Preparation method of composite electrolyte sheet

A composite electrolyte, alumina sheet technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as difficult operation, difficulty, and inability to practical application, and achieve improved strength, low ion resistance, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

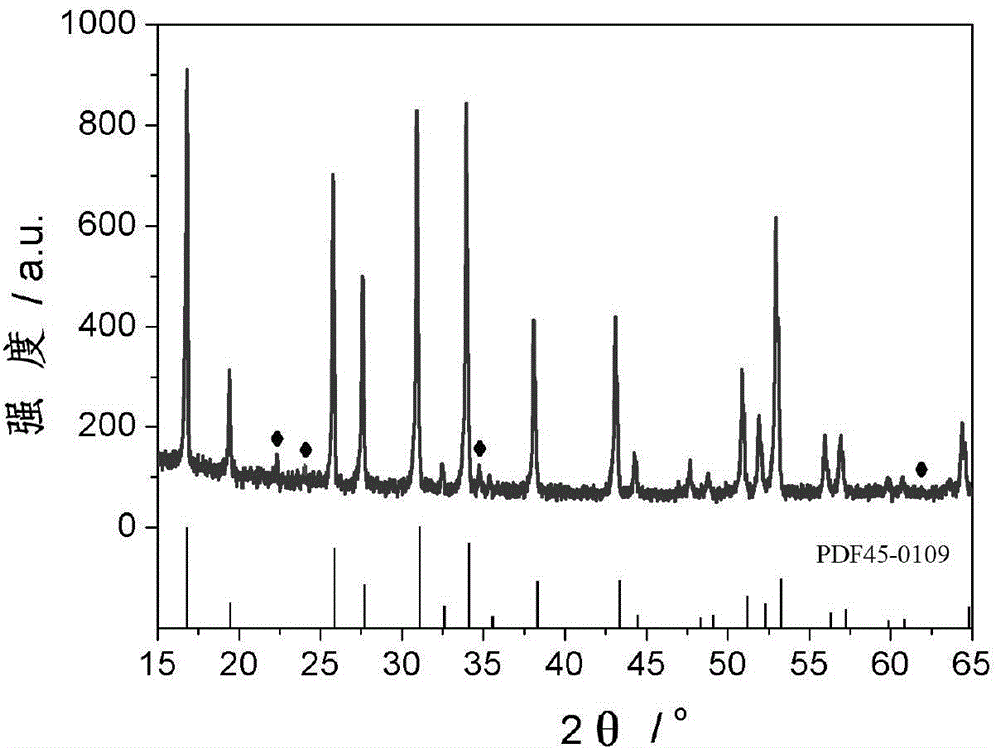

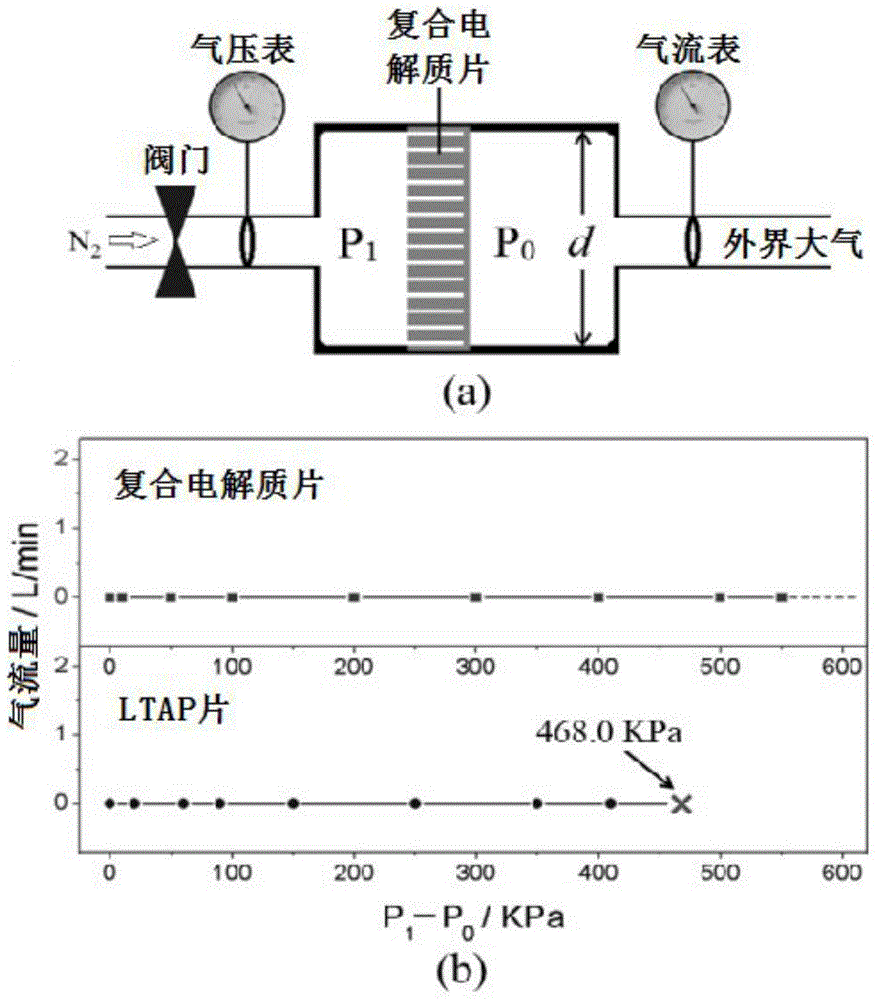

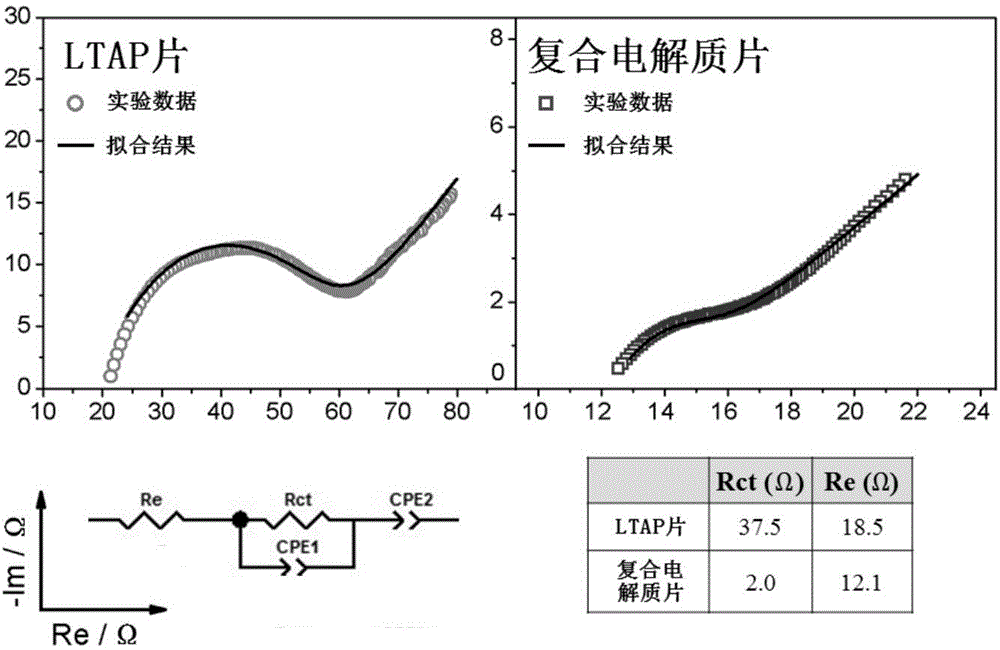

Embodiment 1

[0021] A method for preparing a composite electrolyte sheet, comprising the following steps:

[0022] 1) Preparation of honeycomb alumina sheet: prepared by freeze-casting method, weighing 85.0g of alumina powder, adding 100.0g of tert-butanol, 0.5g of PVB powder, 4.5g of BYK163 dispersant, 4.0g of deionized water g, ball milled for 4 hours, vacuumize the obtained slurry to defoam and pour it into a mold. The bottom of the mold is a copper plate, and the surrounding is made of nylon plastic material. Then put it on a -70°C freezer for 5 hours, and then -40°C Vacuum freeze-drying at ℃, after demoulding, the alumina green cylinder with straight through holes is obtained, and sintered at 1720℃ for 2 hours to obtain the alumina cylinder with straight through holes, and finally cut with a low-speed precision cutting machine to obtain a thickness of 1mm and a diameter of 19mm Honeycomb alumina sheet, with an average pore size of 61 μm and a porosity of 64%;

[0023] 2) Preparation ...

Embodiment 2

[0033] A method for preparing a composite electrolyte sheet, comprising the following steps:

[0034] 1) Preparation of honeycomb alumina sheet: prepared by freeze-casting method, weighing 100.0g of alumina powder, adding 100.0g of tert-butanol, 0.6g of PTFE powder, 5.0g of triolein dispersant, 4.0g of deionized water, ball milled for 6 hours, inject the obtained slurry into the mold, the bottom of the mold is a copper plate, and the surrounding is made of nylon plastic material, and then put them together on the freezing table, freeze and shape on the freezing table at -100°C for 5 hours, Then vacuum freeze-dry at -40°C. After demoulding, the alumina green cylinder with straight through holes is obtained. Sinter at 1680°C for 4 hours to obtain the alumina cylinder with straight through holes. Finally, cut it with a low-speed precision cutting machine to obtain a thickness of 1mm. 1. A honeycomb aluminum oxide sheet with a diameter of 19mm, an average pore diameter of 46μm, an...

Embodiment 3

[0039] A method for preparing a composite electrolyte sheet, comprising the following steps:

[0040] 1) Preparation of honeycomb alumina sheet: prepared by freeze-casting method, weighing 85.0g of alumina powder, adding 100.0g of tert-butanol, 0.5g of PVB powder, 4.5g of BYK163 dispersant, 4.0g of deionized water g, ball milled for 4 hours, vacuumize the obtained slurry to defoam and pour it into a mold. The bottom of the mold is a copper plate, and the surrounding is made of nylon plastic material. Then put it on a -70°C freezer for 5 hours, and then -40°C Vacuum freeze-drying at ℃, after demoulding, the alumina green cylinder with straight through holes is obtained, and sintered at 1720℃ for 2 hours to obtain the alumina cylinder with straight through holes, and finally cut with a low-speed precision cutting machine to obtain a thickness of 1mm and a diameter of 19mm Honeycomb alumina sheet, with an average pore size of 61 μm and a porosity of 64%;

[0041] 2) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com