible to mix the rare earth compound, the conjugated diene, the second auxiliary component and the first auxiliary component successively to obtain a rare earth mixture, and the first auxiliary component is added to the polymerization liquid, and then the prepared rare earth mixture is added to obtain Rare ea...

Embodiment 1

[0103] 1.1 In the reactor, according to the molar ratio of neodymium oxide and trifluoromethanesulfonic acid as 10:1, add neodymium oxide into trifluoromethanesulfonic acid solution, heat to 70°C under stirring conditions, and react for 8 hours. Remove unreacted neodymium oxide by filtration, and concentrate to obtain an aqueous solution of neodymium trifluoromethanesulfonate compound, and then place the concentrated solution at room temperature to naturally precipitate crystals, which are neodymium trifluoromethanesulfonate with crystal water compound.

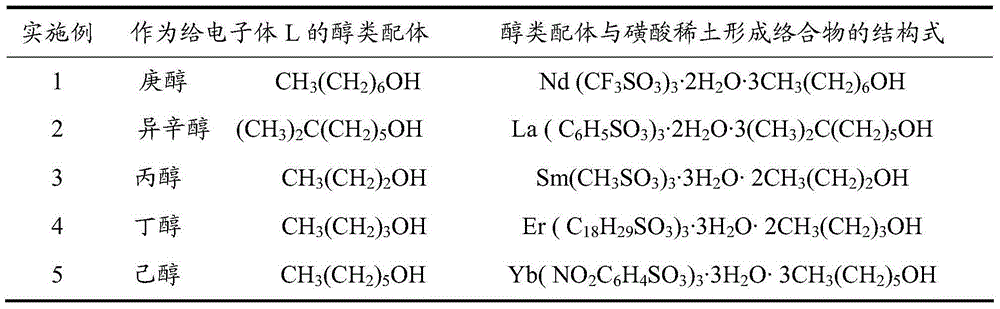

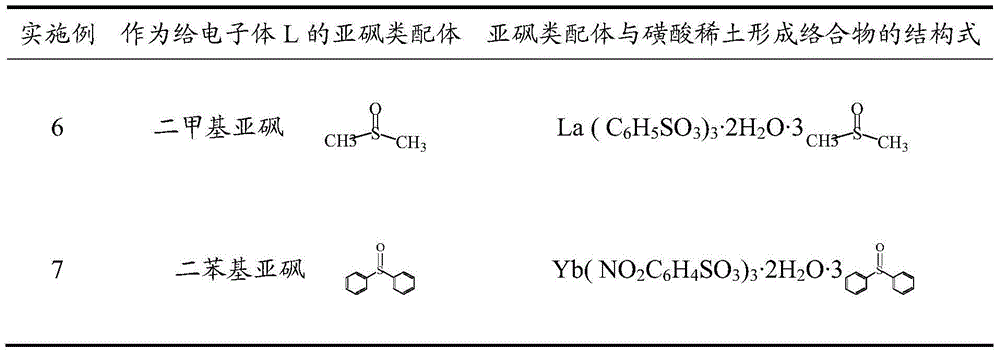

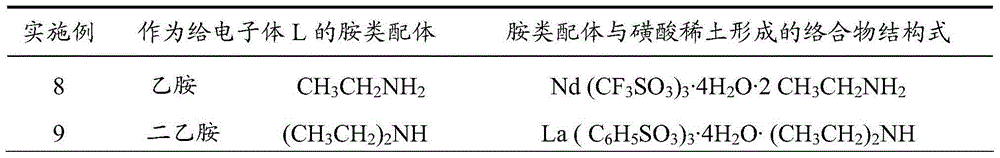

[0104] 1.2 According to the molar ratio of rare earth: electron donor L being 1:3, add the neodymium trifluoromethanesulfonate compound crystal and electron donor L into the reactor respectively, then add 40mL tetrahydrofuran as a solvent, and boil the solution Condensed under reflux for 16 hours, evaporated the solvent, and dried to constant weight to obtain the rare earth compound represented by formula I. For the structur...

Embodiment 2

[0108] 2.1 Add lanthanum oxide to the benzenesulfonic acid solution in the reactor according to the molar ratio of lanthanum oxide to benzenesulfonic acid is 10:1, heat to 80°C under stirring condition, react for 5 hours, filter the untreated The reacted lanthanum oxide is removed and concentrated to obtain an aqueous solution of lanthanum benzenesulfonate compound, and then the concentrated solution is placed at room temperature to naturally precipitate crystals, which are lanthanum benzenesulfonate compounds with crystal water.

[0109] 2.2 According to the ratio of rare earth: electron donor L molar ratio of 1:3, respectively add the lanthanum benzenesulfonate compound crystal and electron donor L into the reactor, then add 40mL tetrahydrofuran as a solvent, in the solution boiling state Condensate and reflux for 16 hours, evaporate the solvent, and dry to constant weight to obtain the rare earth compound shown in formula I. For the structure of the rare earth compound, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com