Hollow core-shell Pt@Ni/graphene three-dimensional composite catalyst and preparation method

A three-dimensional composite, graphene technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the difficult controllable preparation of composite catalyst particles, reaction time long, high reaction temperature, etc., to achieve the effect of increasing the effective specific surface area, improving the utilization rate, and improving the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

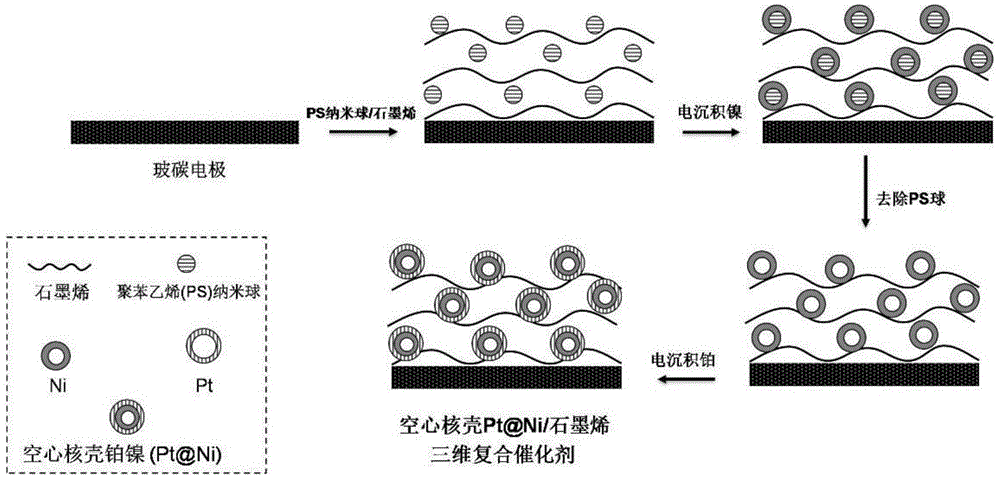

[0030] 1) Weigh 2 mg of graphene and disperse it in 2 ml of deionized water, ultrasonically in an ultrasonic cleaner for 12 hours to obtain a 1.0 mg / ml graphene suspension, then add 40 μL (200 nm in diameter) of 2.5 wt% polystyrene (PS) latex nano Spherical water dispersion, ultrasonic cleaning machine ultrasonic 20min, obtain PS nanosphere / graphene homogeneous suspension.

[0031] 2) Pipette 3 μL of the above-mentioned PS nanosphere / graphene homogeneous suspension and drop-coat it on the surface of the glassy carbon electrode, and let it dry naturally to prepare a PS nanosphere / graphene three-dimensional composite modified electrode.

[0032] 3) Connect the saturated calomel electrode, platinum wire electrode and PS nanosphere / graphene modified electrode to the electrochemical workstation, immerse in 1mmol / L nickel nitrate solution, and perform cyclic voltammetry in the range of -0.8 ~ 1.2V Scanning (scanning speed is 50mV / s), scanning 10 circles, so that metal Ni is deposite...

Embodiment 2

[0036] The preparation method is the same as in Example 1, except that polypyrrole PPY nanospheres are used instead of polystyrene (PS) latex nanospheres.

Embodiment 3

[0038] The preparation method is the same as that in Example 1, except that polystyrene (PS) latex nanospheres are replaced by polyvinylpyrrolidone PVP nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com