Crystallization aid and fat fractionation method

A technology for crystallizing agent and oil, applied in the direction of oil/fat refining, fat production, etc., can solve the problem that asymmetric triglycerides cannot be easily separated, and achieve the goal of improving the effective utilization value, promoting crystallization and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The preparation method of crystal aid

[0087] Detect the FAC (fatty acid composition) composition of the raw materials, mix the raw materials according to the results of the detected FAC composition, to prepare palmitic acid which accounts for 3-40wt% of the total fatty acid content, and stearic acid which accounts for 30-55wt% of the total fatty acid content %, the glyceride composition whose content of behenic acid accounts for 20-45wt% of the total fatty acid content. It is preferred to prepare a glyceride composition in which the content of palmitic acid accounts for 20-40wt% of the total fatty acid content, the content of stearic acid accounts for 30-45wt% of the total fatty acid content, and the content of behenic acid accounts for 20-35wt% of the total fatty acid content . in:

[0088] 1. Preparation of monoglyceride (MAG): Detect the FAC composition in the raw material monoglyceride, mix the raw material monoglyceride according to the result of the detected F...

Embodiment 1

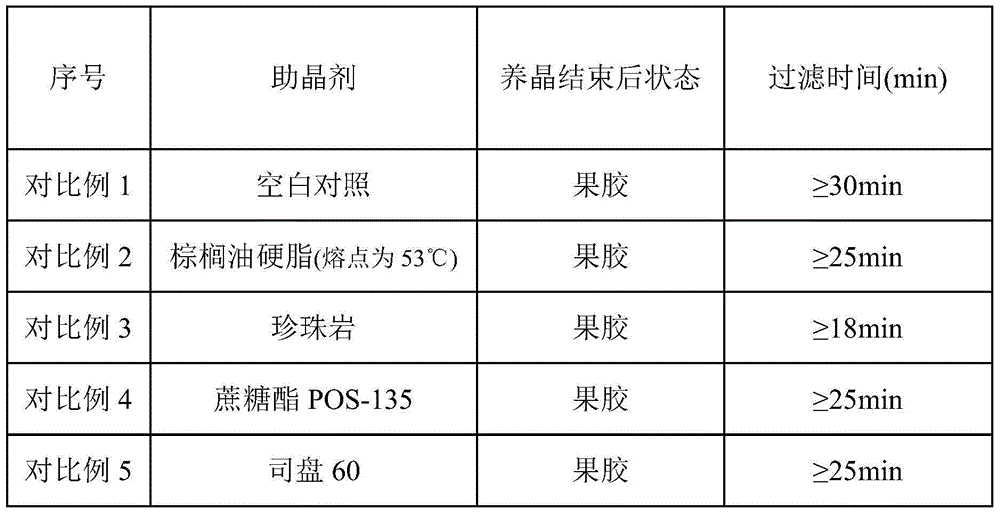

[0102] Embodiment one: dry fractionation experiment

[0103] Add 15L of ordinary peanut oil to a crystallization tank with stirring and jacket, add no crystal aid or add 0.5% crystal aid (listed in Table 1), heat up to 40°C, and stir at 40r / min for 1h; Cool to 8°C, and the stirring rate is 20r / min. The crystal was grown for 6 hours, filtered, and the state after crystal growth and the time of filtration were recorded. The results are shown in Table 1.

[0104] Table 1 Effect of using different crystal aids on oil filtration

[0105]

[0106]

[0107] Note: crystal aid 1-1: the sum of DG content is 0, and its fatty acid composition is C16:0 accounting for 5% of the total fatty acid weight, C18:0 accounting for 49% of the total fatty acid weight, and C22:0 accounting for 40% of the total fatty acid weight %.

[0108] Crystal aid 2-1: the sum of the content of 1,3-diglyceride and 1,2-diglyceride is 20.64%. In this composition, C16:0 fatty acid accounts for 27% of the tot...

Embodiment 2

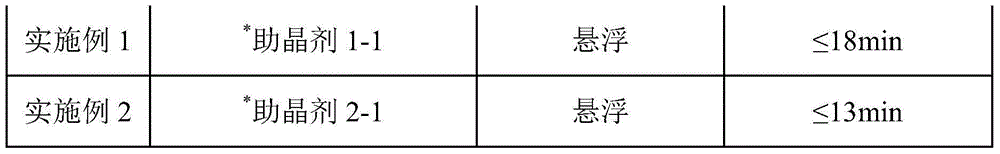

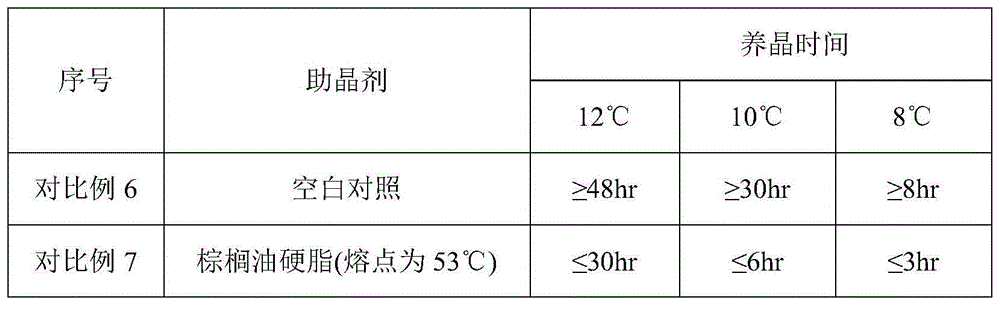

[0110] Embodiment two different crystal growth agents crystal growth time

[0111] Put ordinary peanut oil 15L into a crystallization tank with stirring and jacket. Add no crystal aid or add 0.5% crystal aid (listed in Table 2), heat the temperature to 40°C, keep it for 1h, and stir at 40r / min; cool to 8°C, 10°C, 12°C, and stir at 20r / min. The crystal growth time was recorded, and the results are shown in Table 2.

[0112] Table 2 Growth time of different crystal additives

[0113]

[0114]

[0115] From the data in Table 2, it can be seen that when the crystal growth temperature is 8°C, except for sucrose ester, the crystal growth time required for other crystal growth agents is less than 10h, especially when the crystal growth agent 2 and palm stearin are used. The crystal growth time is less than 3h. As the crystal growth temperature increases, the required crystal growth time increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com