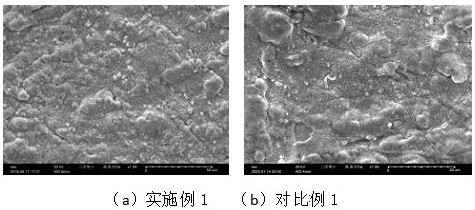

Anti-oxidation carbon-containing zinc impregnation agent and anti-oxidation zinc impregnation process

An anti-oxidation and sherardizing technology, applied in the improvement of process efficiency, metal material coating technology, metal processing equipment, etc., can solve the problem of poor appearance of zinc herring samples, high cost of vacuum herring, and comprehensive performance. Deterioration and other problems, to improve the sintering situation, avoid the surface roughness of the infiltration layer, and reduce the effect of oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of anti-oxidation zincizing process, its operation steps and performance test situation are as follows:

[0037] (1) Prepare the sherardizer according to the mass percentage. Among them, zinc powder accounts for 60%, aluminum powder accounts for 10%, aluminum oxide accounts for 23%, ammonium chloride accounts for 2%, and carbon powder accounts for 5%. The ingredients are weighed and mixed well.

[0038] (2) Dry the zincizing agent. The sherardizing agent obtained in step (1) is placed in a crucible, placed in a sherardizing furnace, and the temperature is gradually increased to 300°C, and kept for 1.5 hours; then the heating is stopped, and the furnace is cooled to 200°C and then air-cooled to room temperature for use.

[0039] (3) Pretreatment of metal workpieces. Q235 steel of 30mm×20mm×3mm is used as the sherardizing workpiece. Use 400#, 800# and 1000# SiC sandpaper to polish the surface to remove oil and rust until a bright metal surface appears on the su...

Embodiment 2

[0045] A kind of anti-oxidation zincizing process, its operation steps and performance test situation are as follows:

[0046] (1) Prepare the sherardizer according to the mass percentage. Among them, zinc powder accounts for 40%, aluminum powder accounts for 15%, aluminum oxide accounts for 40%, ammonium chloride accounts for 2%, and carbon powder accounts for 3%. The ingredients are weighed and mixed well.

[0047] (2) Dry the zincizing agent. The sherardizing agent obtained in step (1) is placed in a crucible, placed in a sherardizing furnace, and the temperature is gradually increased to 400 ° C and kept for 1 hour; then the heating is stopped, and the furnace is cooled to 200 ° C and then air-cooled to room temperature for use.

[0048](3) Pretreatment of metal workpieces. Q235 steel of 30mm×20mm×3mm is used as the sherardizing workpiece. Use 400#, 800# and 1000# SiC sandpaper to polish the surface to remove oil and rust until a bright metal surface appears on the sur...

Embodiment 3

[0053] A kind of anti-oxidation zincizing process, its operation steps and performance test situation are as follows:

[0054] (1) Prepare the sherardizer according to the mass percentage. Among them, zinc powder accounts for 50%, aluminum powder accounts for 8%, aluminum oxide accounts for 38%, ammonium chloride accounts for 2%, and carbon powder accounts for 2%. The ingredients are weighed and mixed well.

[0055] (2) Dry the zincizing agent. The sherardizing agent obtained in step (1) was placed in a crucible, placed in a sherardizing furnace, and the temperature was gradually increased to 250°C, and kept for 2 hours; then, the heating was stopped, and the furnace was cooled to 200°C, and then air-cooled to room temperature for use.

[0056] (3) Pretreatment of metal workpieces. Q235 steel of 30mm×20mm×3mm is used as the sherardizing workpiece. Use 400#, 800# and 1000# SiC sandpaper to polish the surface to remove oil and rust until a bright metal surface appears on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com