Production process for improving properties of anatase titanium dioxide

Anatase titanium dioxide and production process technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of limited performance improvement, increase in calcination strength, and decrease in calcination strength of anatase titanium dioxide, so as to achieve saving Effects of treatment cost, lower calcination temperature, and shorter time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

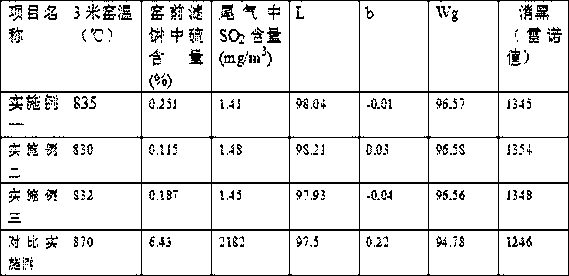

Examples

Embodiment 1

[0034] (1) Take the qualified metatitanic acid slurry for bleaching and washing, and adjust the TiO 2 The content is 245g / L, the temperature is raised to 60°C, the pH is adjusted to 7.0 with ammonia water, and matured for 2 hours;

[0035] (2) After suction filtration and neutralization, the slurry was obtained to obtain a filter cake, and then washed with deionized water for 40 minutes, and the filter cake was beaten to make TiO 2 The content is 253g / L;

[0036] (3) Add potassium hydroxide and phosphoric acid for salt treatment, and then filter with suction to ensure that K in the base material after calcination 2 O content is 0.20%, P 2 o 5 The content is 0.30%;

[0037] (4) The filter cake is calcined in a rotary kiln, and the decolorizing power of 100 is used as the qualified standard for calcining the material, and the sulfur content of the tail gas is tested with a tail gas analyzer.

[0038] (5) Crushing, testing the whiteness and blackening (Reynolds value) of the...

Embodiment 2

[0040] (1) Take the qualified metatitanic acid slurry for bleaching and washing, and adjust the TiO 2 The content is 228g / L, the temperature is raised to 70°C, the pH of the slurry is adjusted to 6.7 with ammonia water, and it is matured for 1.5h;

[0041] (2) After suction filtration and neutralization, the slurry was obtained to obtain a filter cake, and then washed with deionized water for 25 minutes, and the filter cake was beaten to make TiO 2 The content is 263g / L;

[0042] (3) Add potassium hydroxide, phosphoric acid and zinc chloride for salt treatment, and then filter with suction to ensure that K in the base material after calcination 2 O content is 0.20%, P 2 o 5 The content is 0.30%;

[0043] (4) The filter cake is calcined in a rotary kiln, and the decolorizing power of 100 is used as the qualified standard for calcining the material, and the sulfur content of the tail gas is tested with a tail gas analyzer.

[0044] (5) Crushing, testing the whiteness and bl...

Embodiment 3

[0046] (1) Take the qualified metatitanic acid slurry for bleaching and washing, in which TiO 2 The content is 219g / L, the temperature is raised to 80°C, the pH of the slurry is adjusted to 6.0 with ammonia water, and the aging is 0.5h;

[0047] (2) After suction filtration and neutralization, the slurry was obtained to obtain a filter cake, and then washed with deionized water for 15 minutes, and the filter cake was beaten to make TiO 2 The content is 268g / L;

[0048] (3) Add potassium hydroxide, phosphoric acid and zinc chloride for salt treatment, and then filter with suction to ensure that K in the base material after calcination 2 O content is 0.20%, P 2 o 5 The content is 0.30%;

[0049] (4) The filter cake is calcined in a rotary kiln, and the decolorizing power of 100 is used as the qualified standard for calcining the material, and the sulfur content of the tail gas is tested with a tail gas analyzer.

[0050] (5) Crushing, testing the whiteness and blackening (R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com