Method for enzymatic synthesis of theaflavin TF by virtue of tea polyphenol oxidase isoenzyme PPO1

A tea polyphenol oxidase isoenzyme and enzymatic synthesis technology, which is applied in the field of theaflavin TF preparation, can solve the problems of large differences in biological activities of theaflavin components, diverse enzymatic synthesis products, and theaflavin components. The problem of high cost is to avoid the tedious separation and purification process, improve the utilization rate of the substrate, and achieve the effect of a single product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Tea polyphenols are dissolved in citric acid-disodium hydrogen phosphate buffer solution with a pH value of 5.5 to prepare a tea polyphenol solution with a mass volume concentration of 1.2%.

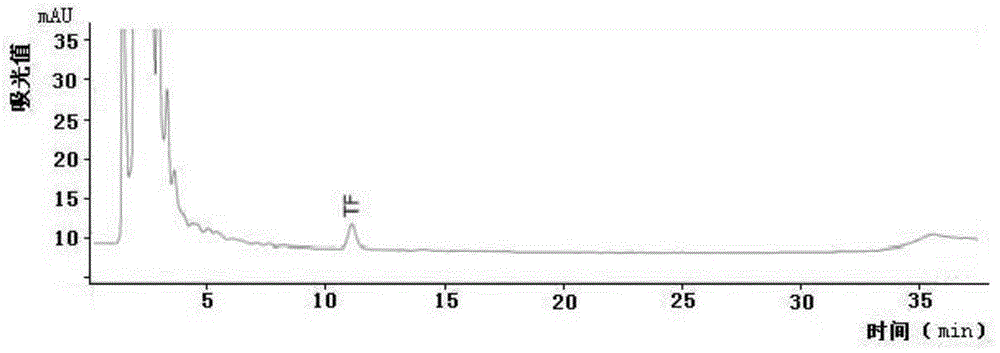

[0030] Take 1ml of tea polyphenol oxidase isoenzyme PPO1 enzyme solution with an enzyme activity of 4340U / ml, add it to 500ml tea polyphenol solution with a mass volume concentration of 1.2%, use air as the source of oxygen for enzymatic synthesis, at 36°C After oscillating on a shaker at 60r / min for 60min, immediately use ethyl acetate equal to the volume of the reaction solution to stand for extraction for 5min, and the extract was centrifuged at 1500r / min for 3min, and the ethyl ester layer solution of the organic phase was taken for the inorganic phase The solution part was extracted once again by repeating the above operation, centrifuged, and the organic phase ethyl acetate solution obtained twice was combined, and the ethyl acetate solution was vacuum concentrated and recove...

Embodiment 2

[0032] Tea polyphenols are dissolved in sodium acetate-acetic acid buffer solution with a pH of 4.5 to prepare a tea polyphenol solution with a mass volume concentration of 3.0%.

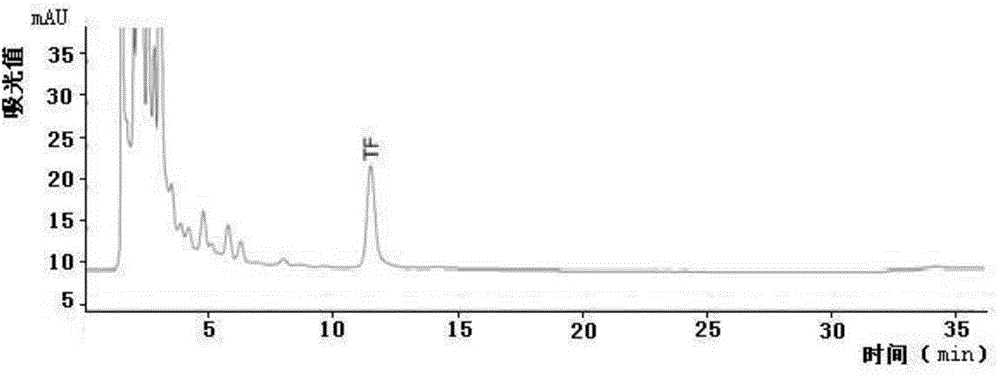

[0033] Add 1ml of tea polyphenol oxidase isoenzyme monomer PPO1 enzyme solution with an enzyme activity of 4340U / ml to 650ml tea polyphenol solution with a mass volume concentration of 3%, and use air as the oxygen source for enzymatic synthesis at 20°C After oscillating on a shaker at 90r / min for 45min under certain conditions, immediately use ethyl acetate equal to the volume of the reaction solution to stand for extraction for 20min, and the extract is centrifuged at 3000r / min for 1min, and the ethyl ester layer solution of the organic phase is taken for the inorganic For the phase solution part, repeat the above operation to extract and centrifuge once again, combine the organic phase ethyl acetate solution obtained twice, concentrate and recover ethyl acetate under the condition of vacuum degree...

Embodiment 3

[0035] Tea polyphenols were dissolved in Tris-HCl buffer solution with a pH of 6.5 to prepare a tea polyphenol solution with a mass volume concentration of 2.1%.

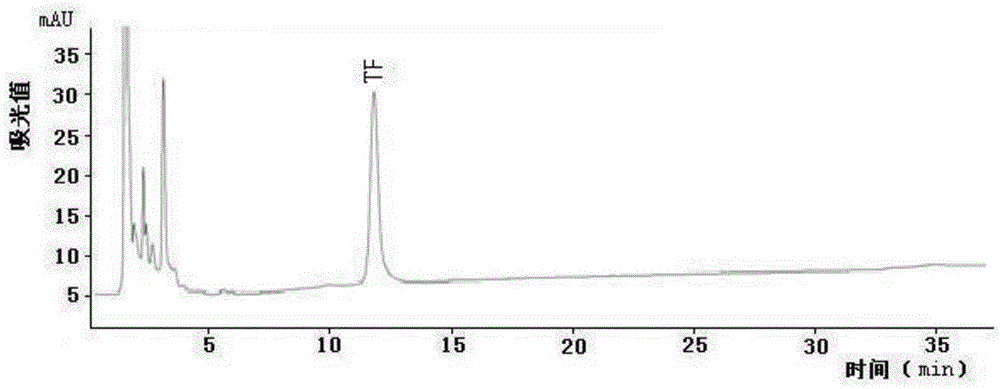

[0036] Add 1ml of tea polyphenol oxidase isoenzyme monomer PPO1 enzyme solution with an enzyme activity of 4340U / ml into 800ml tea polyphenol solution with a mass volume concentration of 2.1%, and use air as the source of oxygen for enzymatic synthesis. After oscillating on a shaker at 150 rpm at ℃ for 30 min, immediately use ethyl acetate equal to the volume of the reaction solution to stand for extraction for 30 min, then centrifuge the extract at 500 r / min for 5 min, take the ethyl ester layer solution of the organic phase, and For the inorganic phase solution, repeat the above operation to extract and centrifuge once again, combine the organic phase ethyl acetate solution obtained twice, and concentrate and recover ethyl acetate under the condition of vacuum degree of -0.075Mpa and temperature of 55°C, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com