A method for producing high-activity iron powder by utilizing industrial waste iron slime

A kind of scrap iron sludge, high activity technology, applied in the direction of recycling technology, reducing gas emissions, etc., can solve the problems of complex process, long production cycle, complex process, etc., to achieve simple process, good product performance, easy to store and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

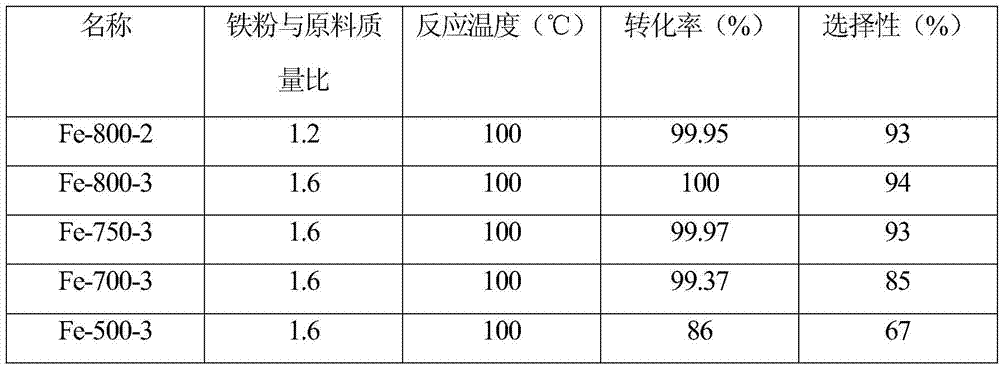

[0020] Embodiment 1: get the iron mud of a certain amount of m-nitrobenzenesulfonic acid reduction process [document 1: Li Liang, Liang Qiuxia, Liu Wei, etc., the synthetic method and industrial production process of m-nitrobenzenesulfonic acid, fine chemical intermediate , 2010, 40(3):8-11], washed with water until the pH value of the filtrate was 7, and then dried the solid matter at 100°C for 12 hours. Take 20g of dry iron sludge and 1g of silicon dioxide, mix them evenly and put them into the reduction reactor, feed hydrogen gas at a flow rate of 20mL / min, and raise the temperature from room temperature to 800°C at a constant speed in 1 hour to carry out the reduction reaction for 2 hours. Then cool to 150°C in nitrogen and discharge the material to obtain reduced iron powder Fe-800-2. The obtained product is used for the reduction of m-nitrobenzenesulfonic acid to prepare m-aminobenzenesulfonic acid. The conversion rate and selectivity of the reaction are shown in the tabl...

Embodiment 2

[0021] Example 2: Take a certain amount of iron sludge from the DSD acid production process [Document 2: Wang Fu, Yu Guixiang, Wang Guisheng, Research on a New Method for DSD Acid Preparation, Liaoning Chemical Industry, 1994, 5: 33-35], wash with water until the filtrate The pH was 8, and the solid material was dried at 140°C for 8 hours. Take 20g of dry iron sludge and 0.5g of aluminum oxide, mix them uniformly and put them into the reduction reactor, pass in hydrogen gas with a flow rate of 40mL / min, and raise the temperature from room temperature to 800°C at a constant speed in 60 minutes to carry out the reduction reaction for 3 hours. Then cool to room temperature in nitrogen and discharge the material to obtain reduced iron powder Fe-800-3. The obtained product is used for the reduction of m-nitrobenzenesulfonic acid to prepare m-aminobenzenesulfonic acid. The conversion rate and selectivity of the reaction are shown in Table 1. .

Embodiment 3

[0022] Example 3: Take a certain amount of iron sludge from the production process of p-aminophenol [Document 3: Zhang Yanzhong, Review of p-aminophenol Synthesis Technology, Guangxi Chemical Industry, 1997, 26 (2): 14-19], wash with water until the pH of the filtrate is 8, and then the solid matter was dried at 140°C for 8 hours. Take 20g of dried iron sludge, 0.4g of silicon dioxide and 1.2g of alumina into a reduction reactor, feed hydrogen gas at a flow rate of 40mL / min, and raise the temperature from room temperature to 750°C at a constant rate in 1 hour for reduction reaction for 3 hours. Then cool to 200°C in nitrogen and discharge the material to obtain reduced iron powder Fe-750-3. The obtained product is used for the reduction of m-nitrobenzenesulfonic acid to prepare m-aminobenzenesulfonic acid. The conversion rate and selectivity of the reaction are shown in the table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com