Hot-melt pressure-sensitive adhesive as well as preparation method thereof and waterproof coiled material

A hot melt pressure sensitive adhesive, raw material technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., to achieve good adhesion, excellent adhesion, excellent adhesion and anti-aging performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

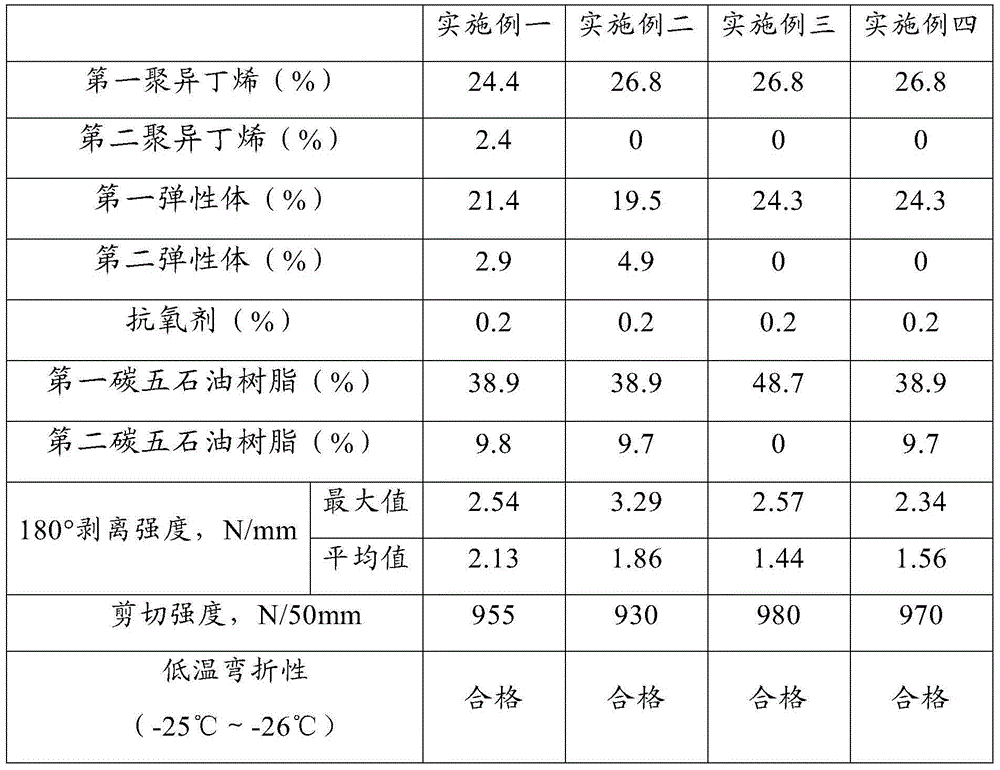

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0038] The invention provides a hot-melt pressure-sensitive adhesive with low-temperature bending property of -25°C without cracks, good holding force and excellent temperature resistance. The hot-melt pressure-sensitive adhesive comprises a first elastomer, a second Made from raw materials of polyisobutylene and the first C5 petroleum resin, the first elastomer is polystyrene-polyisoprene-polystyrene elastomer; the first polyisobutylene is a liquid with molecular weight less than 1000 Polyisobutylene with a pour point of -30°C to -4°C; the first C5 petroleum resin is a solid alicyclic hydrocarbon hydrogenated petroleum resin with a softening point of 100°C to 127°C and an initial color number of 2 or less.

[0039] Wherein, in the raw material, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com